The product range from a two-ton hexapod to a ten-gram nanopositioner requires that PI can both manufacture and qualify these systems. For this reason, PI operates a heavy duty hall at its location in Karlsruhe for the assembly and measurement of masses up to five tons. Here, three gantry cranes span the working area and lift and transport the components of the positioning systems.

A ground granite slab with a smoothness of 3.8 µm acts as assembly area. Air-cushioning elements also decouple the granite slab against external vibration. This already allows precise alignment of the axes of a positioning system during assembly. A further granite slab with a surface precision of 5.2 µm is employed as measuring plane for the measurement of the products.

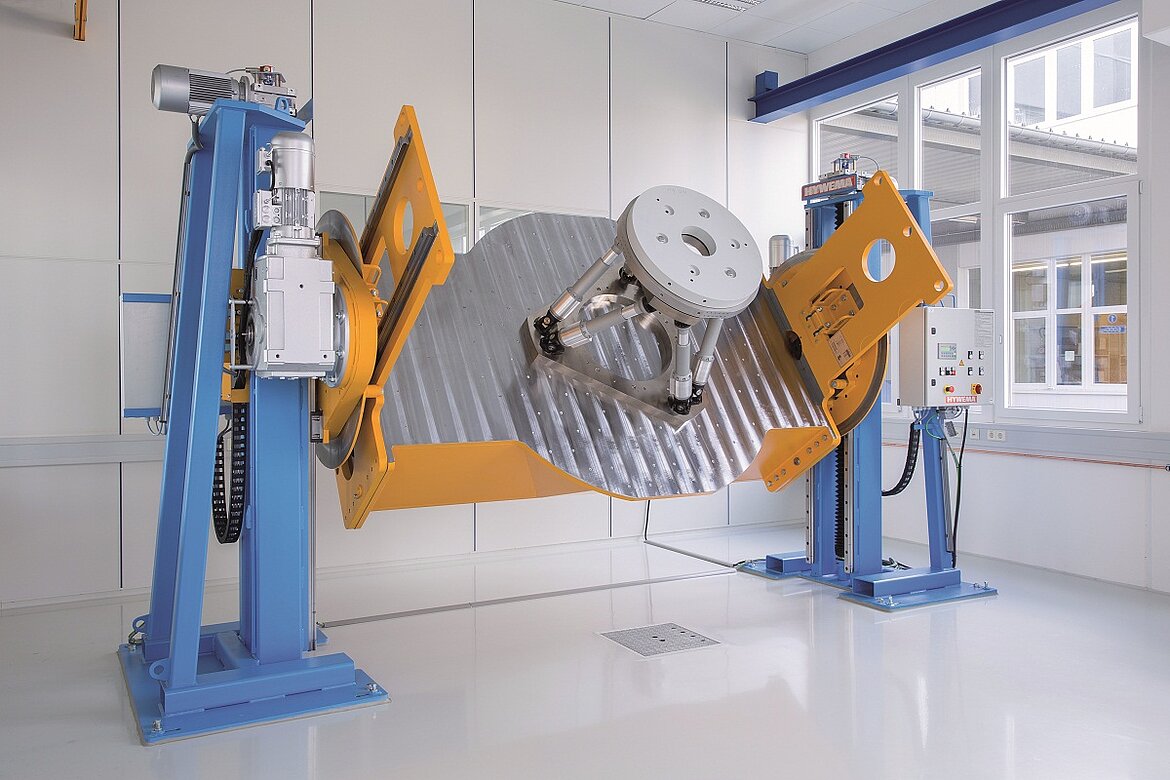

The lifting and rotating equipment allows infinite rotation of payloads up to seven tons around 360°. To give an example, this allows qualification of the behavior and specifications of heavy duty hexapods in a customer-relevant installation environment. As both the product to be measured and the measuring device are mounted, PI ensures that only the actual motion of the products is measured.