Piezo Custom Assemblies, Miniature Piezo Transducers, Working with OEM's, Instrumentation Manufacturers

Developing and manufacturing piezo ceramic materials and components are complex processes. PI Ceramic - PI’s piezo material design and manufacturing facility - boasts several decades of experience as well as the right tools for rapid prototyping of custom engineered piezo components and assemblies. From the formulation of advanced piezo materials to the processing steps such as cutting, milling, grinding, and the precision assembly, every stage is controlled by our engineers and product specialists.

Learn about Piezoelectric Materials

Download the Piezoelectric Solutions catalog

Close Cooperation with Our Customers from the Prototype to Large Production Runs

PI Ceramic's process control allows the transition from test samples to large production runs in a reliable and cost-efficient way while maintaining the high quality our products are known for. PI Ceramic has a track record of working closely with OEM instrumentation manufacturers. Our engineers have the knowledge and experience to analyze the requirements and understand the application. They work with our customer's engineers to find the best standard product or design a custom part or assembly.

Based on expertise gained in more than 40 years of continuous research and manufacturing of piezoelectric material and components, PI Ceramic can provide world-class high-performance piezoelectric actuator and transducer components and subassemblies.

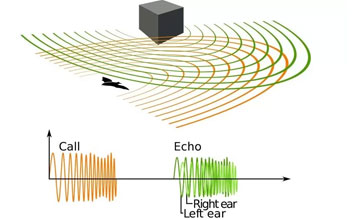

Transducers / Sensor Components

PI Ceramic supplies complete ultrasound transducers in large batches for a wide variety of application fields.

Tech Articles & Applications:

Ultrasonic Piezo Transducers: From Welding to Medical Applications

Piezo Transducers, Actuators, and Motor Drive Solutions for Medical Engineering

These include OEM assemblies for metrology such as level measurement technology, flow measurement, and medical applications such as air bubble detection. Other examples are force and acceleration measurement.

Tech Articles & Applications:

Piezo Transducers in A380 Airbus

Value Added Manufacturing: Piezo Ceramic Products in Different Levels of Integration

PI Ceramic's value added manufacturing saves customers valuable time while letting them concentrate on their core business. From applying custom end pieces, to encapsulation, attachment of leads, custom cables and connectors, through to complex integration jobs of customer-supplied components, PI Ceramic's custom assembly and manufacturing expertise will make you more successful with your product. The bottom line is shorter time-to-market, reduced cost, and significantly simplified in-house manufacturing processes.

PI Ceramic Manufacturing & Assembling Technologies

PI Ceramic provides a great variety of innovative piezo actuator configurations, an ideal basis for further integration and customization. Multilayer actuators come in all kinds of shapes and geometries, even stacks with aperture are available in multilayer configuration. For high force applications classical actuators made from layers of bulk material are available, in stacked or bimorph bender configurations.

Actuators can be equipped with temperature sensors or position feedback sensors to make them suitable for repeatable closed-loop positioning with nanometer accuracy. Piezo actuators are often integrated into mechanical systems, fast switches, valves, pumps or positioners where lever amplification increases the travel range of the piezo ceramic element. Flexure guiding systems then provide high stiffness and minimize the lateral offset.

Piezo Technology Fundamentals

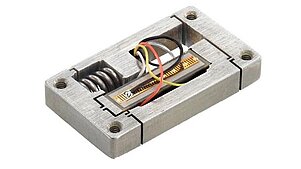

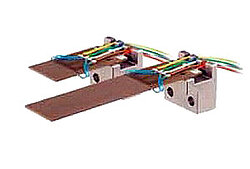

Flexure Assemblies / Preloaded Actuators / Levers / Nanopositioners

PICMA® piezo actuators from PI Ceramic are the key component for nanopositioning systems from Physik Instrumente (PI).

They are supplied in different levels of integration: As simple actuators with optional strain gauge sensors, encased with or without preload (for tensile forces), with lever amplification for increased travel, through to high-performance nanopositioning systems where piezo actuators drive up to six axes by means of zero-wear and frictionless flexure guides.

Piezo Electric Motor Assemblies

Piezo ceramics are the drive element for PI's multiple lines of piezomotors. PILine® piezo ultrasonic motors allow very dynamic motion and can be packaged in extremely small positioners.

Piezo stepping drives provide high forces and picometer resolution. The patented NEXLINE® and NEXACT® drives from PI are based on coordinated motion of longitudinal, shear and bender elements.

PIShift® drives are based on the stick-slip effect and were designed for cost-sensitive applications.

Piezo Manufacturing Process

More information on the Piezo Manufacturing Process at PI Ceramic

Extreme Reliability: When 10 Billion Cycles are not Enough

PICMA® actuators were tested by NASA's Jet Propulsion lab and selected for the Mars Mission. The actuators had to undergo rigorous testing surviving 100 Billion cyles (100,000,000,000) without failures. They are employed in the ChemIn instrument on the Mars Rover Curiosity.

No other piezo supplier can provide quality and innovative actuator solutions similar to PI Ceramic.

Piezo Testing Process

Learn about PI Ceramic's Testing Procedures for Qualifying Piezo Elements

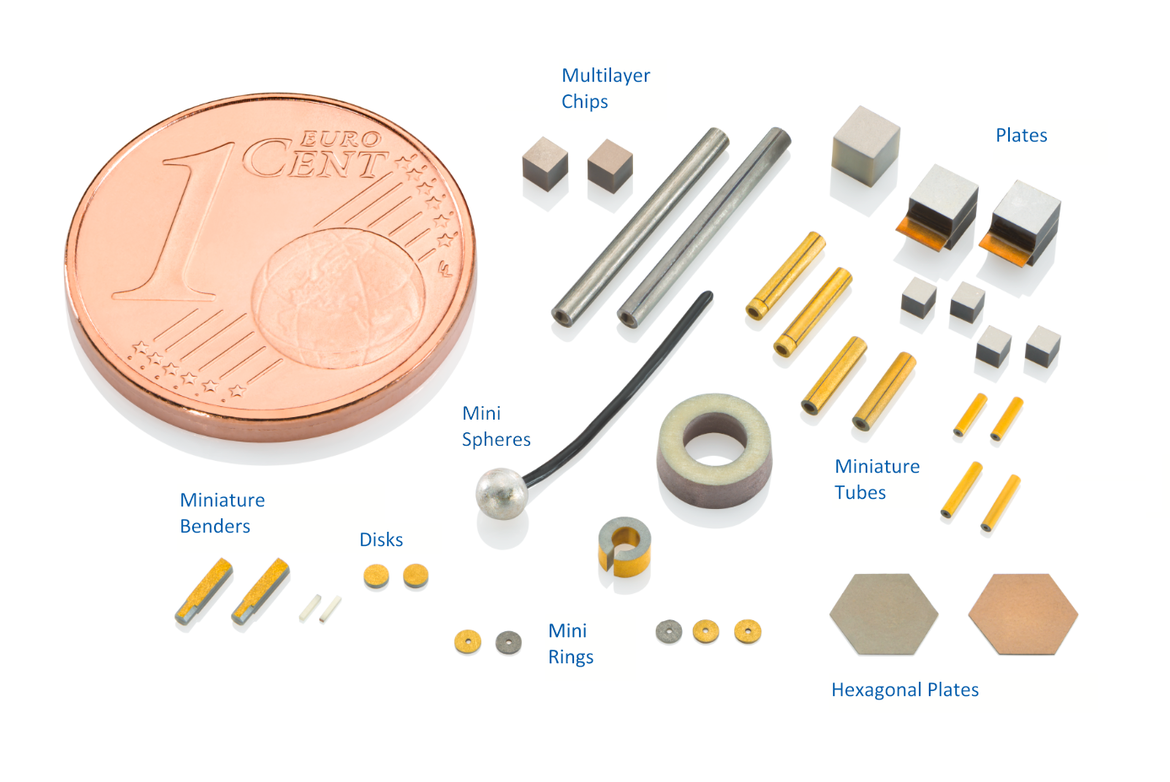

The ongoing miniaturization of piezo transducers opens up new opportunities in medical device manufacturing. PI’s piezo transducer division PI Ceramic has experience in the design and manufacture of miniaturized piezo transducers with both traditional pressing and multi-layer tape casting technology.

Components with external dimensions below 1mm can be produced. Miniaturized sensor and actuator elements can be found in novel scanning catheter endoscopes or in active implants that regulate the internal eye pressure.