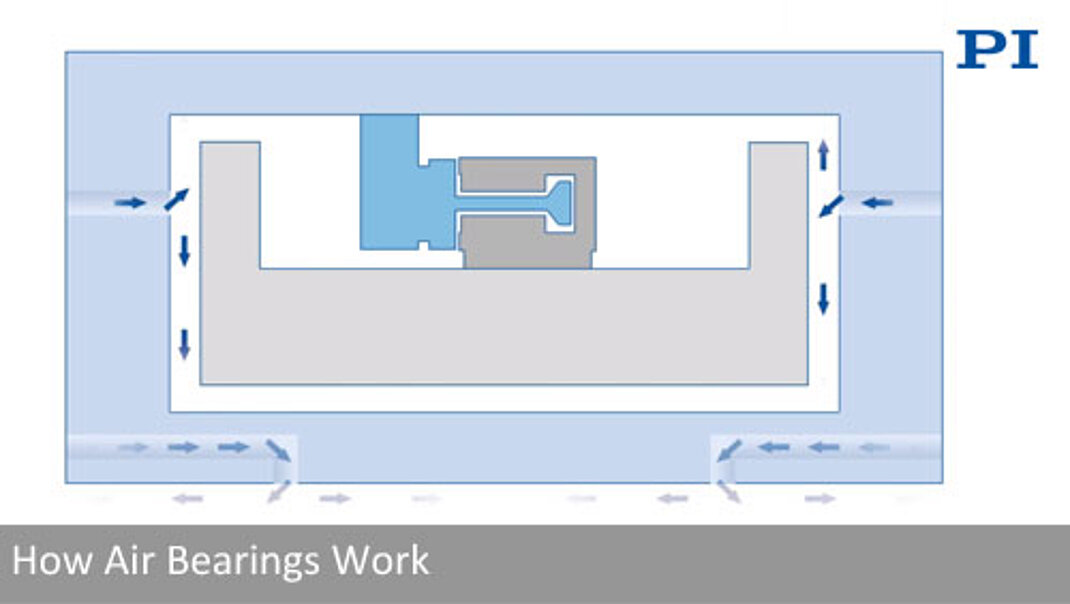

Air bearings provide advantages over mechanical bearings when vibration-free motion is required, highly constant velocity control is crucial, and when angular repeatability and geometric performance must be optimal. Air bearing stages replace mechanical contact by a thin air film, avoiding wear, friction, vibration, and hysteresis effects. PI offers linear air bearing slides, XY air bearing tables, rotary tables / spindles, tip-tilt stages and 3-degree-of-freedom spherical air bearings. Combinations of linear and rotary stages are available to provide 1, 2, 3, 4, 5, and 6 axis air bearing solutions.

PI offers the broadest and deepest portfolio of precision motion technologies. PI’s US operation has extensive experience with the design and manufacture of Air Bearing precision positioning products. PI is building on over 200 years of in-house air bearing experience to offer linear, planar XY, and rotary air bearing stages to serve the OEM, industrial, and research markets. PI US also has its own precision grinding facility located in Nashua, NH. The global PI group offers comprehensive precision air bearing motion control and positioning products and systems, which are inherently frictionless, for smooth accurate motion.

By combining extremely responsive engineering support and lean manufacturing techniques, PI is able to provide the highest quality service to its customers. Maximum performance of precision systems is achieved through extensive design and analysis expertise, using in-house built equipment and proprietary techniques.

In addition to a variety of standard air bearings and motorized positioning stages, fully integrated custom-designed multi-axis positioning systems for metrology and machining applications are available from PI’s US design and engineering team. ACS (part of the PI group) motion controllers are our primary controllers; we have experience with many other controllers, if the customer prefers a different brand.

For more information on PIglide air bearing technology, download our air bearing catalog.

These stages use ironless cog-free 3-phase linear motors or voice coil motors, integral optical linear encoders and non-contact fully preloaded air bearings. Some models come with a choice of sine/cosine, A/B and absolute BISS encoders.

A-142 Mini Voice Coil Linear Slide

Air Bearings, Frictionless, Fast

- 10mm travel

- 3kg load

- 5nm encoder, 0.1µm straightness

- 75x80mm table; 27mm height

- 450mm/sec, 2g acceleration

- 20N push/pull force

A-143 Compact Air Bearing Stage

Ideal for Photonics Alignment

- 25mm travel

- 4kg load

- 1nm absolute sensor

- 75x85mm table; 40mm height

- 3.9m/sec max. velocity

- 1g max. acceleration

A-141 Miniature Air Bearing Stage

Ultra-Compact Air Bearing Stage

- 40mm travel

- 3.5kg load

- 20nm resolution

- 57x83mm table; 38mm height

- 0.25m/sec max. velocity

- 0.35g max. acceleration

A-110 PIglide Air Bearing Stage

Affordable Design, Travel to 16”

- 2/4/8/12/16” travel

- 10kg load

- 1nm resolution, abs/enc option

- 160x200mm table; 60mm height

- 1m/sec max. velocity

- 2g max. acceleration

A-121 PIglide Air Bearing Stage

Travel to 14”

- 2/4/6/10/14” travel

- 10kg load

- 1nm resolution, abs/enc option

- 115x115mm table; 60mm height

- 1m/sec max. velocity

- 2g max. acceleration

A-123 PIglide Air Bearing Stage

Large, Travel to 30”

- 2/4/6/10/14/20/30” travel

- 10kg load

- 1nm resolution, abs/enc option

- 210x210mm table; 85mm height

- 1m/sec max. velocity

- 3g max. acceleration

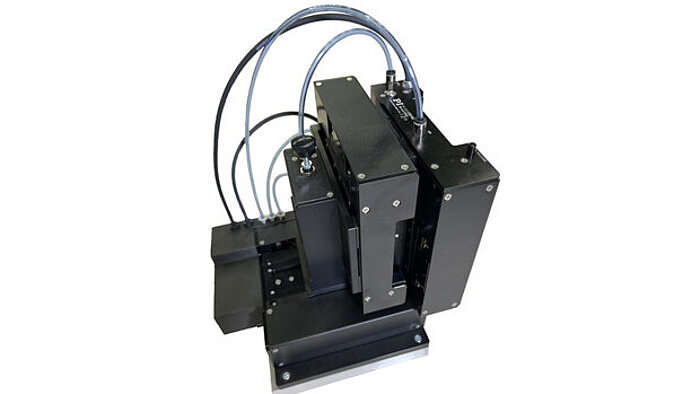

A-131 Voice Coil Positioner

For Fast Scanning/Autofocus

- 1” travel

- Optional bellows

- 1nm resolution

- 8g max. acceleration

Z-Stages, Counterbalanced

Custom Examples

- Air, spring, mechanical, and magnetic counterbalance options

- Custom bridge and gantry designs

A-123.Z Vertical Air Bearing Stage

Pneumatic Counterbalance

- 50, 100, 150mm motion

- 3-Phase linear motor

- Adjustable Z-counterbalance

- 10kg max. vertical load

- Linear encoder

5-Axis Air Bearing Wafer Stage

Watch Video

This 5-axis stage is based on the A-311, planar XY stage and the A-523, 3-Axis Z, Theta-X, Theta-Y stage. Applications are in semiconductor and laser processing.

3-Axis Nanopositioning / Alignment Stage

Watch Video

This compact XYZ nanopositioning stage provides high dynamics and is ideal for fast scanning and alignment applications in 24/7 automation.

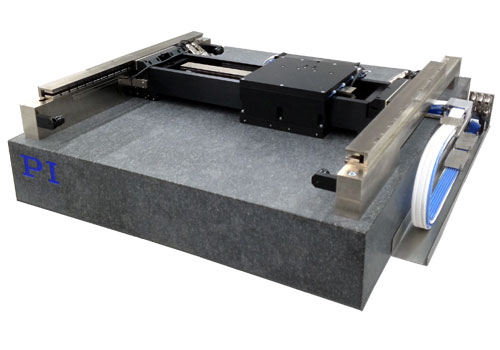

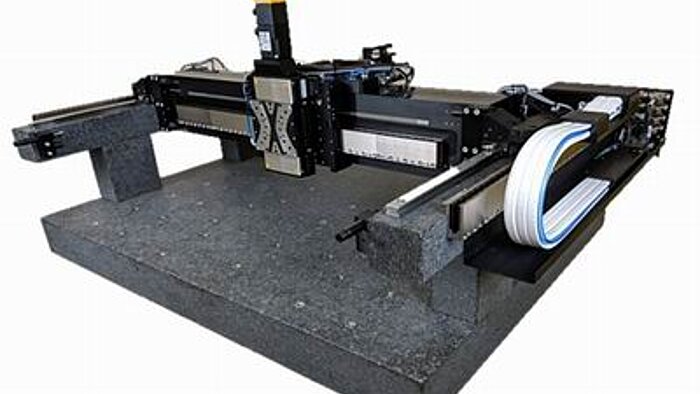

Planar multi-axis air bearing stages provide additional advantages compared to mechanical bearing stages. Due to one common base for the X and Y axes torque and bending moments do not exist and will not influence the geometric performance (straightness, flatness) of the XY motion. The A322 three motor stage incorporates active yaw control using three motors and a flexural coupling element. In addition to linear motions in the X and Y axis, a small amount of rotational motion in theta Z is possible.

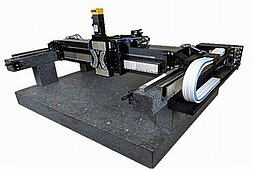

A-322 Planar Air Bearing Stage

3&4-Motor Designs, Granite Base

- 3 Models: Base, Plus, Ultra

- 500x1000mm max. travel

- 15kg load

- 1nm resolution

- Active yaw control flex coupling

- Dynamic error mapping

- 1m/sec / 2g max. acceleration

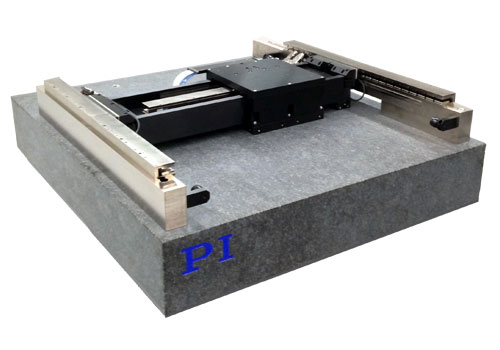

A-311 Planar Air Bearing Stage

Compact, Affordable, Al Base

- 50x50mm to 300x400mm travel

- 15kg load

- 1nm resolution

- Light weight, AL base

- Dynamic error mapping

- 2m/sec / 2.7g max. acceleration

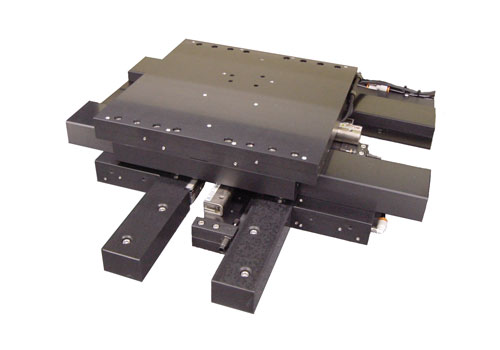

PIglide XY Air Bearing Stage

Stacked XY Combinations

- Various travel ranges

- 10kg load

- 1nm resolution

- Dynamic error mapping

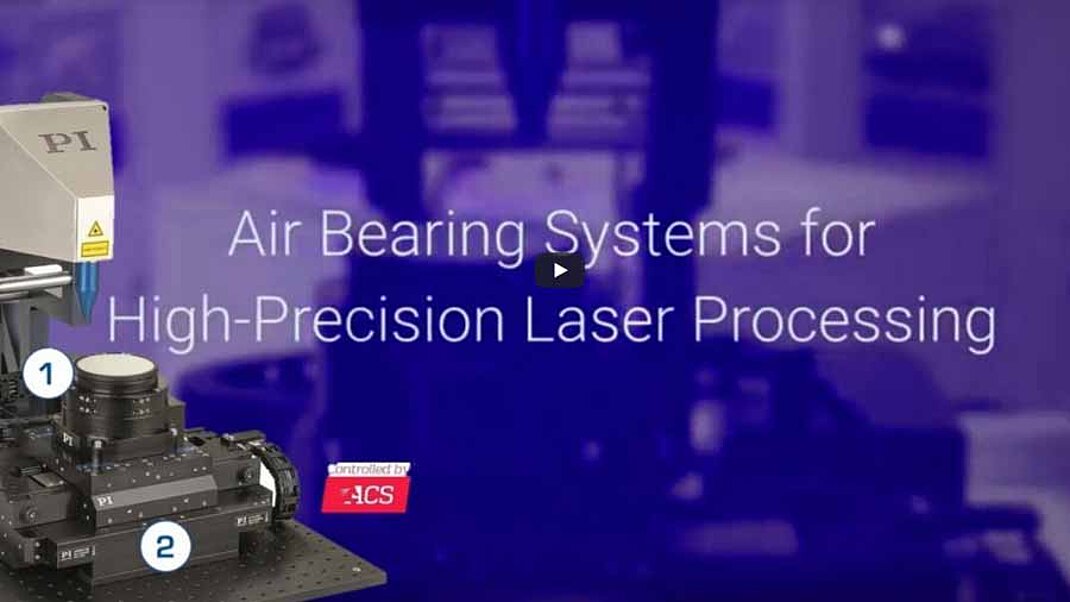

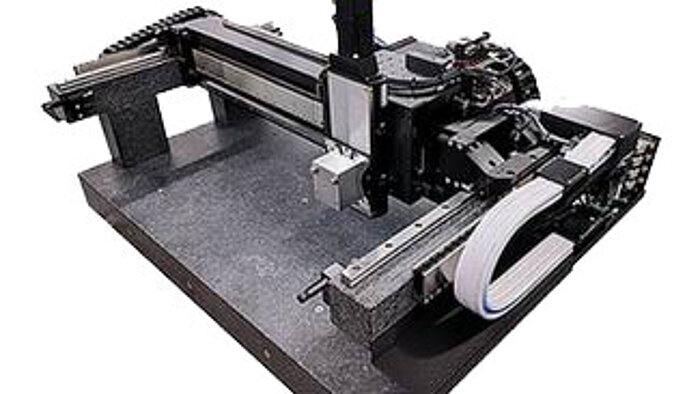

XYZ Laser Processing Stage

XY Air Bearing + Mechanical Z

- 100x100mm to 300x400mm XY travel

- 25mm Z-travel

- High-performance motion controller

- Optional LCM laser control module

F-143 Air Bearing Multi-Axis Alignment System

High Performance Controller and Alignment Algorithms

- Zero-wear, air bearing-based, compact, photonics alignment platform

- Controller with embedded high-speed algorithms for out-of-the-box alignment and tracking

- Open-source LabVIEW code and host programming libraries for easy development

- Non-contact linear motors on all axes enabling higher-throughput and lifetime

- 25mm travel, 1nm resolution, XY and XYZ configurations

- Integrated brake and non-contact counterbalance on the vertical axis

- Optional high-performance power meter

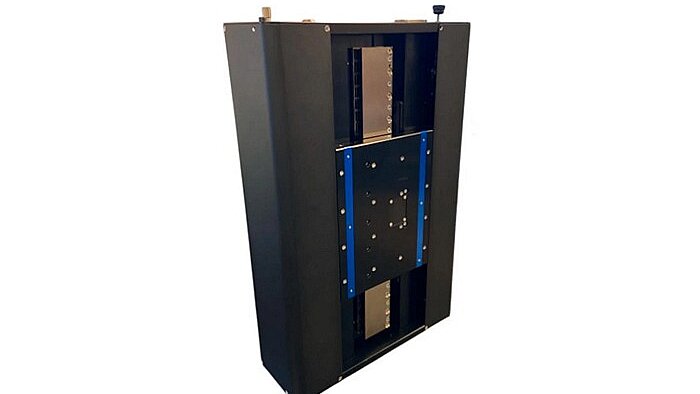

A-341 Hybrid XY / XYZ Gantry Stage

Air Bearings & Linear Bearings, Linear Motors

- 300x300 to 500x1000mm XY travel

- 10kg load

Absolute encoders, 1nm resolution

- Z-Stage options: linear motors or ball screws

- Dynamic error mapping

- 2m/sec max velocity (cross axis)

A-351 Overhead XY / XYZ Gantry Stage

Linear Bearings, Linear Motors

- 300x300 to 500x1000mm XY travel

- 20kg load

Absolute encoders, 1nm resolution

- Z-Stage options: linear motors or ball screws

- Dynamic error mapping

- 2m/sec max velocity (cross axis)

A-352 Large XY / XYZ Gantry Stage

Linear Bearings, Linear Motors

- 750x750 to 1000x2000mm XY travel

- 30kg load

- Absolute encoders, 1nm resolution

- Z-Stage options: linear motors or ball screws

- Dynamic error mapping

- 2m/sec max velocity (cross axis)

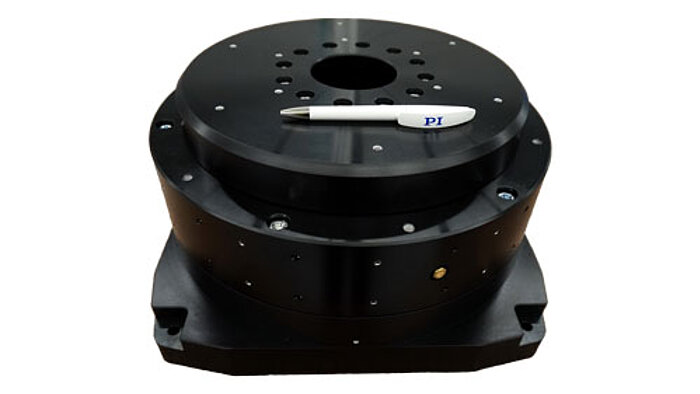

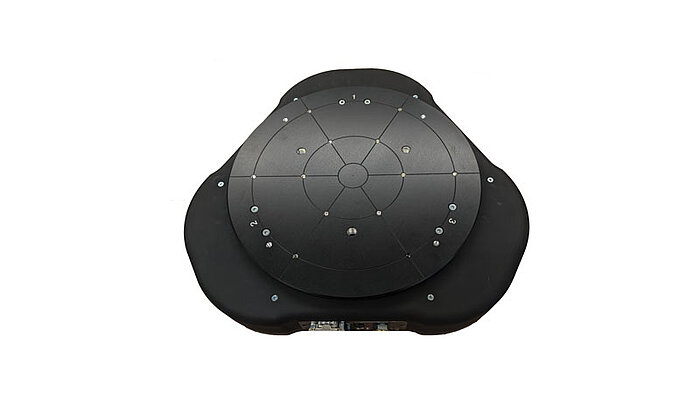

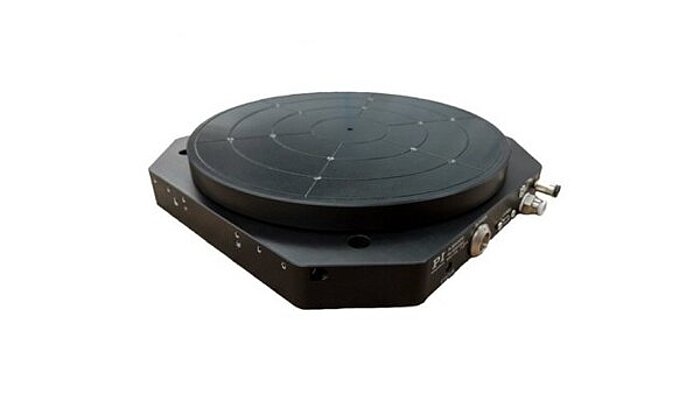

A-621, A-623, A-624, A-627 PIglide RM motorized rotary air bearing stages can be used in any orientation, while the low profile series of A-635/A-637 stages are designed for horizontal use. PIglide rotary stages feature high performance, low-cogging frameless slotless torque motors, and optical encoders. Various options can be combined to create a solution ideal for point-to-point indexing or constant velocity scanning. Applications include optical alignment, metrology, inspection, calibration, and scanning. These stages offer superior runout, flatness, and wobble performance. Since they are completely frictionless, they exhibit no breakaway “stiction” or drag friction during operation. They are ideal for use in cleanrooms, require no maintenance or lubrication, and have unlimited life.

A-621 - A-627 Air Bearing Rotary Stages

Direct Drive, High Load

- 2/4/6/8/12” table diameter

- 13 to 420kg load

- 0.008µrad max. resolution

- 40 to 100nm flatness

- 500 to 2500 RPM max.

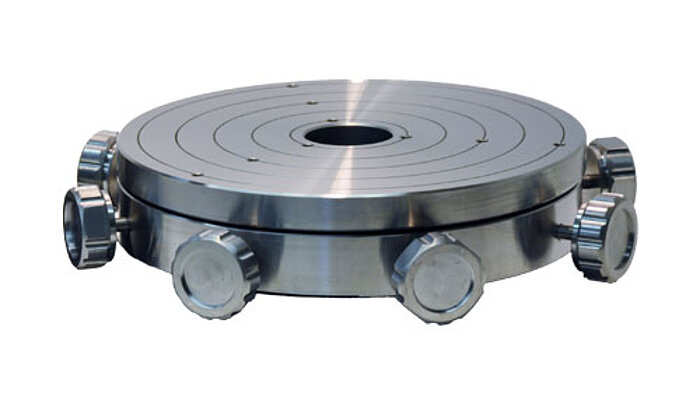

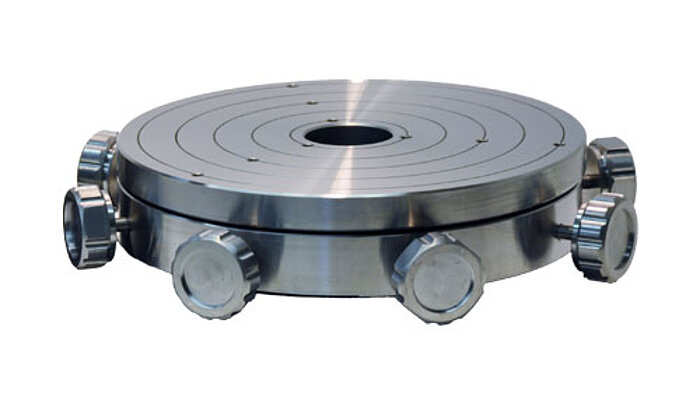

A-634 – A-638 Air Bearing Rotary Stages

Low Profile, Large Diameter

- 6/8/14” table diameter

- 20/32/60/120kg load capacity

- 0.03µrad max. resolution

- <100nm eccentricity & flatness

- 500 RPM max.

- Self-locking option at rest

A-523 Z-Tip-Tilt Air Bearing Stage

Low Profile

- ⌀250mm table

- 8 kg load capacity

- 5mm Z-stroke, to 2° tip/tilt

- 10nm/0.06µrad incremental motion

- 1nm sensor resolution

A-361 X-Y-θ Air Bearing Alignment Stage

Voice Coil Driven, Low Profile

- 5mm x 5mm x 2° Travel

- 40mm height, ø200mm

- Air Bearings & Voice Coils

- Parallel Kinematics

- Lock-down Capable

- 6-DOF Option

These high performance controllers feature state of the art ACS SPiiPlusEC motion control modules and EtherCAT® master, and includes ServoBoost™ for up to eight axes of motion. ServoBoost™ provides better, more consistent servo performance that is insensitive to noise or (load) changes in the system.

A-824/6/8 PIglide Motion Controller

High Power: 4, 6 & 8 Motion Axes

- Fully integrated closed-loop servo, amplifier module & power supplies

- 2000 W continuous, 3900 W peak

- 3-Phase BLDC / voice coil / DC

- Quiet PWM drives

- Sine/cosine and BiSS-C encoders

- 20A peak output current/axis

A-811/2/4 PIglide Motion Controller

Compact: 1, 2 & 4 Motion Axes

- Fully integrated closed-loop servo, amplifier module & power supplies

- 600W power supply

- 3-phase BLDC / voice coil / DC

- Quiet PWM drives

- Sine/cosine and BiSS-C encoders

- 10A Peak output current/axis

A-811 PIglide Motion Controller

1-Axis Benchtop Version

- Fully-integrated servo-controller with drive

- Compact benchtop device, external AC/DC-P/S

- For 3-phase / voice coil / DC motors

- Quiet PWM drives

- Sine/cosine and BiSS-C encoders

- Functional safety: STO (Safe Torque Off)

Motion Controller Adapts to Different Loads in Real Time: ServoBoost™ from ACS

Watch Video

An advanced algorithm called ServoBoost™ in ACS motion controllers automatically adapts the servo settings to load changes in real time.

A-101 - A-109 Linear Air Bearings

Non Motorized Linear Slides

- 50 to 1000mm range

- 9 table sizes: 50x50 to 300x300mm

- 13 to 760kg vertical load

- 7.5 to 21kg lateral load

- Excellent straightness/flatness

A-411 Flat Pad Air Bearings

Frictionless Linear / Planar Motion

- 25 to 300mm diameter

- 8 to 1500kg load

- 17 to 860N/µm stiffness

A-601 – A-607 Rotary Air Bearings

Non Motorized, Encoder Options

- Ideal for optics testing

- 2/3/4/6/8/12” table diameter

- 13 to 420kg axial load

- 5 to 270kg radial load

- 75 to 300nm eccentricity

- Optional high resolution encoder

A-651 - A-657 Spherical Air Bearings

3 Degrees of Freedom

- Ideal for zero gravity simulation

- 2/3/4/6/8/10/12” sphere diameter

- 15 to 635kg load

- ±45 degrees rotation range

A-60x.MTT Manual X-Y-Tilt Platform

Add-On For Rotary Stage

- Ideal for optics testing

- 4 degrees of freedom: X, Y, θX, θY

- Manual operation

- Travel to ±3mm, ±1.25°

- 3/4/6/8/10” table diameter

- Direct mount on A-60x / A-62x

A-65x.PED Pedestal

For Spherical Air Bearings

- Works with A-651 to A-657

- Ideal for satellite control and simulation of weightlessness

A-80x PIglide Preparation Kits

Pressure Control & Air Filtration

- Cleans & filters compressed air

- Controls the supply pressure

- Optional pressure switch

- Recommended for all PIglide products

- Customized adaptations

A-10x Mounting Feet

For PIglide Linear Air Bearings

- For A-101 - A-109 linear air bearings

- Hardcoat aluminum

A-60x.MTT Manual X-Y-Tilt Platform

Add-On For Rotary Stage

- Ideal for optics testing

- 4 degrees of freedom: X, Y, θX, θY

- Manual operation

- Travel to ±3mm, ±1.25°

- 3/4/6/8/10” table diameter

- Direct mount on A-60x / A-62x

Application Examples of Air Bearings, Stages and Systems

PI's air bearing products serve the needs of a wide variety of applications and industries. Below are examples of diverse problems that were solved with PI products.

PI air bearing products can be used to build metrology systems for roundness, flatness, surface profile, or thickness measurements. When precision manufactured parts need to be measured to the tightest tolerances in aerospace, aircraft, automotive, ball bearings, infrared and precision optics, semiconductors, or turbines, contact a PI engineer to help design your system.

Contact a PI engineer to discuss research and development applications. PI's broad range of positioning and control products can be integrated into almost any configuration imaginable to help reach the next breakthrough.

As flat panel displays (FPDs) continue to grow in size and improve image resolution, the demands on test and inspection equipment continue to become more challenging. PI's planar air bearing stages and gantries can be customized to meet incredibly tight precision specifications over very long travels.

PI offers sophisticated equipment for high-end scientific research in large-scale synchrotron and accelerator research facilities. Linear slides and rotary air bearing spindles are used to position sensors and instrumentation in various beamline applications, including tomography and holography, micro-CT positioning, sample adjustment, microscopy, and X-Ray scanning.

Digital printing demands fast, accurate motion with precise velocity control and very low angular motion errors. PI's long travel linear air bearings are the key to leading manufacturer's digital print to film high resolution printer setters. Lightweight bearings deliver over one meter of travel with a straightness accuracies as low as 3 µm. The system achieves excellent velocity stability, resulting in exceptional print quality.

Optical grinding requires extremely precise and smooth motion in order to achieve demanding tolerances for surface finish. When leading optical manufacturers need a rotary spindle with run-out and flatness errors less than 0.1µm for integration into their custom grinding machine, PI provides the solution. In addition to excellent accuracy, the outstanding stiffness of air bearing spindles allows the bearing to withstand forces without a degradation of positioning accuracy and repeatability.

Tensile testing machines apply precise forces, under high loads at zero velocity. Rolling element bearings exhibit significant breakaway friction which causes irregularities in the applied force. PI supplies major test equipment manufacturers with entirely non-contact, linear motor-actuated stage solutions for tensile testing machines. Due to PI's extensive experience with assembling to extremely tight tolerances, complex assemblies are delivered with higher quality and lower cost than manufacturers can achieve in-house.

Leading manufacturers of high resolution laboratory spectrometers require custom linear air bearings that provide extremely precise, tilt-free, smooth motion for their scanning mirrors. PI's totally non-contact assemblies deliver the reliability and minimal maintenance today's laboratory users demand.

Satellite systems attitude control research often requires simulation of a zero-g environment. PI's spherical air bearings have solved this problem for government and commercial research agencies. PI delivers complete systems, including mounting pedestals and air handling equipment, that support significant loads with a large range of motion.

Semiconductor processing equipment must operate with high reliability and minimal particle generation. Unlike traditional bearings, non-contact air bearings deliver exceptional reliability and lifetime with zero maintenance. Operating on a clean air or nitrogen supply, no particles are generated. This is why leading manufacturers of semiconductor processing equipment use PI air bearings for a variety of wafer inspection, handling, and transport applications.

PI developed custom linear air bearings in response to the need of major auto manufacturers for high load capacity air bearings for vehicle testing. Air bearings support heavy loads without the binding and high friction, typical of traditional bearings. As a result, multiple uses of automotive applications have been found, such as suspension testing and racecar suspension tuning.

Micro-machining and nano-manufacturing require ultra-precision, smooth motion, high stiffness, and dynamic motion. An air bearing motion system combines all these aspects. Combine linear motion with a voice-coil stage for a fast-tool servo system, or add a spindle for machining applications. Optional bellows covers can be added to protect the stages from dust and debris.