“This technology promises to improve alignment time by orders of magnitude. It is outpacing any other technique currently used for automated photonics alignment in the market.” In this interview, Nikta Jalayer, Director of Business Development, talks about how the engineers at PI’s Silicon Valley Tech Center solved the first light detection problem in photonics alignment.

This new technology dramatically shortens time scales required for precision alignment and test of photonics devices.

Photonics is at the core of our activities, and we’ve been challenged by our customers to solve the first light detection problem which presents a major bottleneck in Silicon Photonics test and assembly. Photonic devices are playing an ever-increasing role in allowing us to interact with the world and each other. But until now, photonics growth has been held back by legacy methodologies and hardware. Needed is new technology capable of testing and assembling photonic circuits in production, at scale.

At PI’s Silicon Valley Technology Center in Fremont, California, the genesis of a new technology has emerged, a technology that dramatically shortens time scales required for precision alignment and test of Photonics devices and other automated signal searches.

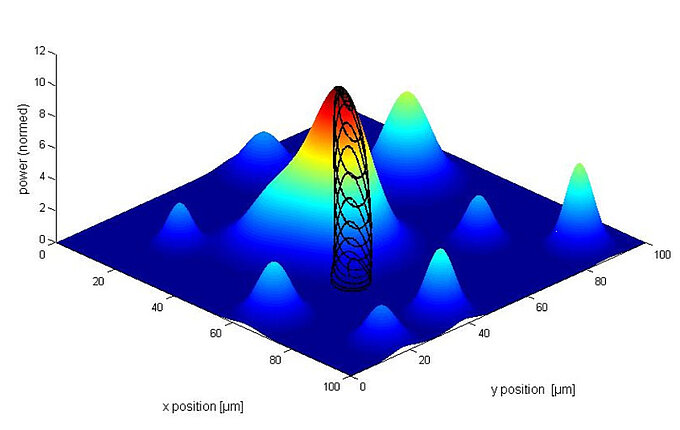

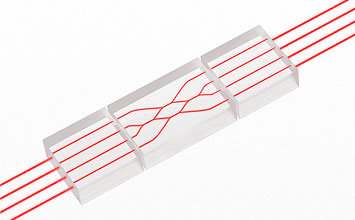

We went to first principles and thought about search in the macroscopic world. Which when viewed in certain lights is wildly different than the existing photonics signal search paradigm in concept. We conceived of a new search method based on an in-depth understanding of active piezo ceramics – effectively building a bridge from the macro world and into microscopic search.

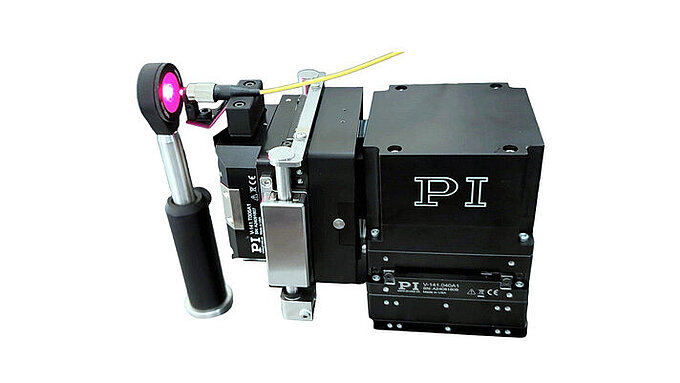

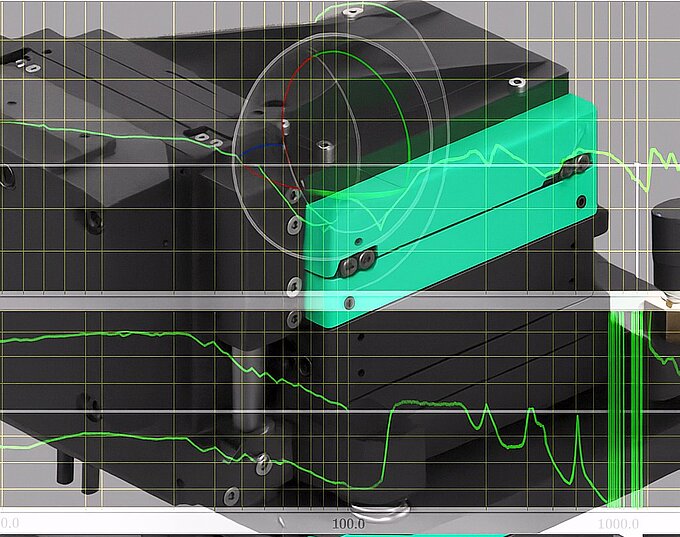

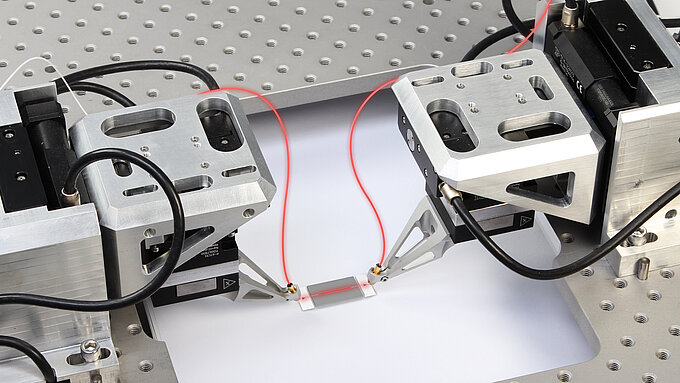

We ran this new technology through real photonics signal data simulation to quantitatively characterize alignment times referenced against current state-of-the-art methods. And the results were dramatic: the simulations under one scenario of typical alignment conditions resulted in multiple orders of magnitude improvement in first signal finding. We also carried out multiple tests, first with high-speed piezo mechanisms in free space laser coupling and close fiber to photonic element coupling with outstanding results.

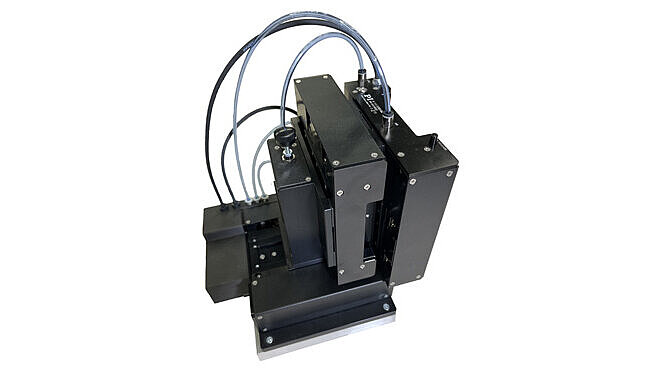

Later, we adapted the lessons learned in the piezo world to larger, multi-axis air-bearing motion systems in single- and dual-sided alignment applications.

The outcomes exceeded our expectations and have the potential to revolutionize the industry.

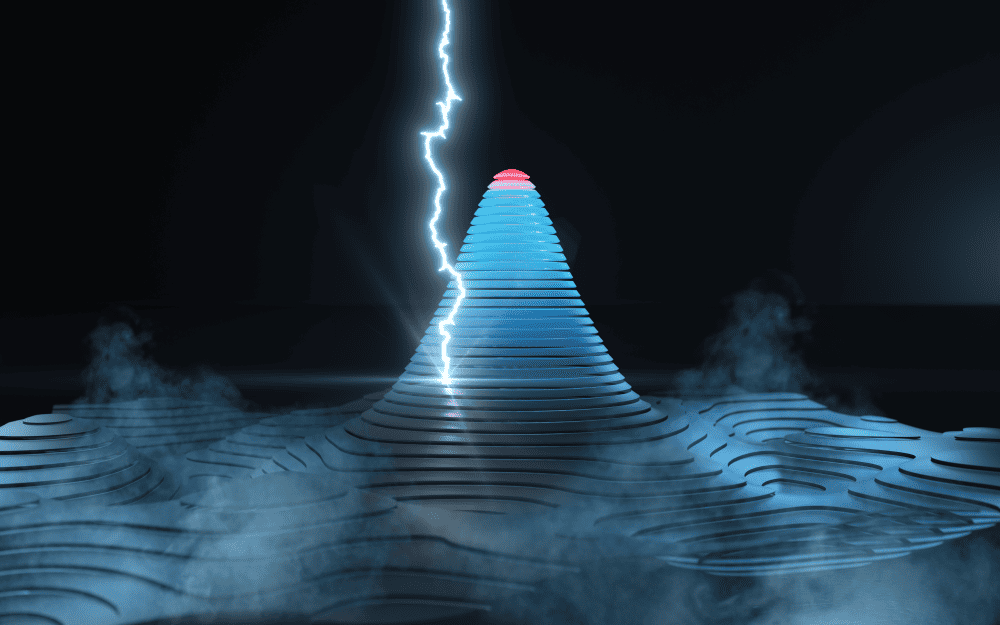

In some cases, we captured data that would perform the signal finding at such high speed it was surpassing human reaction times. The alignments were done lightning-fast, and that’s why we call this new technology PILightning.

The PILightning model is a quantum leap forward. It promises to improve alignment time by orders of magnitude – orders of magnitude faster alignment! It's outpacing any other technique currently used for automated photonics alignment in the market. We look forward to its implementation in Silicon Photonics Test & Assembly solutions.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy