Linear air bearings and air bearing stages are essential components in many high-precision manufacturing, testing, and measurement applications. They are designed to provide smooth, accurate, and repeatable linear motion with zero friction and excellent guiding accuracy (straightness, flatness, pitch, yaw, and roll), making them ideal for a wide range of applications where precision is of utmost importance. PI USA is a premium supplier of a line of in-house designed and manufactured linear air bearing systems for precision motion, metrology, and automation applications.

PI’s linear air bearings are available as passive linear slides and motorized for computer programmable precision motion. These motorized stages use ironless cog-free 3-phase linear motors or compact voice coil motors, integral optical linear encoders, and non-contact fully preloaded air bearings. Some models come with a choice of sine/cosine, A/B, and absolute BISS encoders.

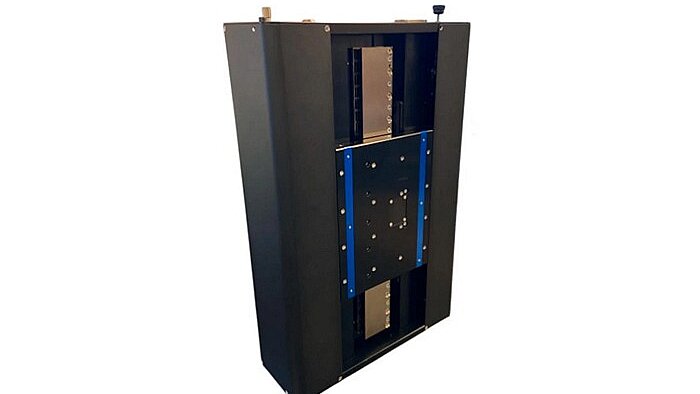

High Performance Motion Controllers to Operate Air Bearing Stages

PI also provides high performance controllers to control our air bearing stages. They feature state-of-the-art ACS SPiiPlusEC motion control modules and an EtherCAT® master and include ServoBoost™ for up to eight axes of motion. ServoBoost™ provides better, more consistent servo performance that is insensitive to noise or (load) changes in the system. The controllers can also automatically shut down the motion when an air pressure drop is sensed.

These stages use ironless cog-free 3-phase linear motors or voice coil motors, integral optical linear encoders and non-contact fully preloaded air bearings. Some models come with a choice of sine/cosine, A/B and absolute BISS encoders.

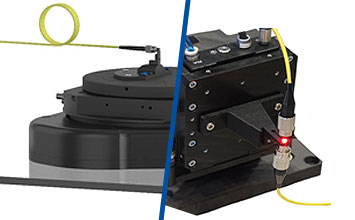

A-142 Mini Voice Coil Linear Slide

Air Bearings, Frictionless, Fast

- 10mm travel

- 3kg load

- 5nm encoder, 0.1µm straightness

- 75x80mm table; 27mm height

- 450mm/sec, 2g acceleration

- 20N push/pull force

A-143 Compact Air Bearing Stage

Ideal for Photonics Alignment

- 25mm travel

- 4kg load

- 1nm absolute sensor

- 75x85mm table; 40mm height

- 3.9m/sec max. velocity

- 1g max. acceleration

A-141 Miniature Air Bearing Stage

Ultra-Compact Air Bearing Stage

- 40mm travel

- 3.5kg load

- 20nm resolution

- 57x83mm table; 38mm height

- 0.25m/sec max. velocity

- 0.35g max. acceleration

A-110 PIglide Air Bearing Stage

Affordable Design, Travel to 16”

- 2/4/8/12/16” travel

- 10kg load

- 1nm resolution, abs/enc option

- 160x200mm table; 60mm height

- 1m/sec max. velocity

- 2g max. acceleration

A-121 PIglide Air Bearing Stage

Travel to 14”

- 2/4/6/10/14” travel

- 10kg load

- 1nm resolution, abs/enc option

- 115x115mm table; 60mm height

- 1m/sec max. velocity

- 2g max. acceleration

A-123 PIglide Air Bearing Stage

Large, Travel to 30”

- 2/4/6/10/14/20/30” travel

- 10kg load

- 1nm resolution, abs/enc option

- 210x210mm table; 85mm height

- 1m/sec max. velocity

- 3g max. acceleration

A-131 Voice Coil Positioner

For Fast Scanning/Autofocus

- 1” travel

- Optional bellows

- 1nm resolution

- 8g max. acceleration

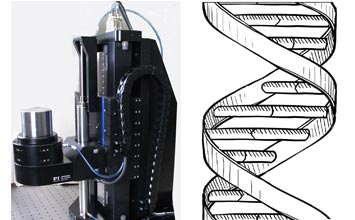

Z-Stages, Counterbalanced

Custom Examples

- Air, spring, mechanical, and magnetic counterbalance options

- Custom bridge and gantry designs

A-123.Z Vertical Air Bearing Stage

Pneumatic Counterbalance

- 50, 100, 150mm motion

- 3-Phase linear motor

- Adjustable Z-counterbalance

- 10kg max. vertical load

- Linear encoder

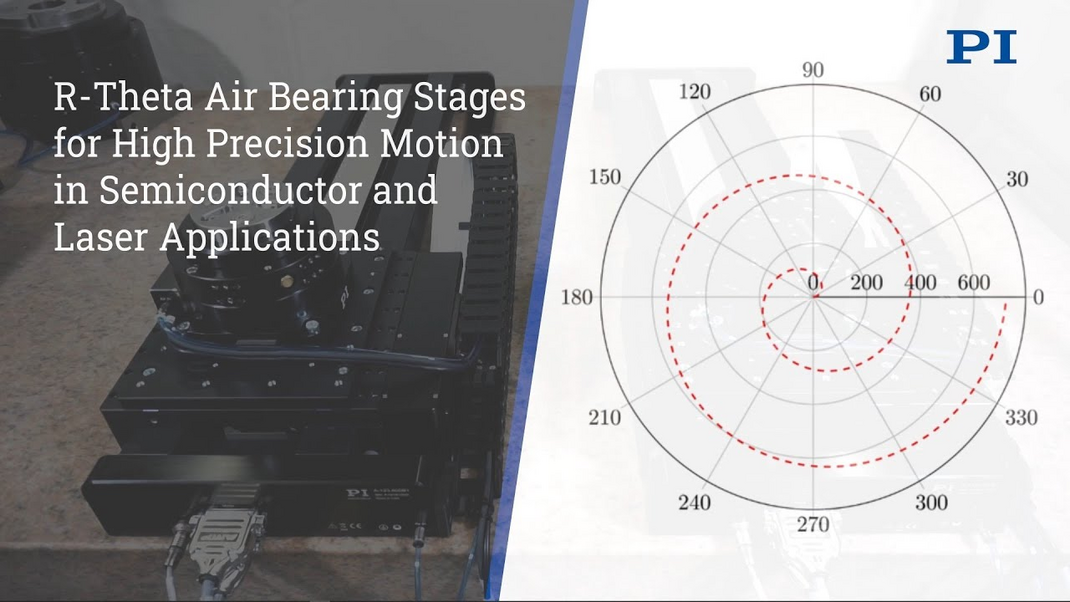

5-Axis Air Bearing Wafer Stage

Watch Video

This 5-axis stage is based on the A-311, planar XY stage and the A-523, 3-Axis Z, Theta-X, Theta-Y stage. Applications are in semiconductor and laser processing.

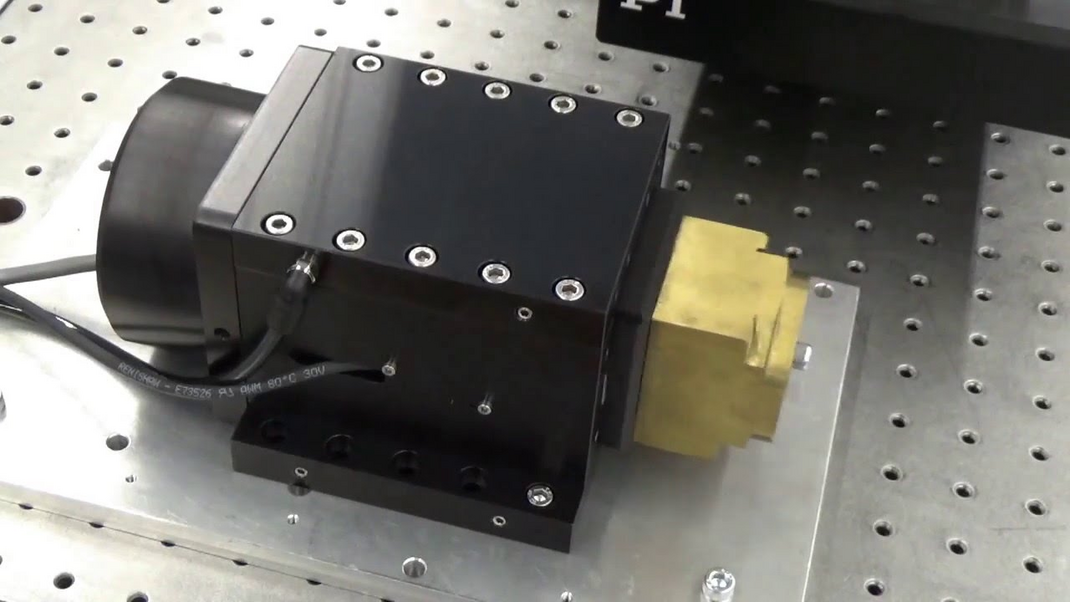

3-Axis Nanopositioning / Alignment Stage

Watch Video

This compact XYZ nanopositioning stage provides high dynamics and is ideal for fast scanning and alignment applications in 24/7 automation.

A-101 - A-109 Linear Air Bearings

Non Motorized Linear Slides

- 50 to 1000mm range

- 9 table sizes: 50x50 to 300x300mm

- 13 to 760kg vertical load

- 7.5 to 21kg lateral load

- Excellent straightness/flatness

Linear XY air bearing stages provide additional advantages compared to mechanical bearing stages. Due to one common base for the X and Y axes, torque and bending moments are eliminated and cannot influence the geometric performance (straightness, flatness) of the XY linear motion. The A-322 three motor XY-linear air bearing stage incorporates active yaw control using three motors and a flexural coupling element. In addition to linear motions in the X and Y axis, a small amount of rotational motion in theta Z is available for alignment or error correction of samples.

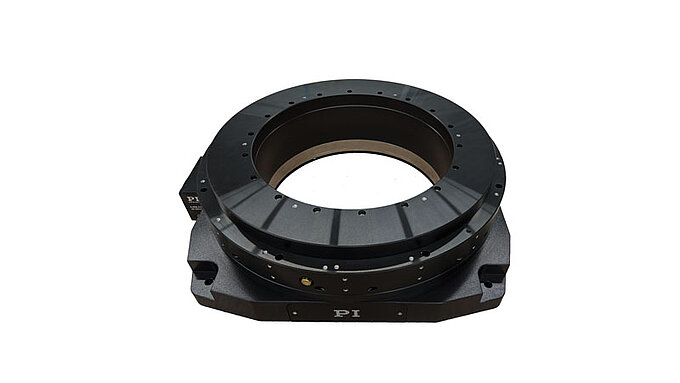

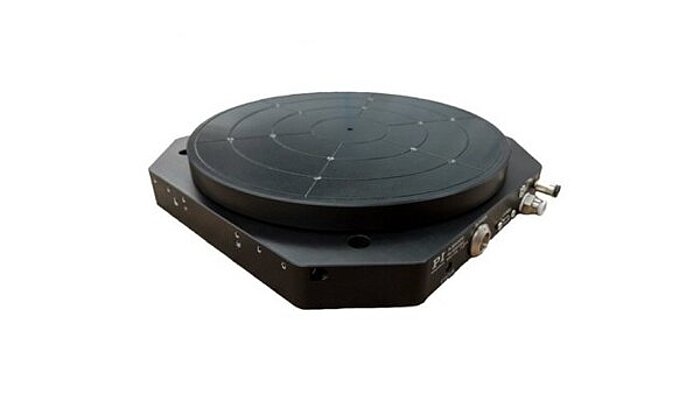

A-361 X-Y-θ Air Bearing Alignment Stage

Voice Coil Driven, Low Profile

- 5mm x 5mm x 2° Travel

- 40mm height, ø200mm

- Air Bearings & Voice Coils

- Parallel Kinematics

- Lock-down Capable

- 6-DOF Option

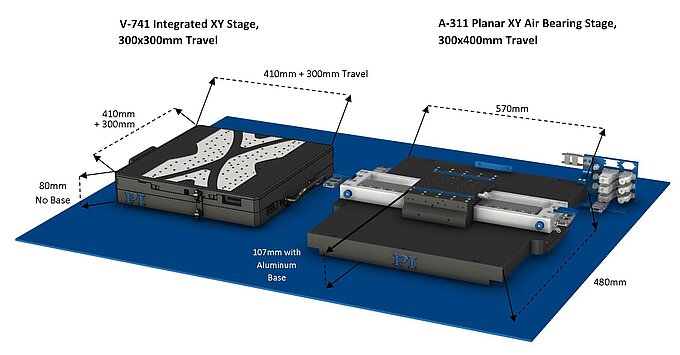

A-311 Planar Air Bearing Stage

Compact, Affordable, Al Base

- 50x50mm to 300x400mm travel

- 15kg load

- 1nm resolution

- Light weight, AL base

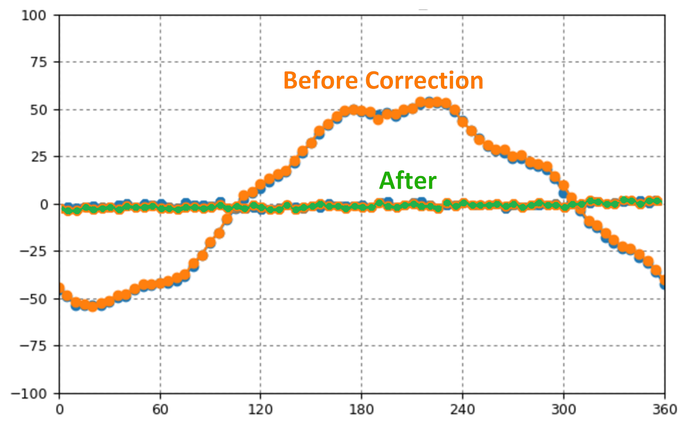

- Dynamic error mapping

- 2m/sec / 2.7g max. acceleration

A-322 Planar Air Bearing Stage

3&4-Motor Designs, Granite Base

- 3 Models: Base, Plus, Ultra

- 500x1000mm max. travel

- 15kg load

- 1nm resolution

- Active yaw control flex coupling

- Dynamic error mapping

- 1m/sec / 2g max. acceleration

PIglide XY Air Bearing Stage

Stacked XY Combinations

- Various travel ranges

- 10kg load

- 1nm resolution

- Dynamic error mapping

XYZ Laser Processing Stage

XY Air Bearing + Mechanical Z

- 100x100mm to 300x400mm XY travel

- 25mm Z-travel

- High-performance motion controller

- Optional LCM laser control module

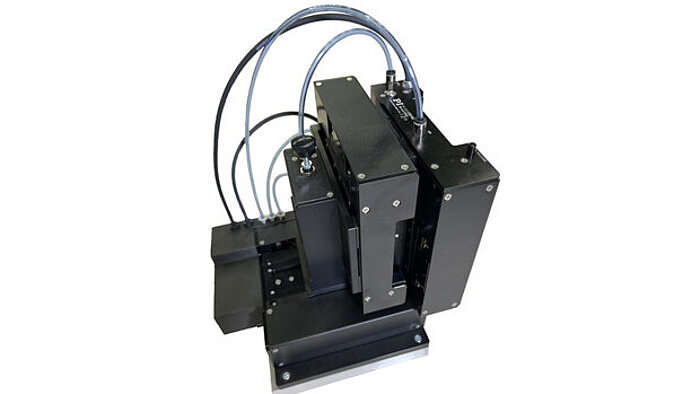

F-143 Air Bearing Multi-Axis Alignment System

High Performance Controller and Alignment Algorithms

- Zero-wear, air bearing-based, compact, photonics alignment platform

- Controller with embedded high-speed algorithms for out-of-the-box alignment and tracking

- Open-source LabVIEW code and host programming libraries for easy development

- Non-contact linear motors on all axes enabling higher-throughput and lifetime

- 25mm travel, 1nm resolution, XY and XYZ configurations

- Integrated brake and non-contact counterbalance on the vertical axis

- Optional high-performance power meter

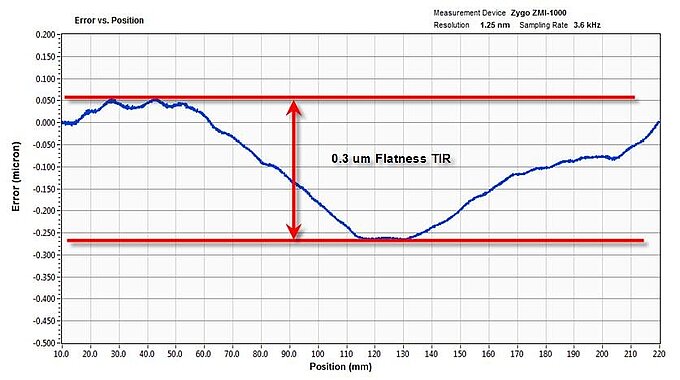

High Positioning Accuracy and Geometric Accuracy

Due to the frictionless design of linear air bearing stages and slides, they are capable of achieving very precise and repeatable linear motion, with excellent velocity regulation, making them ideal for applications where positioning accuracy is critical. For example, they are commonly used in high-precision manufacturing processes, such as in the test metrology and production of semiconductors, electronics, optical components, and medical devices. They are also used in metrology and measurement applications from optics to laser technology.

High Velocity and Fast Dynamic Response

Another important advantage of motorized linear air bearing stages is their high speed and dynamic response. The frictionless bearing design together with direct drive 3-phase motors enables fast movement and acceleration, making them ideal for applications where fast and precise motion is required. The ability to respond quickly to changes of a computer-controlled target position with minimal tracking errors makes it ideal for high-speed testing and measurement applications.

Durable and Long-Lasting

In addition to their high accuracy and speed, linear air bearing stages are also known for their durability and long service life. Since there are no components that can wear out or require maintenance, linear air bearing stages are a great match for demanding for 24/7 industrial application, where reliability is a must.

Linear air bearing stages are used in a variety of industries, including optics, photonics, electronics and semiconductors, aerospace and defense, and precision manufacturing. They provide precise and accurate linear motion control for a variety of applications, including the assembly of electronic components, semiconductor manufacturing, aerospace and defense, precision manufacturing, research and development, and biology and medical equipment.

Electronic Component Assembly

In the assembly of electronic components, such as printed circuit boards, linear air bearing stages provide precise and smooth movement during the assembly process. The frictionless linear motion of the stages helps to improve the quality and efficiency of the assembly process.

Semiconductor Manufacturing

In the semiconductor industry, rotary and linear air bearings are used in photolithography tools for the manufacturing of integrated circuits, as well as in wafer manufacturing, testing, and handling. They provide precise and smooth linear motion, ensuring that the wafers are tested accurately and efficiently, and the frictionless linear motion of the stages helps to improve the quality and efficiency of the assembly process.

Aerospace and Defense

Linear air bearings can be used in aerospace and defense test applications, such as in guidance systems, as they provide precise and smooth linear motion of optical and electronic components. They are also used in optical and instrumentation systems, even in telescopes, to provide precise and stable motion for observation and imaging. The frictionless operation of the stages helps to ensure accurate and reliable data collection.

Precision Manufacturing / Laser Machining

Another industry that massively benefits from linear air bearing stages is precision manufacturing as they provide precise and accurate linear motion control during the machining process. The smooth and frictionless motion improves the quality and throughput of laser processes as well as inspection and metrology. Linear air bearing stages with protective covers can be also used for precise and accurate linear motion control for milling, drilling, and cutting.

Research and Development

Linear air bearing stages are also widely used in scientific research and development. In the field of physics, they are used in the construction of ultra-high-precision instruments for measuring physical properties of materials, such as their coefficient of thermal expansion.