Customized Products

Competitive Edge due to Large Range and Unconventional Solutions

PI is fully at home where unconventional solutions are in demand. This is no longer limited to fields of research. Today, nanotechnology is also present in standardized industrial processes. Whether for industry or research, PI is in a position to offer solutions that far exceed the performance of "standard commercial" technology. Understanding the customers' requirements is essential in finding a creative solution.

The technological range available to PI always permits different approaches to a solution and is not limited to a single technology in advance. This often gives customers a considerable competitive edge.

Specials for Research and Development

Scientists and Development Departments Rely on PI

Be it in science or product development: Being ahead means relying on the components used. PI is used for differentiation purposes, because drive components, positioners or systems by PI can make all the difference in "state-of-the-art technology".

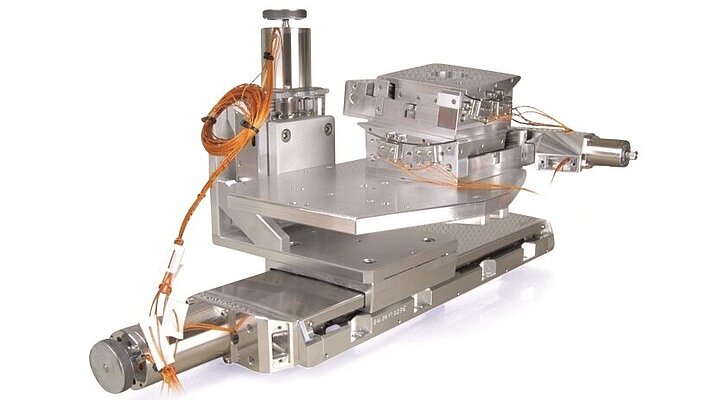

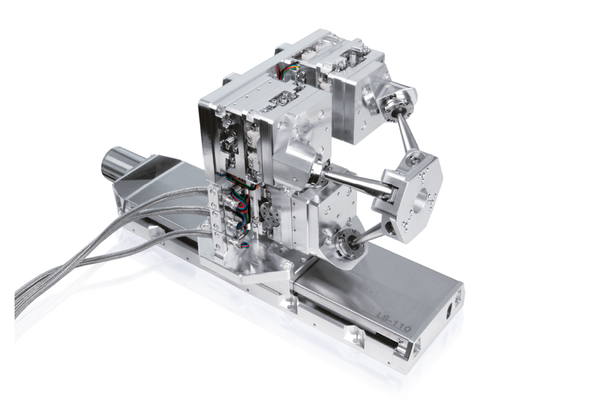

Many scientific publications cite PI systems, as they are an important requisite for successful research and development projects. Bespoke developments for public research are a daily business for PI. Extreme ambient conditions and new designs are just as common as are slight modifications for better adaptation to applications. Important fields of research are, for example, beamline instrumentation, micro systems, and nanotechnology.

And often enough, developments at universities, with PI supplying the main components, form the basis for establishing own successful and innovative companies.

- Piezo system technology at the highest level for over 40 years

- Self-developed piezomotors

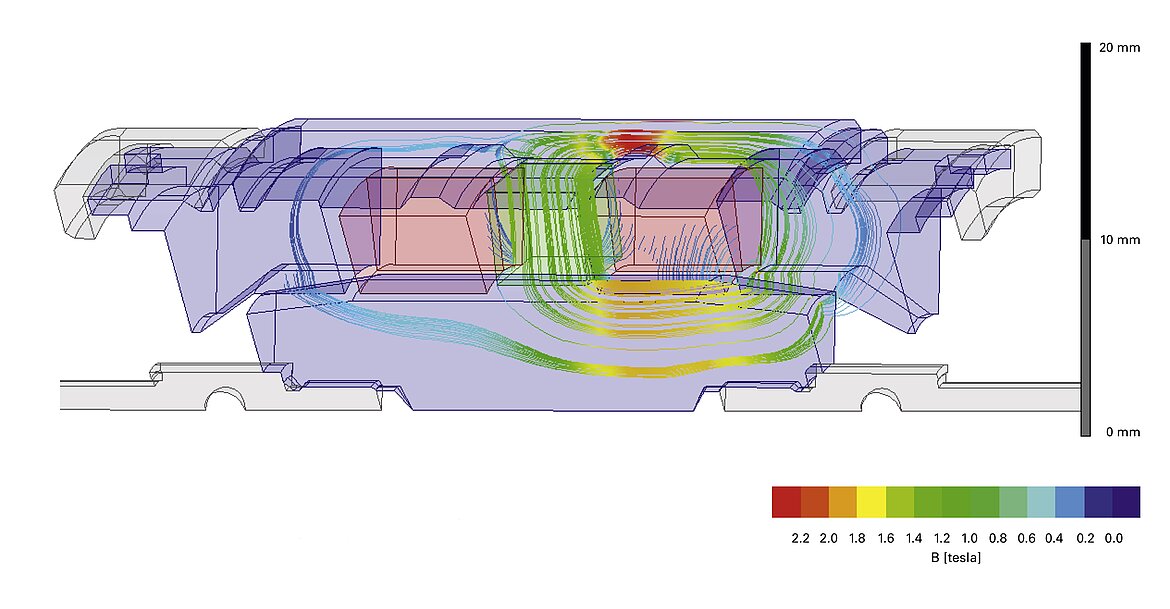

- Adaptation of magnetic direct motors, ironless and iron core

- Vacuum technology

- Own software and drivers

- Own control and control concepts

- Self-developed sensor technology for short and long travel ranges

- Highly accurate measuring technology: New and further development of measuring methods

Examples of Requirements

What Makes PI Different to Other Manufacturers

Production Capacity for Customized Products

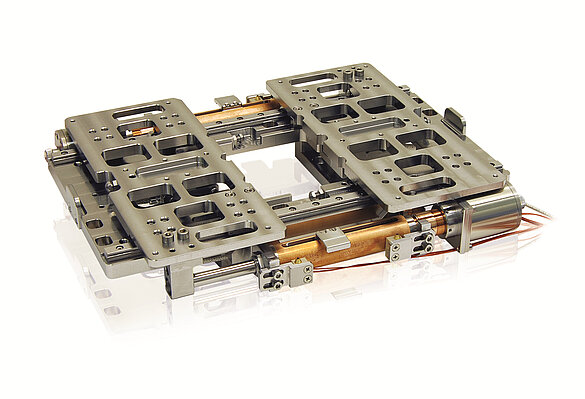

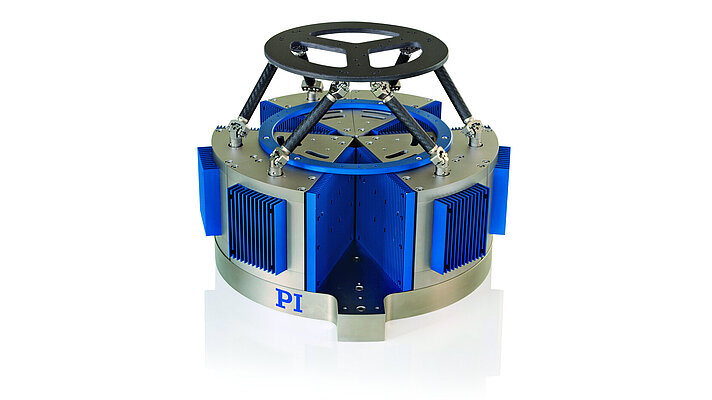

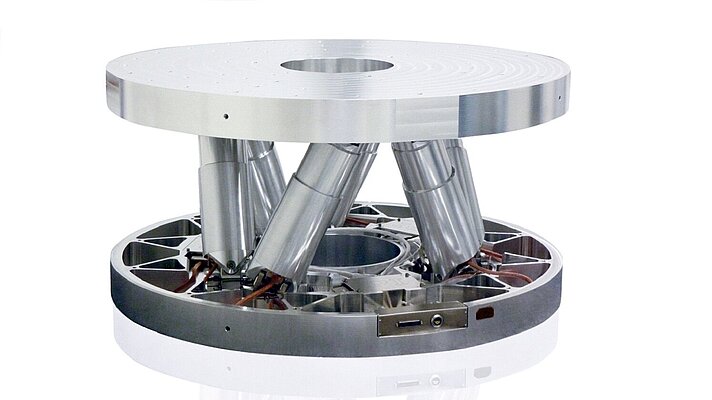

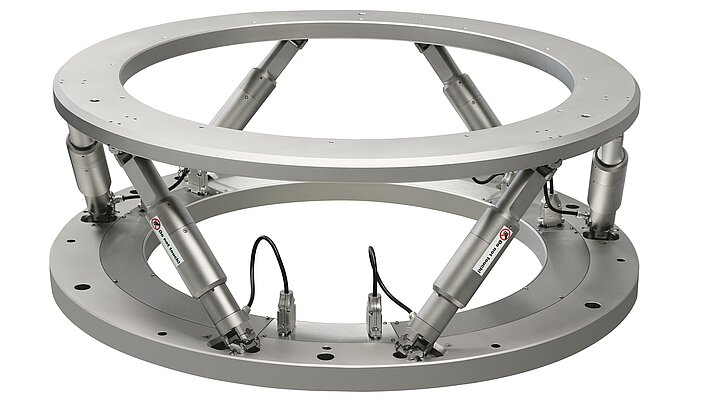

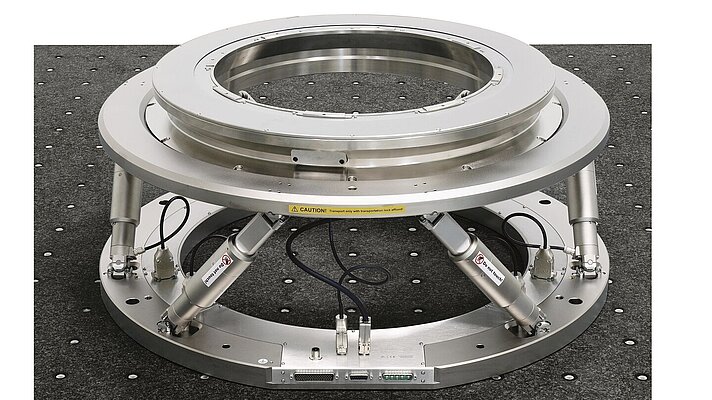

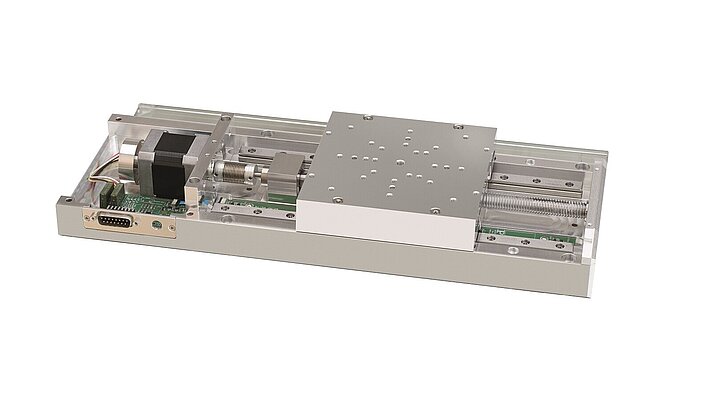

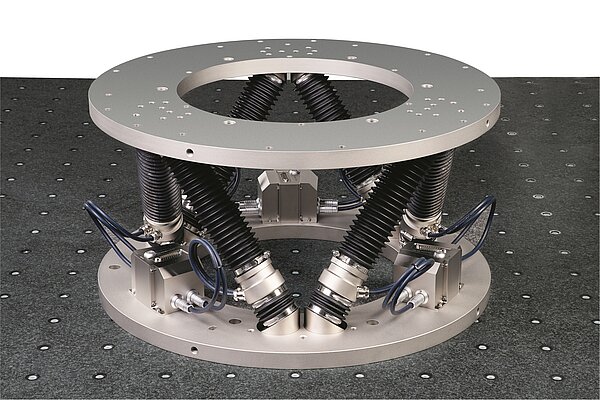

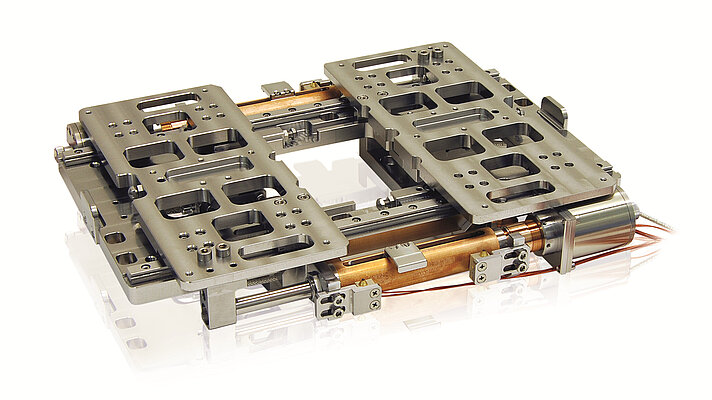

The production spectrum ranging from integrated systems, a two-ton hexapod to a 10-gram nanopositioner requires that PI has available equipment and technologies with which these systems can be manufactured, assembled, and qualified.

- 5,000 m² clean room for production

- Climate- and vibration-isolated measuring conditions

- Vacuum technology for environments to 10-10 hPa

- Metrology with traceable, calibrated external measuring equipment

- Monitoring of piezo actuator technology from material composition to final inspection

- In-house manufacturing of positioning sensors

- Heavy Duty Hall with lifting-rotating equipment

- Fractal Organization of Production Processes

The professional production, assembly and qualification has top priority, starting from the first prototype.

Ralf Fütterer, Head of the Manufacturing Fractal for Customized Products

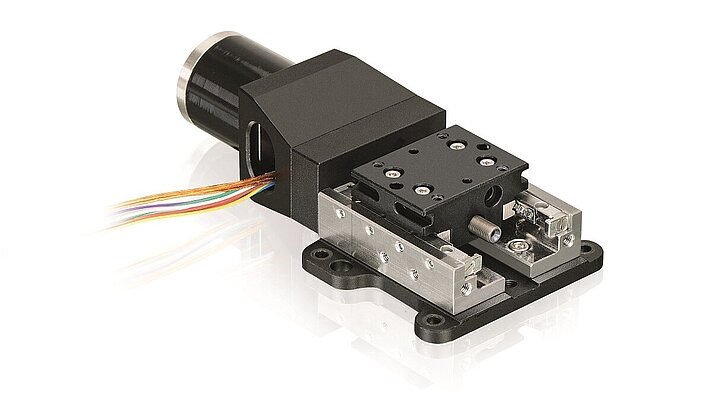

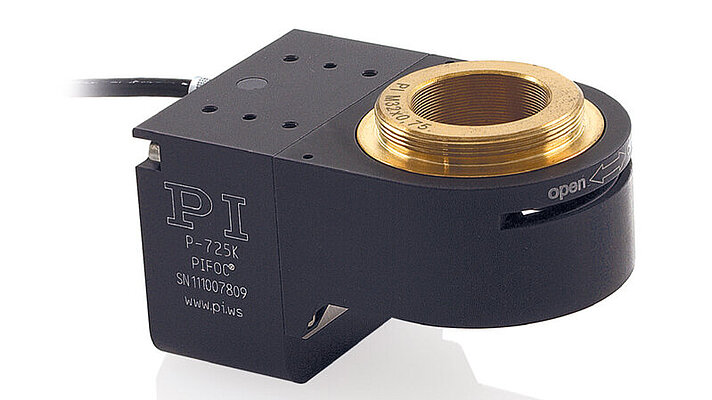

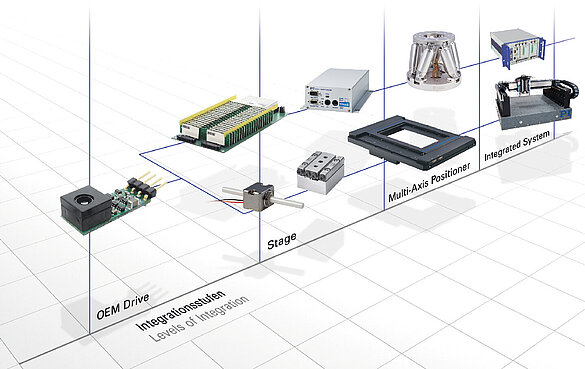

Levels of Integration

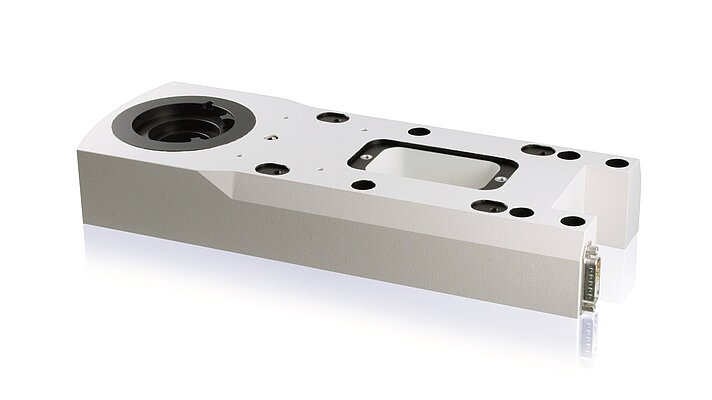

PI is a leading supplier of high-precision devices in various states of integration. Components like piezo drives, sensors and compact motion controllers can be adapted to fit into OEM machines and production equipment. Manufacturing capacity for volume production is granted. The classical positioning system provides easiest set-up and allows for individual integration into an application. Fully integrated systems offer full functionality designed according to unique market requirements.