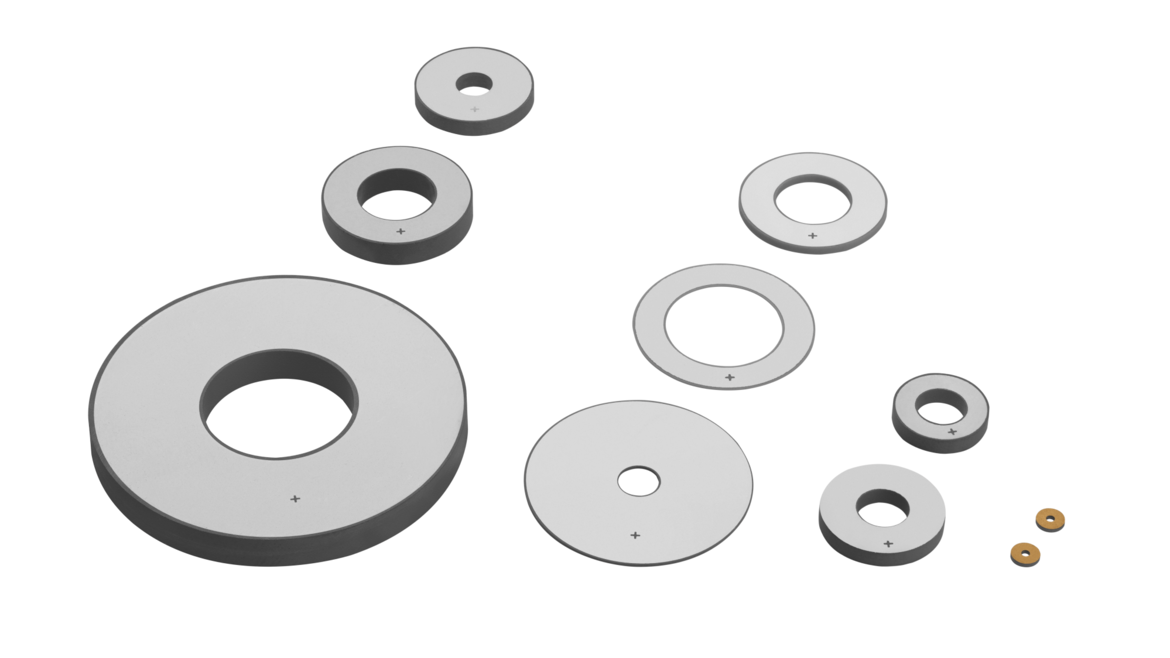

Piezoceramic Rings

Comprehensive assortment of different materials and miniaturized to large geometries

- High quality components

- Tight mechanical tolerances

- Large range of geometries (OD 1 mm to 150 mm, ID 0.2 mm to 140 mm)

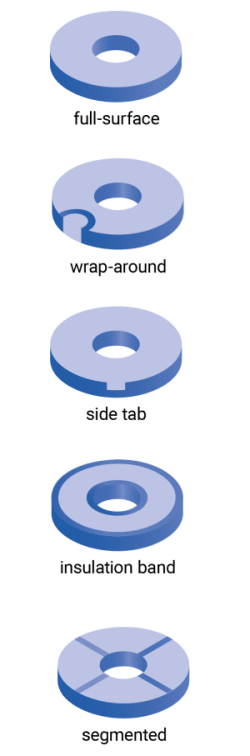

- Screen printed and sputtered electrodes available, including wrap-around contacts and structured electrodes

- Optional: ring assemblies including contacting with wires or flexible circuit boards

Piezoelectric rings are mainly used in ultrasonic applications, but they are also valid for sensor and actuator assemblies. The chosen piezoceramic material depends on the application request. They can be produced in various designs and sizes. Our technology portfolio for manufacturing piezoceramic rings enables a wide range of uses.

In industrial power ultrasound welding, drilling or cleaning applications, for example, robust piezoceramic rings made of ferroelectric hard PZT are used in a stacked configuration. On the contrary, in a mesh nebulizer, thin ferroelectric soft PZT rings are glued to a metal membrane to create tiny medication droplets for inhalation by patients with respiratory disorders.

Rings provide a decisive benefit over discs: They can be fixed by tensioning screws to achieve mechanical preload in the ceramic material.

It is also possible to further refine individual rings or to combine them to form transducer elements. Especially in assembling >> power ultrasonic transducers, piezo rings are energy-efficient, compact, and versatile components. Depending on the design, torsional movements can also be implemented in addition to longitudinal displacements.

Specifications

With more than thirty years of expertise in the development and production of piezoceramics, PI Ceramic offers end-to-end service extending from the selection of the suitable material through to the development of application-based solutions. The data of the piezo rings can be selected within specification limits. For a feasibility check, please send us your specifications or the dimensions for the piezoceramic ring.

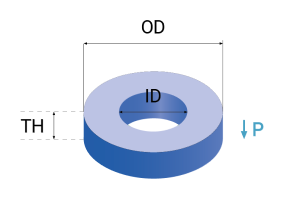

| Outer diameter OD [mm] | 1 - 150 |

| Inner diameter ID [mm] | 0.2 - 140 |

| Thickness TH [mm] | 0.15 - 30 |

| Electrodes | Thick film (Ag), thin film (Au, CuNi, Cu, NiV, etc.), electroless nickel |

| Electrode designs | Choose between various designs: full-surface, wrap-around, side tab, insulation band, segmented (see right column) |

| Polarization direction | Depending on the design of the piezo components, it is possible to achieve displacements in a longitudinal, radial, torsion, or shear direction. For more information see >> Operating Modes. |

| Material | We offer various ferroelectric soft and hard PTZ materials and lead-free alternatives. For material overview see >> here. Datasheets are available >> here. |

| Added capabilitites | Beyond advanced processing through assembly and interconnection technologies, it is also possible to develop customized, ready-to-install piezo components, such as

|

| Applications | Piezoceramic rings are well-suited for a variety of sensor and actuator applications. Examples of potential uses can be found >> here. |

Operating Modes

The use of piezoceramic rings as sensors follows the principle of the direct piezoelectric effect. Whenever a mechanical load, such as pressure or ultrasound, is exerted on the ceramics, the piezo component generates an electric signal.

When used as an actuator, on the other hand, the displacement of the piezo ring is generated when a voltage is applied. This might be a deformation induced by vibration, for example in the ultrasonic range, caused by alternating voltage. Depending on the design of the piezo components, it is possible to achieve displacements in a longitudinal, radial, torsion, or shear direction. The amount of the displacement is determined by the size of the piezo rings as well as the voltage applied.

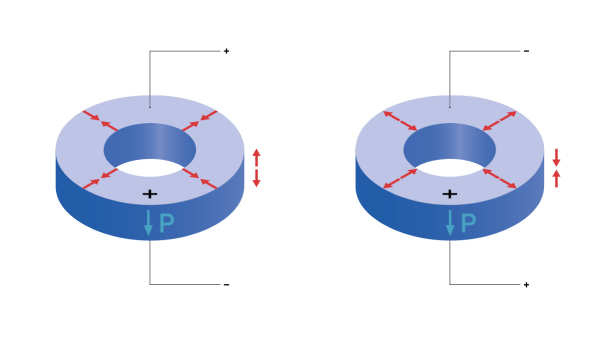

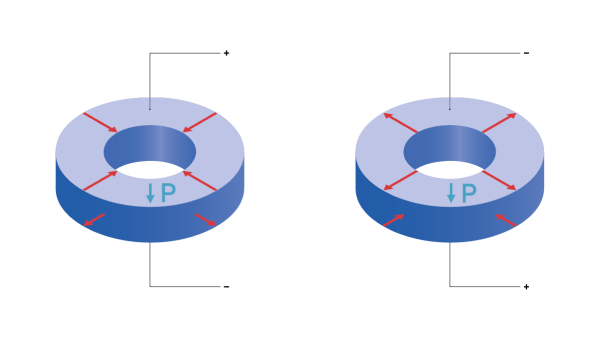

The following displacement directions occur for polarized rings with full-surface electrode:

Whenever there is a longitudinal displacement in thickness direction (d33 effect), a smaller deformation is always also generated in a radial direction (d31 effect).

To reach certain frequencies in the longitudinal vibration mode, it is necessary to change the ring thickness. For frequencies in a radial direction, their diameters have to be adjusted. The following applies for both variants: The larger they are, the smaller the frequency.

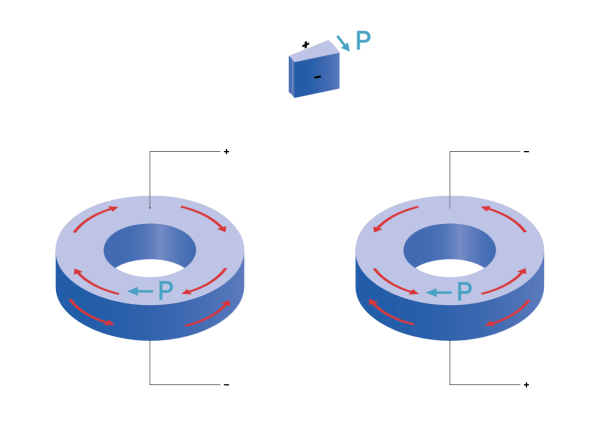

Shear rings and torsion rings require a special production path. Depending on the design, the following displacements are possible:

To achieve a torsion movement of the rings, they are subdivided into segments and the segments are polarized individually. After gluing, a shear displacement occurs in every segment, which, combined, leads to a torsion movement of the ring.

The Fields of Application of Piezoceramic Rings

Support for medical technology applications, such as:

- Mesh nebulizers

- Dental scalers

- Phacoemulsification

- Ultrasonic scalpels

- Sample preparation & cell lysis

- Ultrasonic atomization

- Material processing

- Ultrasonic cleaning

- Precision positioning

- Sensor devices

- Non-destructive testing

- Precision dosing

- Hydro acoustics

Downloads

Material Data

Lead-Free Piezoceramic Materials

User Manual A000T0047

Handling and Electrical Contacting of Piezo Components