Rotary Air Bearings, Motorized Air Bearing Rotary Tables

High Precision Rotation Stages for High Performance Motion Requirements

Rotation tables with air bearings are used when rotary motion with the highest accuracy, smoothness, and geometric performance is required, for example in optical metrology and semiconductor manufacturing. Due to the lack of friction, these high precision rotation bearings and direct-drive motorized rotary tables can achieve angular resolution in the sub-microradian range. PI’s air bearing design and manufacturing group provides hundreds of man years of design experience along with the manufacturing and test equipment to produce high quality rotary tables with the tightest tolerances.

Rotary air bearings (air bearing spindles) are friction free, and all of PI’s motorized air bearing rotation stages employ closed-loop, non-contact 3-phase direct-drive torque motors, and optical high-resolution rotary encoders for ultra-reliable maintenance-free operation with basically unlimited service life.

Absolute angle-measuring feedback sensors are available to provide closed-loop control with single digit microradian bi-directional repeatability. Direct-drive rotary air bearing tables also provide better eccentricity, flatness, and minimized wobble compared to rotary stages based on mechanical bearings. The friction-free design allows for high angular velocity without vibrations and noise.

Applications of rotary air bearing spindles / motorized direct-drive rotary tables include indexing, metrology, optical lens testing, bio-medical engineering, runout measurements of machined parts, and fiber optics.

PI’s high-performance closed loop servo motor controllers are available to precisely control position, acceleration and velocity, with advanced algorithms. Fully integrated multi-axis motion systems with linear air bearing stages and combinations with gantry systems are also available from PI’s air bearing division.

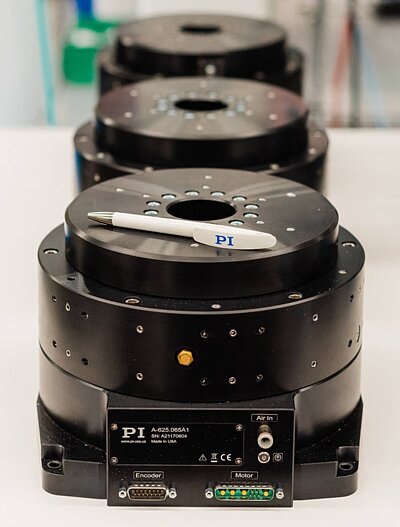

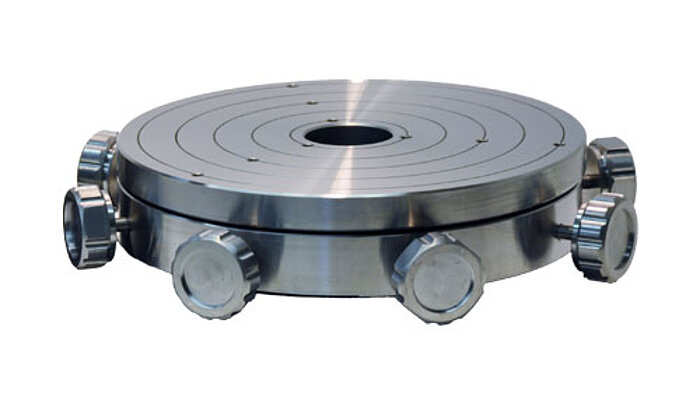

The preloaded motorized air bearing rotary tables of the A-621 - A-627 family are designed to be operated in any orientation with significant side loads up to 1200N for the largest types. The low-profile rotary table family A-635/A-637 is for horizontal use only. All PI motorized air bearing rotary stages feature high performance, low-cogging frameless and slotless torque motors, with closed-loop optical encoders. Various options can be combined to create a solution ideal for point-to-point indexing or constant velocity scanning. Applications include optical alignment, metrology, inspection, calibration, and scanning. These precision rotation stages offer superior runout, flatness, and wobble performance. Since they are completely frictionless, they exhibit no breakaway “stiction” or drag friction during operation. They are ideal for use in cleanrooms, require no maintenance or lubrication, and have unlimited life.

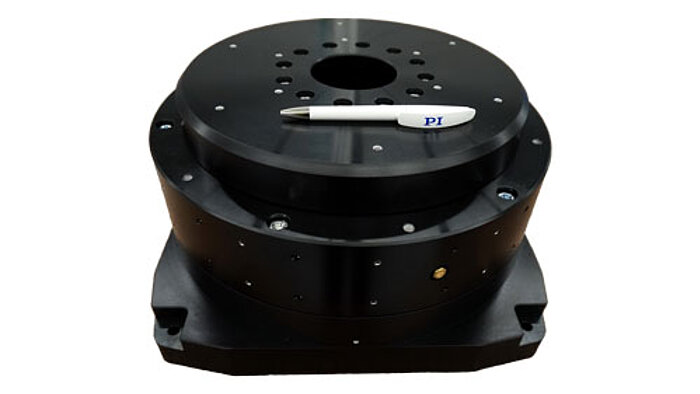

A-621 - A-627 Air Bearing Rotary Stages

Direct Drive, High Load

- 2/4/6/8/12” table diameter

- 13 to 420kg load

- 0.008µrad max. resolution

- 40 to 100nm flatness

- 500 to 2500 RPM max.

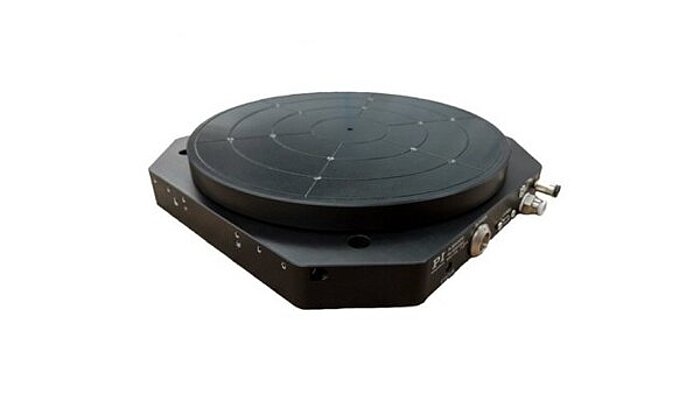

A-634 – A-638 Air Bearing Rotary Stages

Low Profile, Large Diameter

- 6/8/14” table diameter

- 20/32/60/120kg load capacity

- 0.03µrad max. resolution

- <100nm eccentricity & flatness

- 500 RPM max.

- Self-locking option at rest

A-688 Air Bearing Rotary Stage

Large Clear Aperture

- ⌀260mm clear aperture

- 77kg load capacity

- 0.0015µrad max. resolution

- 500 RPM max.

- Flatness/Eccentricity <175/300nm

- Wobble: < 1µrad

- Direct drive

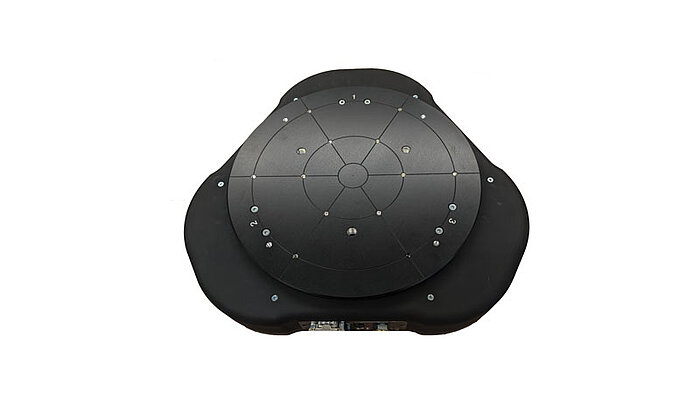

A-523 Z-Tip-Tilt Air Bearing Stage

Low Profile

- ⌀250mm table

- 8 kg load capacity

- 5mm Z-stroke, to 2° tip/tilt

- 10nm/0.06µrad incremental motion

- 1nm sensor resolution

A-361 X-Y-θ Air Bearing Alignment Stage

Voice Coil Driven, Low Profile

- 5mm x 5mm x 2° Travel

- 40mm height, ø200mm

- Air Bearings & Voice Coils

- Parallel Kinematics

- Lock-down Capable

- 6-DOF Option

These single-axis rotary air bearings and 3-axis spherical rotary air bearings come without motor but can be customized and encoder options are available for the single axis bearings. A manual X-Z-Tip-Tilt platform is available to help with the alignment of measured parts.

A-601 – A-607 Rotary Air Bearings

Non Motorized, Encoder Options

- Ideal for optics testing

- 2/3/4/6/8/12” table diameter

- 13 to 420kg axial load

- 5 to 270kg radial load

- 75 to 300nm eccentricity

- Optional high resolution encoder

A-651 - A-657 Spherical Air Bearings

3 Degrees of Freedom

- Ideal for zero gravity simulation

- 2/3/4/6/8/10/12” sphere diameter

- 15 to 635kg load

- ±45 degrees rotation range

A-60x.MTT Manual X-Y-Tilt Platform

Add-On For Rotary Stage

- Ideal for optics testing

- 4 degrees of freedom: X, Y, θX, θY

- Manual operation

- Travel to ±3mm, ±1.25°

- 3/4/6/8/10” table diameter

- Direct mount on A-60x / A-62x

PI also provides state-of-the-art motion controllers to operate its precision rotational and linear motion systems. Based on ACS SPiiPlusEC motion control modules and an EtherCAT® master, they come with ServoBoost™ for improved servo performance, insensitive to noise or (load) changes, as shown in the video.

A-811/2/4 PIglide Motion Controller

Compact: 1, 2 & 4 Motion Axes

- Fully integrated closed-loop servo, amplifier module & power supplies

- 600W power supply

- 3-phase BLDC / voice coil / DC

- Quiet PWM drives

- Sine/cosine and BiSS-C encoders

- 10A Peak output current/axis

A-824/6/8 PIglide Motion Controller

High Power: 4, 6 & 8 Motion Axes

- Fully integrated closed-loop servo, amplifier module & power supplies

- 2000 W continuous, 3900 W peak

- 3-Phase BLDC / voice coil / DC

- Quiet PWM drives

- Sine/cosine and BiSS-C encoders

- 20A peak output current/axis

Motion Controller Adapts to Different Loads in Real Time: ServoBoost™ from ACS

Watch Video

An advanced algorithm called ServoBoost™ in ACS motion controllers automatically adapts the servo settings to load changes in real time.