PI Webinars - Moving Forward, Together

PI engineers collaborate with customers, sharing experience, learnings, victories and failures. Our engineers also share their knowledge through webinars. Here are some that may be of interest to you.

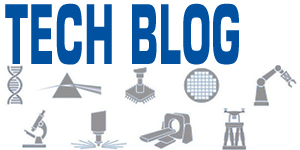

Latest Advances in Laser Drilling of VIA holes

This webinar covers the latest advances in laser drilling of VIA holes—critical for higher-bandwidth communication and compact device footprints. Presented by laser and motion control experts, it equips engineers and managers in semiconductor, photonics, optics, and medical device manufacturing with essential technical insights. Topics include common VIA materials and shapes, plus key challenges such as hole geometry and precision at high speeds.

Ubiquitous Photonics, Universal Challenges, New Solutions for Economic Production at Scale

Photonic technologies and sensors are transforming daily life, from autonomous car navigation to wearable health monitors and structural safety sensors in aviation, infrastructure, and renewable energy. As demand surges, manufacturing and testing these devices remain challenging. This has driven the rise of an ecosystem including advanced metrology, autonomous micro-robotics, and skilled integrators, to meet growing demand and productivity goals in photonic technology and sensor manufacturing.

When Precision Matters: A Deep Dive into Air Bearing Motion Systems

In today's increasingly sophisticated world of test and production machinery, the demand for precision, reliability, and efficiency is paramount. Traditional motion systems, including roller and ball bearings, have paved the way for various advancements, but limitations exist. Enter: Air Bearing Motion Systems. In this webinar, we embark on an insightful journey into the world of air bearing motion systems, specifically tailored for machine builders.

Good News: Photonics is Mainstream. Now We Must Scale.

New application fields have propelled photonics into a three-orders-of-magnitude ramp-up that we, together, must navigate over the next few years. Riding this tsunami of change requires an ecosystem of interlocking capabilities. Toolmakers, integrators, contract manufacturers, consortia, research institutions, and regulators must all contribute. The challenge boils down to three things: automation, innovation, and cooperation.

Unleashing the Power of Photonics

Join a tech talk on enabling technologies for the photonics industry, featuring speakers from MPI, EPIC, CITC, Transcelestial, and PI. Photonics is opening new opportunities across all sectors, driving innovation in areas ranging from consumer electronics and communications to health care, energy, and advanced manufacturing. It is also a key enabler in cutting-edge fields such as quantum computing.

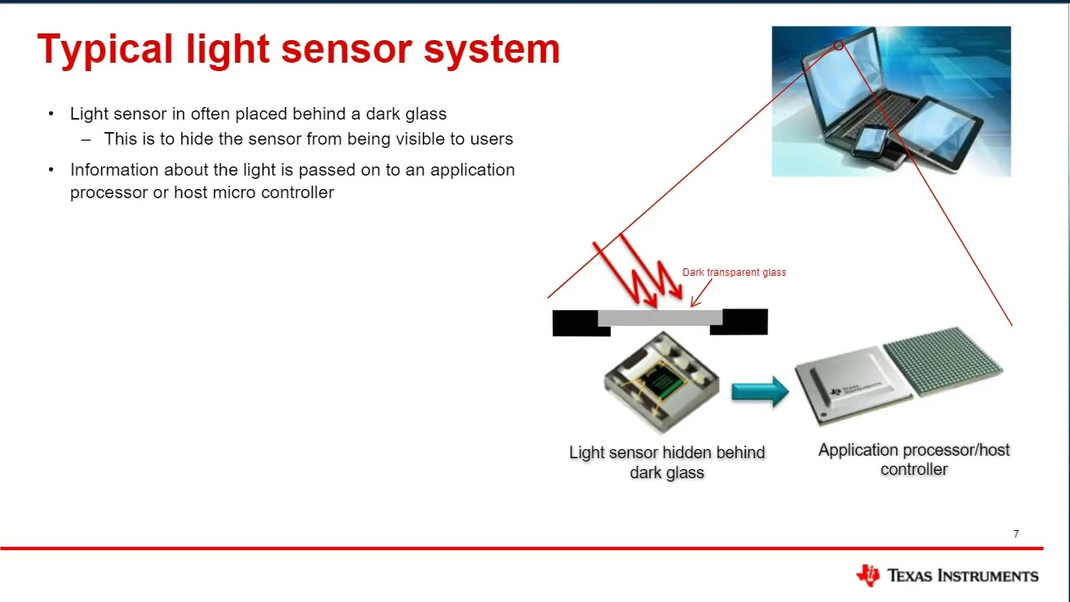

Getting Optical Sensing Right, from Autonomous Vehicles to Automation Systems

Optical sensors, which convert incident light rays into electrical signals, are used in applications requiring non-contact sensing to detect the position of objects or count parts. These sensors measure the amount of light and convert it into a form that can be read by an integrated measuring device. Optical sensors are finding home in many non-contact sensing uses, from autonomous mobile equipment such as cars and robots to automation systems. This webinar will explore where optical sensing is as a technology and what advances we can expect in the foreseeable future.

Increasing Output and Reducing Costs in Test and Assembly of Optical Components

The need to scale for production volumes 1,000 times higher than today and to adapt to ever shorter innovation cycles makes efficient implementation of alignment mandatory. In this joint webinar with Averna, hear from the quality and precision experts on optimized machine architecture and automated solutions enabled by active alignment as core technology.

Generating Precise A/B Quadrature Signals from Motion Platforms without Inherent Digital Feedback

Digital Quadrature Encoders have become a de facto standard for precision automation systems used in laser materials processing, additive manufacturing and test/inspection. In this talk, we’ll discuss how encoder technologies effect process performance while presenting on recent work that will allow the next generation of tools to use Absolute Encoders, Analog Encoders or no encoders while still enabling tool process synchronization with devices that require Digital Quadrature Encoder Signals.

Tech Talks - Enabling the Technologies for Semicon

Join a tech talk on enabling technologies for the semiconductor industry with speakers from ASML, FormFactor, Carl Zeiss SMT, ACS, and PI. Semiconductor technology drives progress in GPUs, data storage, signal processing, and opto-electronics, enabling advances such as artificial intelligence, 6G, IoT, and autonomous mobility. This webinar highlights market trends and technological developments to meet the growing demands of manufacturers and end users

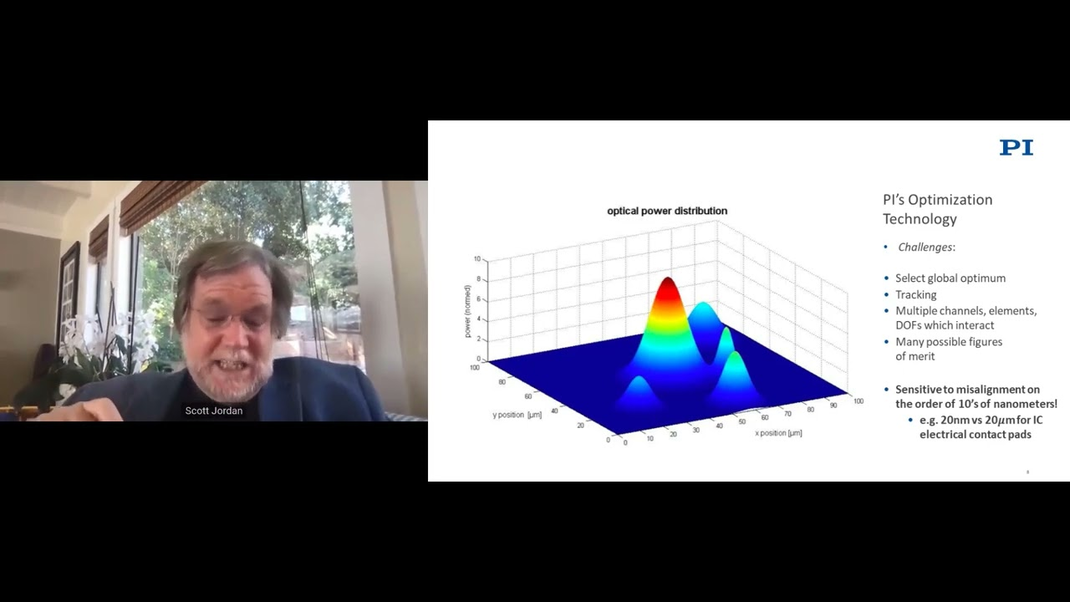

Expanding Implementation of Fast Optimization Technology for Photonics, Optics, and Quantum Manufacturing Applications

Fast alignment technology was first introduced to speed up silicon photonic wafer probing and package assembling. The technology quickly achieved industry-standard status. Now, fields of application have expanded from its original use in piezo nanopositioners to implementation into modular stacked-axis motion assemblies, gantry (Cartesian robot) configurations, and hexapod microrobots. Increased implementation significantly reduces cost for the test and assembly of large-format substrates such as circuit boards, coupons, trays, and carriers.

Stage Design for Demanding and High Performance Automation Applications

When selecting the best suited motorized positioning stages for today's demanding applications, a thorough understanding of how the individual components used in a given stage design can enhance or limit achievable performance. Motion controller design and architecture is another critical aspect on the overall system performance and ease of integration with 3rd party equipment. In this webinar, we will explore and contrast these individual contributors and their potential influence on the overall success of the application.

Building Value, Reducing Risk in Multi-Axis Automation Projects

Is there an easier way for machine builders to de-risk the process of building multi axis motion control systems? How can motion equipment supplier help in this, by offering more than just a catalog of stage data sheets? PI will discuss a platform development which addresses some of concerns that machine builders have, when selecting motion control equipment for integration into their solutions.

Optimize Your Multi-Axis Motion Process

How to choose the right multi-axis architecture for your optimization and alignment application - Parallel Kinematics (Hexapods) vs Serially Stacked Stages? Learn how to best solve your application-specific needs multi-axis precision positioning and motion applications in fields such as precision assembly, photonics, optics, metrology. The webinar introduces the possible motion systems and highlights its mechatronic modules that determine application results.

Tech Talks - Let's Shape the Future of Laser Materials Processing

Join a tech talk on enabling technologies for the laser materials processing industry with speakers from Coherent, Laser nanoFab, SCANLAB, DMC, Fraunhofer IWS, and PI. Modern lasers and processing systems are essential for advanced industries, lowering costs while boosting flexibility, precision, and throughput. This webinar brings together experts to discuss the latest market trends, applications, and technologies shaping the future of materials processing.

Advanced Motion and Positioning Techniques for Laser Materials Processing and Photonics Components Test & Production

This two-part webinar presents state-of-the-art motion control and positioning solutions for ultra-fast laser material processing of transparent materials and for test and production of photonics components and SiP circuits. New motion control and alignment algorithms, advanced software, system architecture, serial and parallel kinematics, and precision mechanics are covered. The webinar is useful for engineers and system architects and integrators working in the laser processing, optics, and photonics industries. Our focus is on minimizing total cost of ownership and rapid implementation.

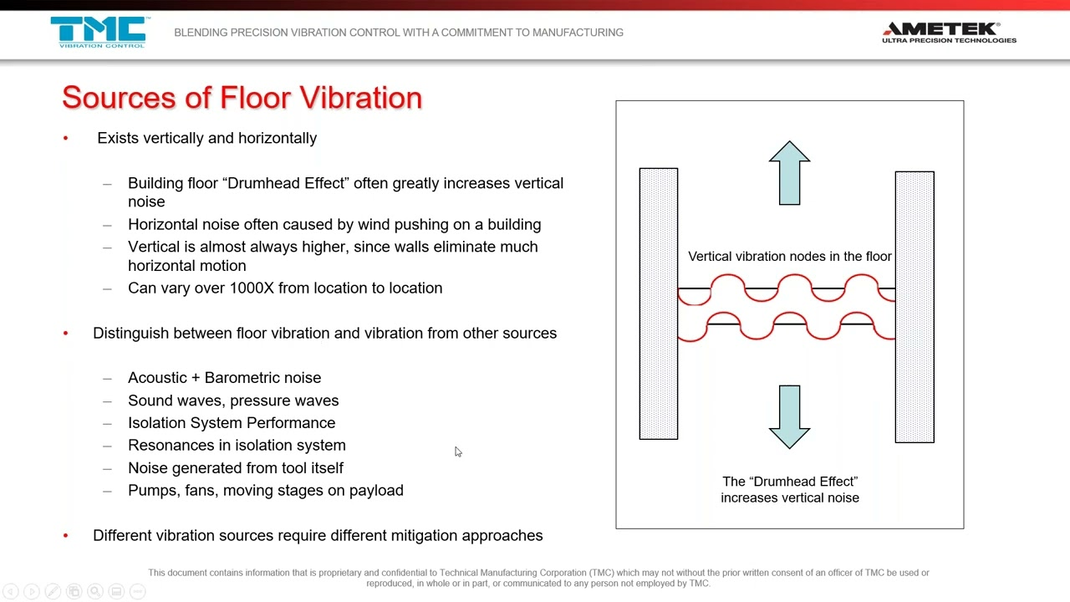

Nanopositioning and Vibration Mitigation Technologies for Advanced Microscopy Applications

This webinar is a joint presentation between Ametek TMC and PI (Physik Instrumente). Piezoelectric actuators (transducers) are precision ceramic actuators which convert electrical energy directly into linear motion with high speed, force and virtually unlimited resolution. In this webinar, we will discuss their application to advanced microscopy in which piezos are used for nanopositioning of samples, focusing of microscopes, and mitigation of floor vibration. All these elements are required to achieve optimal resolution.

Improving Production Economics in Photonics Test/Assembly and Ultrafast Laser Materials Processing of Transparent Materials

This webinar presents the latest advancements in precision motion control techniques, system architecture, software, algorithms, hardware, and mechanisms for system designers in the laser processing, optics, and photonics industries. The focus is on rapid implementation and minimizing total cost of ownership.

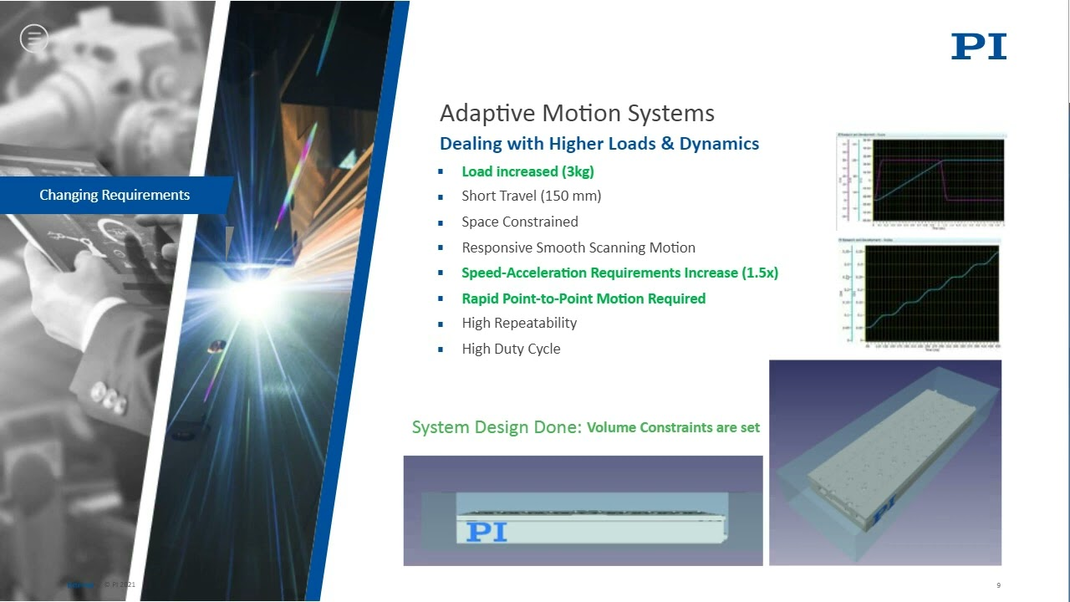

Adaptive Machines for Precision Automation

Novel designs, from lightweight single axis, direct drive systems to multi-axis gantry machines to solve the gamut of precision motion and automation tasks are discussed. The advantages of adaptive machines are multifold, offering more efficient and lower cost/better optimized system builds while also simplifying downstream service and support. In research and application labs, these tools can support both near term and longer-term aspirational research goals with flexibility to accommodate collaborative work along derivative lines of inquiry. Hear us discuss how these modular systems are designed, developed in collaboration with our motion partners, and the proprietary technologies and expertise on which they rely.

Intelligent Motion Systems Based on Fast Optimization Algorithms and Hexapod 6-Axis Mechanisms

Hexapods solve complex multi-axis precision positioning applications. Join us for a discussion on the basic principles of hexapod controls and software and compare the parallel setup with a serial kinematics setup, illustrating its advantages and limitations and looking into features such as stroke, workspace, precision, size, stiffness, dynamics, and its randomized pivot point functionality. Intelligent algorithms and motion systems used for optimization of throughput in applications — such as active alignment of photonics circuits, optics, detectors, and emitters — will also be discussed in relation to the principles of PI’s fast alignment algorithms and the achievable performance with the latest positioning hardware.

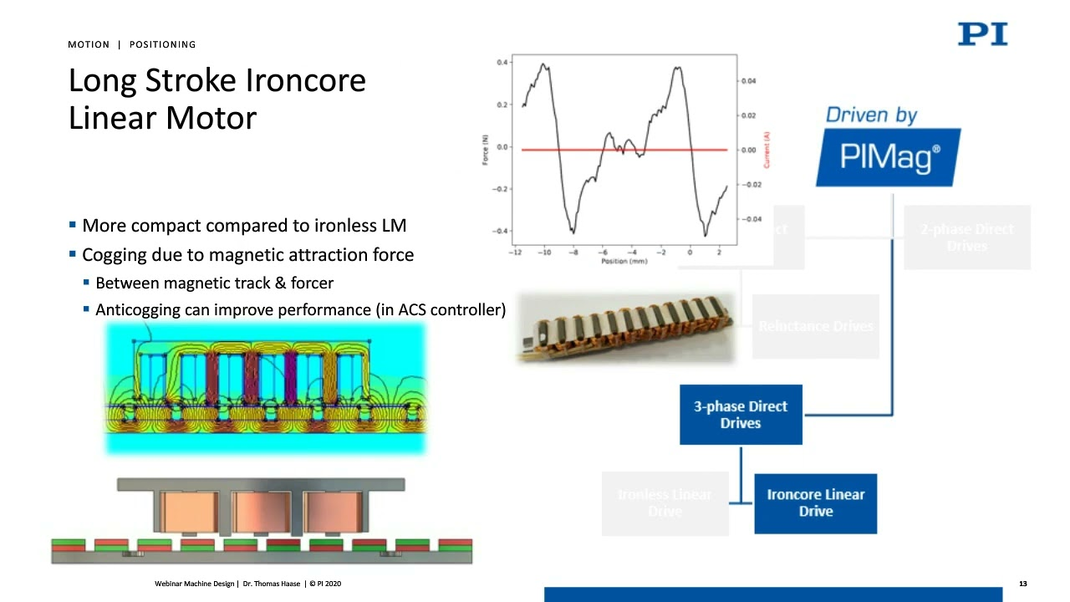

Custom Direct Drive Motors for Motion Control and Precision Positioning Applications

Recent advancements in electormagnetic motors, especially when it comes to performance and miniaturization, allow instrumentation equipment and precision automation solution engineers to design better, faster systems in fields such as medical engineering, semiconductor test/manufacture, photonics, and micro-mechanical assembly. Learn about different motor and drive concepts, advancements, limitations, and boundaries of each type, and most importantly, what type to choose when and how they compare to the latest piezoelectric motor designs.

Piezo Mechanisms - Motors, Actuators, Transducers

Differences, Advantages, Applications - When to use What?

The demand for miniaturization, higher precision, and speed keeps pushing manufacturers to look for better drive technologies. Piezoelectric actuators and motors have provided the answer to these challenges in fields from biotechnology to aerospace – however there is no “One-size-fits-all” solution. Join PI’s piezo experts as they discuss how these compact mechatronic systems can be employed to solve critical motion and precision positioning problems and how to avoid pitfalls.

Advances in Precision Motion Control for Electro-Optical Manufacturing and Laser Materials Processing

Focusing on high-throughput/high-yield positioning and micro-robotic solutions for leading-edge manufacturing, this webinar presents the latest advances in software, control algorithms and motion systems hardware available to design engineers and scientists in the laser processing, optics and photonics industry

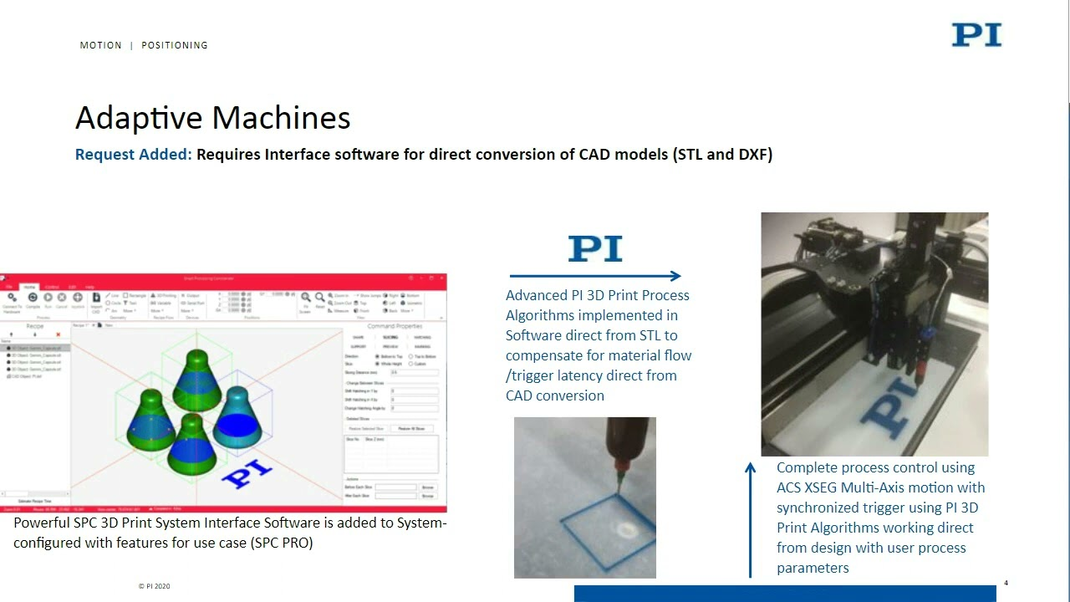

Adaptive Machines

Precision automation platforms supporting next-gen, flexible, multi-purpose tools for applications such as additive manufacturing, laser machining, and scanning.

The ability to address multiple processes in a single, flexible, and scalable automation platform is key to adaptive machines. The advantages of adaptive machines are multifold, offering more efficient and lower cost/better optimized system builds while also simplifying downstream service and support. In research and application labs, these tools can support both near term and longer term aspirational research goals with flexibility to accommodate collaborative work along derivative lines of inquiry.

Photonic Integrated Circuits - Assembly & Packaging

A Modular Concept Towards a Fully Automated Process

A collaboration between Physik Instrumente (PI) and the TEGEMA B.V. has provided a decisive breakthrough in assembly and packaging technology. The modular Photonic Packaging Platform from TEGEMA, with PI's proven super-fast coupling system, achieves complete assembly cycle times of less than 30 seconds, an important step towards readiness for series production. With a small footprint!

- Part one: Modular Machine Plat Form Enables Breakthrough In Photonics Assembly Speed

- Part two: Inside the Solution: Intelligent Micro-Robotics for High Throughput Photonics Manufacturing Automation

Intelligent Positioning in High Throughput Photonics Manufacturing Automation

The key in Silicon Photonics and other precision optical fieldsis leveraging optical physics to separate dependence on position commandability. A universal implementation is now commercially available and fab-proven. Process cost reductions of 99% are seen. This technology and its applications is discussed, and a live demonstration of parallel array I/O alignment is offered.

Piezoelectric Transducers for Liquid Handling, IVD, PoC, Cytometry, Array Spotting

The webinar covers applications in IVD, PoC, Cytometry, Array Spotting or Lab Automation. Piezoelectric transducers enables devices in IVD tests to provide high speed and handle high sample throughput. With their minimized dimensions and low energy consumption, piezo transducers are more efficient mobile systems and liquid handling systems for diagnostic devices, because of their ability to efficiently control minute sample volumes in microfluidic channels with high speed.

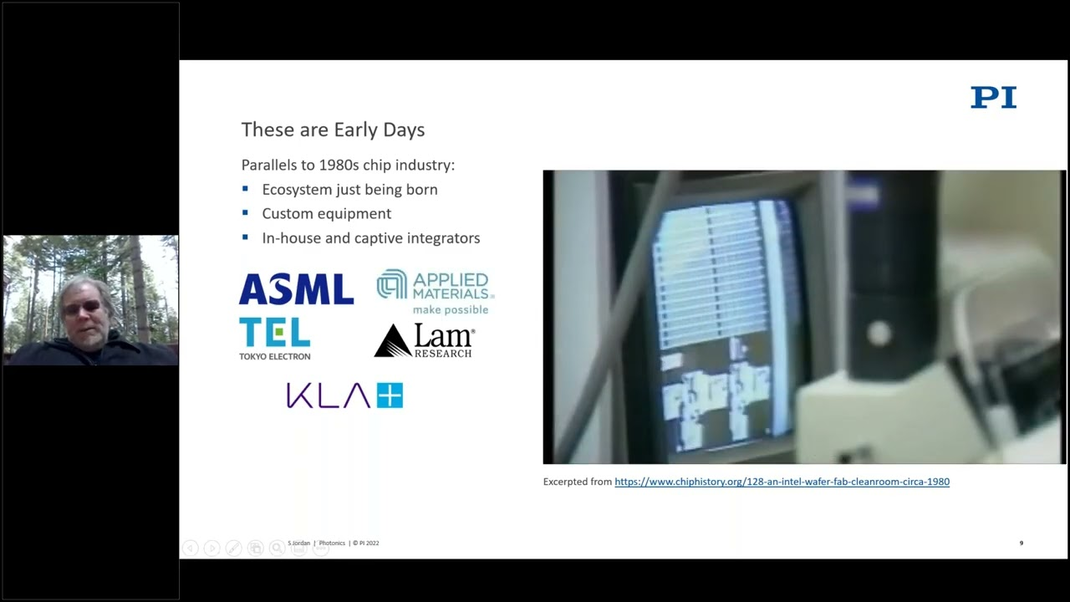

How Advances in Motion Control affect Photonics Innovation

In this webinar, we'll draw insights from the semiconductor industry's comparable explosive growth about four decades ago. This historical reference unveils three fundamental tools that any successful player must adopt and exploit for the industry to thrive during this significant shift: Innovation, Cooperation, and Automation.

Save Your Time – Get Free Advice from Our Engineers

There is no need to spend your time comparing the features, pros, and cons of all the different drive technologies and products we provide – unless you want to. Instead, talk to our engineers first.