Typical specifications are:

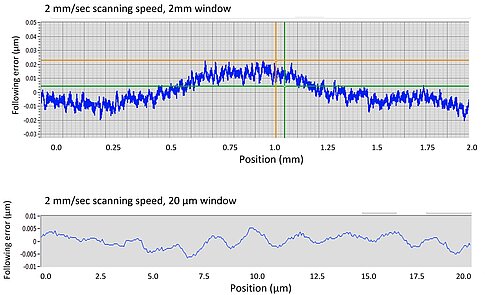

Linear: Straightness/Flatness 0.1µm/25mm, Pitch/Yaw 0.5 arc-sec/25mm

Rotary: Radial/Axial Runout 0.1µm, Wobble < 1 arc-sec

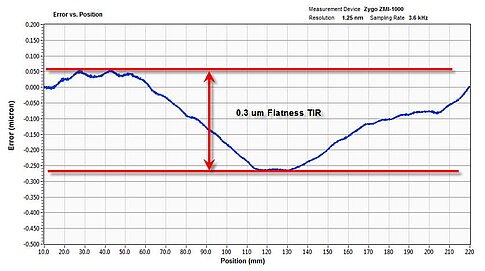

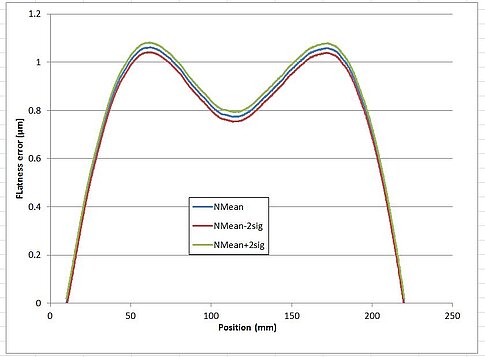

The total error motion over full travel is usually specified in “microns TIR.” TIR means Total Indicator Reading. TIR is specifying the peak-to-peak measurement of error motion. We do not assume symmetry about a zero reference. Air bearing stages can typically achieve better than 1 µm flatness and straightness TIR for every 200 mm of travel.