Customized Turn-Key Laser Solutions with Optimal Precision and Throughput

Physik Instrumente (PI) and Turner Laser Systems (TLS) collaborate to increase ROI for customers

Looking for Turn-key Laser Processing Equipment?

If you’re looking for a turn-key solution for laser processing equipment, our trusted U.S. laser integrator offers customizable and pre-designed laser and automation precision solutions. They can help you select the right components, develop the optimal process that will meet your technical, manufacturing, and business needs, and deliver them all in a production-grade machine.

The Importance of Your Integrator

In laser precision solutions, having an expert integrator as a trusted advisor can make all the difference. Your investment in advanced motion solutions and capital equipment could fall short if you did not have an expert integrator who understands both laser and automation technologies. Introducing laser technology to your product development and successfully bringing it to manufacturing can be challenging and risky. Walking alongside you, TLS collaborates with different partners to help you avoid unexpected pitfalls, often referred to as the Valley of Death, and mitigate risks that may jeopardize your entire program.

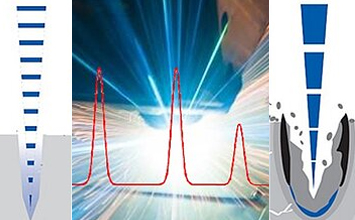

As part of PI’s commitment to your success, we form partnerships with industry experts to give you options that ensure success in projects utilizing our products. We work closely together with TLS to help our customers achieve optimal results, such as improved precision and throughput via XL SCAN. They are knowledgeable with PI’s range of precision motion and control products and are the recommended integrator for XL SCAN, which was co-developed by SCANLAB and PI’s ACS Motion Control.

How TLS and PI Work Together to Benefit You

- We work together to help you select the right components for your application.

- Components include PI’s world class precision motion solutions, advanced motion controls designed for the laser micromachining industry, the appropriate laser and beam delivery.

- TLS provides feasibility and development experiments in their laser applications laboratory using their unique methodology so that they can mitigate risks early on, manufacture your parts, and ensure you’ll get the results you need before committing to capital procurement.

- TLS provides customizable and pre-designed equipment solutions that can help save costs, time, and lower the risk of your investment.

- The collaboration between PI and TLS can mean faster time to market and higher likelihood of success as we address your technological, manufacturing, and business needs earlier on in the process.

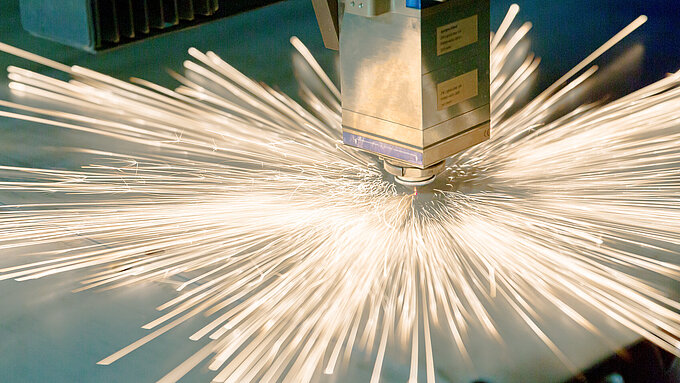

- Laser solutions are offered for micro-machining/precision process in all industries, from R&D to high-volume manufacturing, including a variety of optional automation solutions that integrate wafer handlers, robotics, conveyors, roll-to-roll, and other automated solutions.

- Applications include but not limited to laser drilling, welding, cutting, dicing, marking, or scribing.

Turner Laser Systems Applications Laboratory in California is run by a specialized team of laser physicists and engineers. This team provides you access to quality laser equipment, motion solutions, process knowledge, and automation capabilities. Here TLS crafts your solution and provides you with critical data so you can confidently and efficiently make smart capital investments.

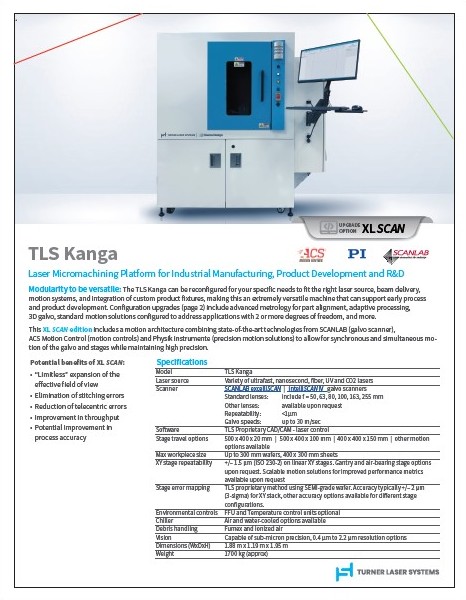

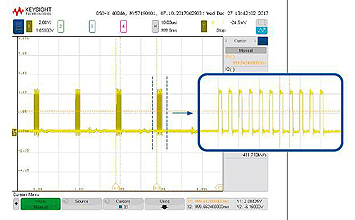

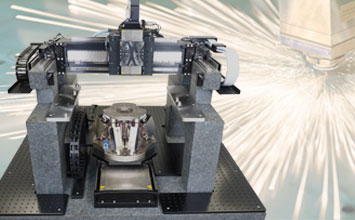

XL SCAN Set Up in TLS Applications Laboratory

Contact Turner Laser Systems for a demo if you’re interested in knowing how to maximize your precision and throughput.

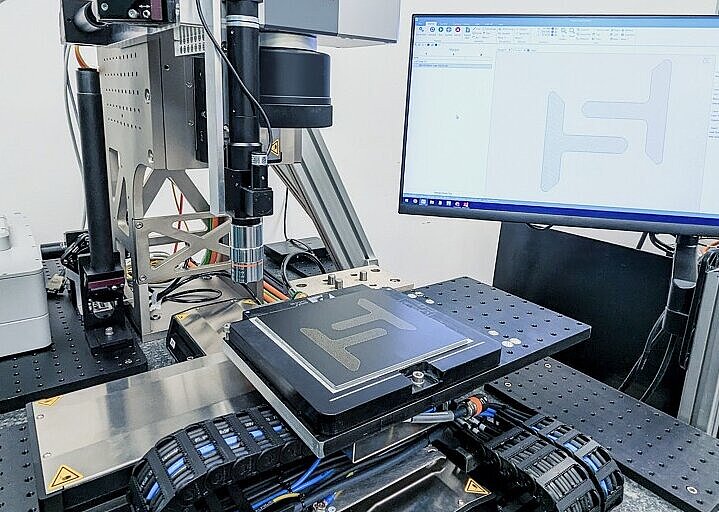

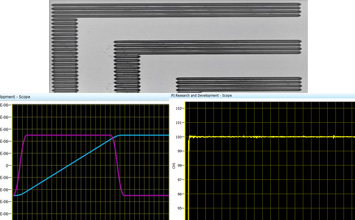

Example configuration for TLS Kanga Laser Micromachining Platform showing:

- SCANLAB excelliSCAN galvo scanner

- Physik Instrumente precision XYZ stages

- ACS Motion controls with XL SCAN package

- A precision vision system for sub-micron vision measurement

- A height sensor for 3D mapping of parts adjusting for part height and flatness variations

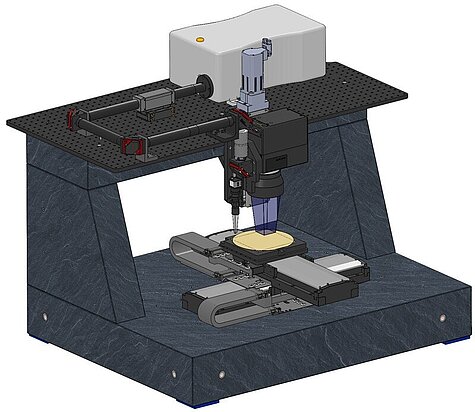

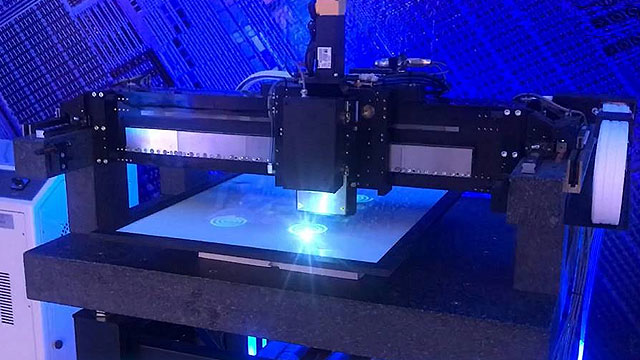

The Automated Laser Wafer Platform by Turner Laser Systems can be configured for your specific manufacturing needs to fit the right laser source, beam delivery, motion systems, wafer-handler, and integration of custom product fixtures, making this an extremely versatile machine for manufacturing your product.

To learn more about our partner, Turner Laser Systems:

visit www.turnerlasersystems.com

Or contact Mark@turnerlasersystems.com