Improving Laser Drilling Performance with a Novel Motion Control Method

Whitepaper: Piezo-Based Mechanisms in Micro-Hole Drilling Systems

Ultra-fast lasers have enabled laser drilling with unprecedented precision, especially when it comes to creating micro-holes in various materials. These breakthroughs enable the utilization of cold ablation to produce consistent holes, minimizing the need for extensive post-processing. This approach is gaining significant traction across a spectrum of applications, including aerospace component cooling, fuel injection nozzles, inkjet printer heads, and the formation of microvias in PCBs.

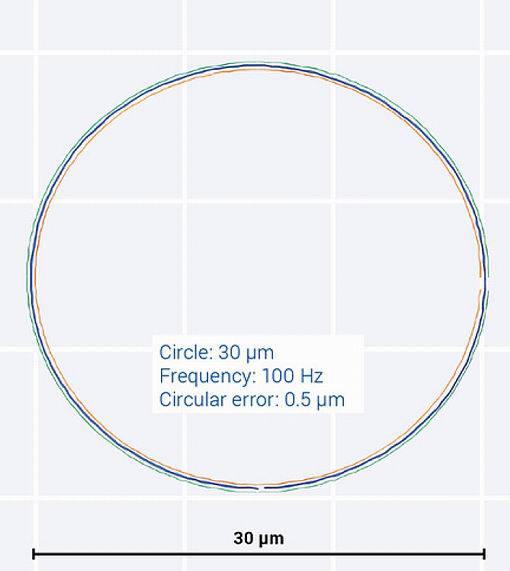

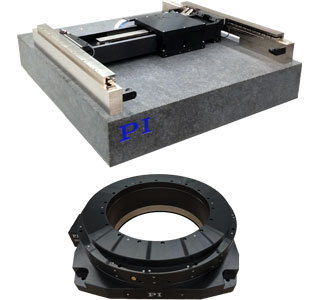

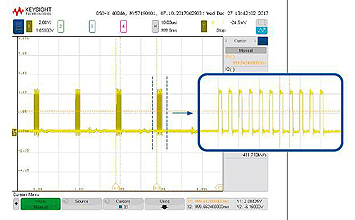

Motion control plays a key role in the drilling process. System designers have the flexibility to select from a multitude of motors, scanners, controllers, and make decisions regarding whether to mobilize the laser or the material being worked on during the drilling process. Additionally, the option to reposition both the laser and the sample concurrently exists, necessitating seamless communication between the various components within the positioning setup.

Our laser drilling white paper gives an overview of different control technologies and provides insights into a novel, piezo nanopositioning scanning stage-based solution to achieve unprecedented precision and throughput.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy