Motion Systems and Automation Controllers Help Improve PCB Manufacturing: LDI / Stencils

Advanced software modules integrate gantry control and laser control.

Synchronization of lasers and precision motion stages is crucial for advances in electronics manufacturing. Here, we explain how they relate to two techniques - PCB stencils manufacturing and Laser Direct Imaging (LDI).

How Motion Control and Laser Control enable Stencil Manufacturing

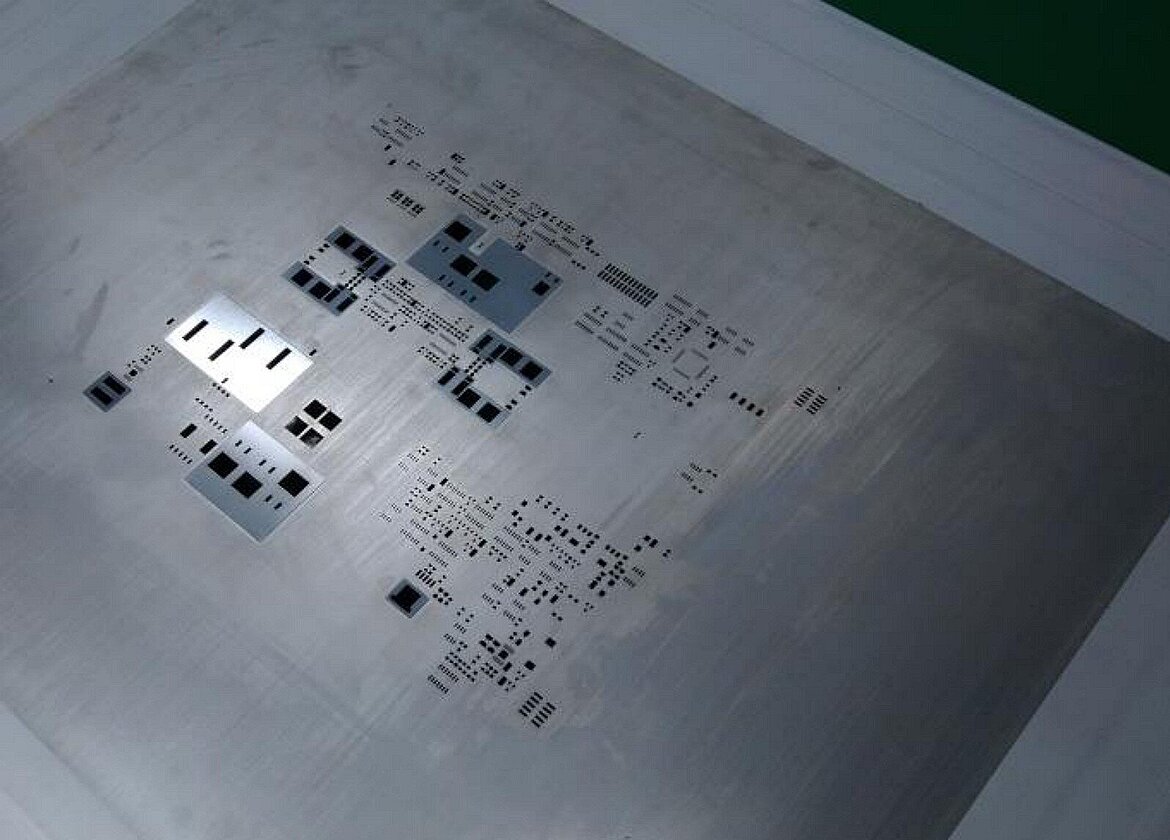

Stencils are used in PCB assembly automation with Surface Mount Technology electronics components. Stencils control the right amount of solder paste applied to the pads. The smaller the components, the higher the requirements on the tolerances.

To achieve the required precision, the stainless-steel stencils are laser machined. With every new electronics generation, feature sizes are getting smaller requiring faster, higher precision motion control and mechanics systems with tighter synchronization of motion and laser control.

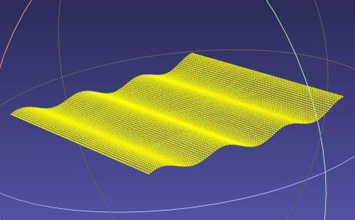

Controlling motion in the X-Y plane is not enough for the latest generation of “multi-level stencils”. These step stencils create voids to optimize solder paste control or to correct coplanarity problems. The production of these types of stencils requires the addition of a Z-positioning stage to the motion platform, to provide fine control in the vertical direction to process at different heights.

Motion Control and Platform Solutions Improving Throughput and Precision

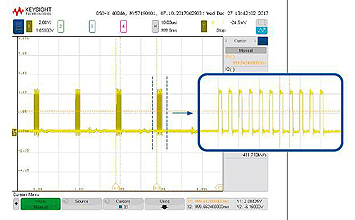

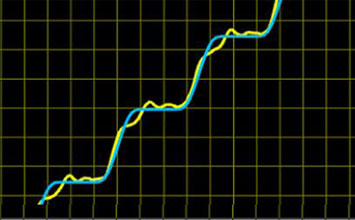

High precision corner and edge quality can require a motion controller that can intelligently and automatically control velocities so that mechanical acceleration limits are not exceeded. For maximum throughput, running the whole process with a low acceleration setting is not an option. Advanced, motion controllers, such as PI’s ACS-based A-824 and G-900 high performance series with EtherCat connectivity, provide “look-ahead” intelligence in their motion profile planning. This allows the controller to take the appropriate action to automatically reduce speed in situations where errors may exceed specification. This generally happens in sharp cornering. “Sky writing” is another option for optimizing the quality of corners. It eliminates the need for a sudden stop or an abrupt change in velocity that would increase cutting time and cause cutting errors.

The ServoBoost and PILOT algorithms are two more tools allowing the controller to manage higher speeds and accelerations of the linear stages or rotary stages than would be normally possible. They also automatically reject disturbances created by motion which can reduce cut quality due to machine instability.

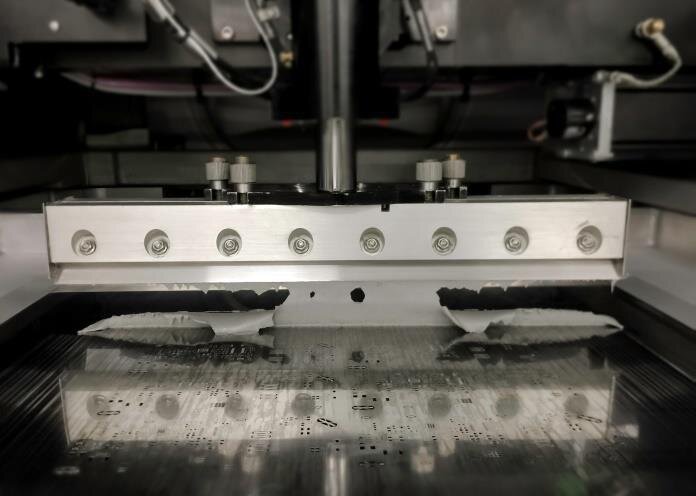

High speed laser machining needs advanced methods to control laser power and laser pulse placement to produce high quality cuts. The ability to dynamically adjust laser power and the on/off position placement that is directly linked to the motion profiles for both position and velocity can be achieved using our LCM (Laser Control Module). The LCM provides a direct link between motion and the laser. This provides the highest level of cut accuracy even when the feature size is small, and the cut speed is continuously changing.

Platform Solutions

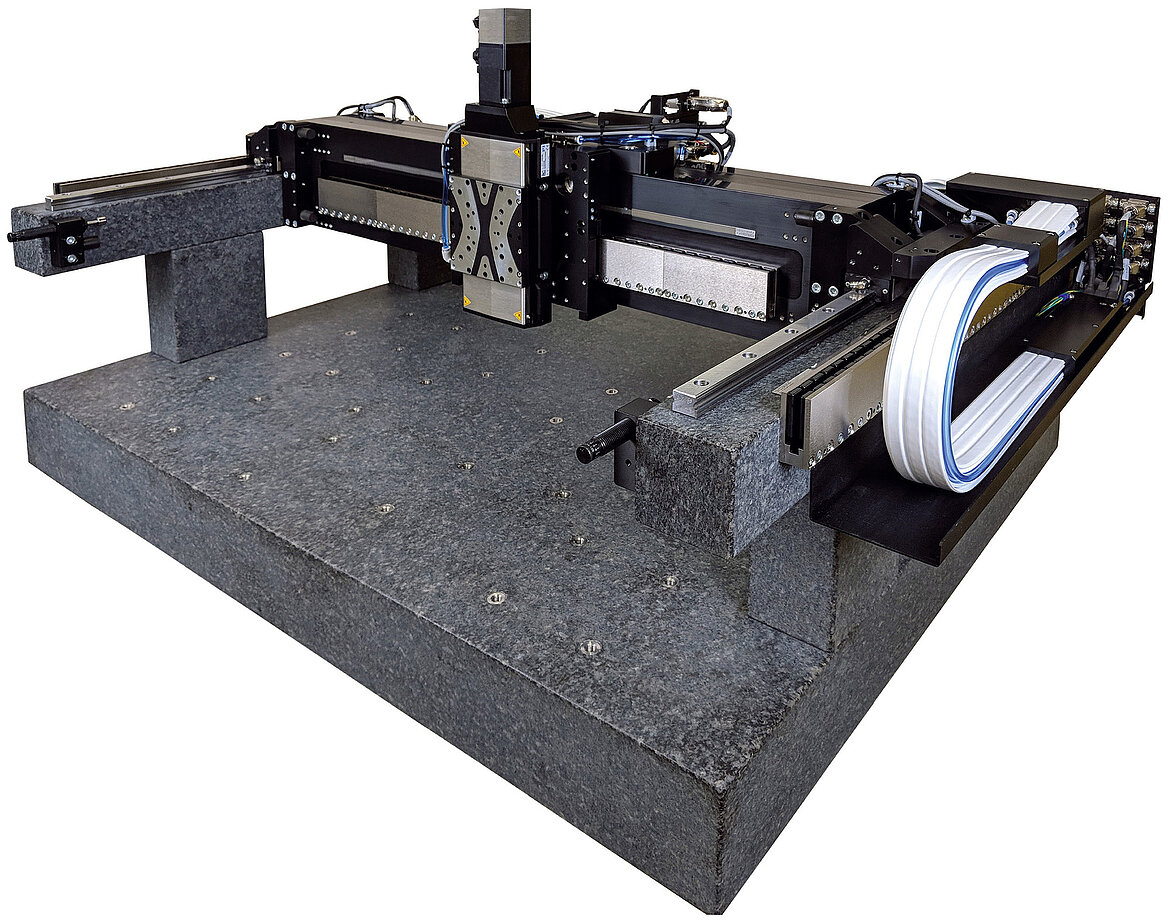

Gantry motion systems are the typical approach to provide the long travels and high speeds required to transport the stencil cutting laser. The stencil plate is stationary under a movable portal (or bridge) which positions the laser head above the stencil to perform the cutting operation. PI’s scalable gantry solutions offer numerous mechanical, electrical, and control elements that differentiate us from other offerings.

PI gantry systems use dual driven motors with independent encoders on the base axis. These provide higher power and the ability to compensate for each side’s variations in motion. Using a flexible joint rather than a rigid design and taking advantage of “Active Yaw Control” allows light weight machine design and class leading orthogonality of cuts during high speeds. The incorporation of absolute measuring encoders negates the risk of startup binding and removes long referencing routines which are common on many machines based on incremental encoders. Dedicated gantry control algorithms ensure that performance is consistent across the whole XY area. The controller can trigger the laser off a virtual axis.

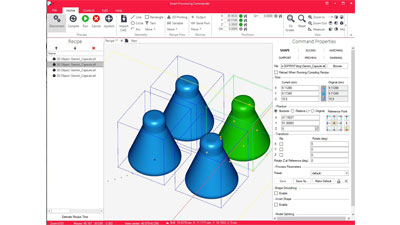

Our Advanced CAD/CAM drawing package called SPC can import various drawing files including Gerber. Multiple tools for laser synchronization are available. The software provides comprehensive “live” motion visualization.

Laser Direct Imaging (LDI)

Another method to create PCBs is based on a laser-processing technique called Laser Direct Imaging. This method, known from the semiconductor industry (laser direct patterning), can provide much higher precision and smaller feature sizes compared to the traditional ways of producing PCBs by photo-tool based lithography.

Laser Direct Imaging eliminates the need for creating a mask and thus also the downside of photo-tools, such as distortion or degradation caused temperature and humidity changes, or by dust and scratches. Because of the high flexibility of the direct write technique, LDI is also ideal for small production runs or prototyping. LDI can also provide a better fit, especially important in modern multi-layer PCBs and flexible PCBs.

Precision Motion Control - Straightness and Yaw Control Matter

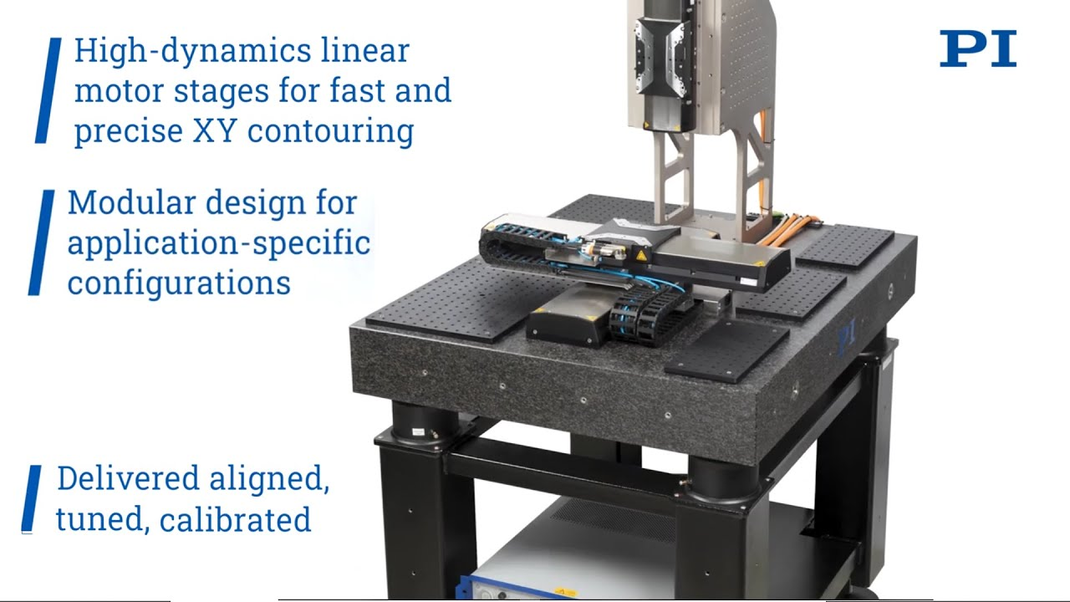

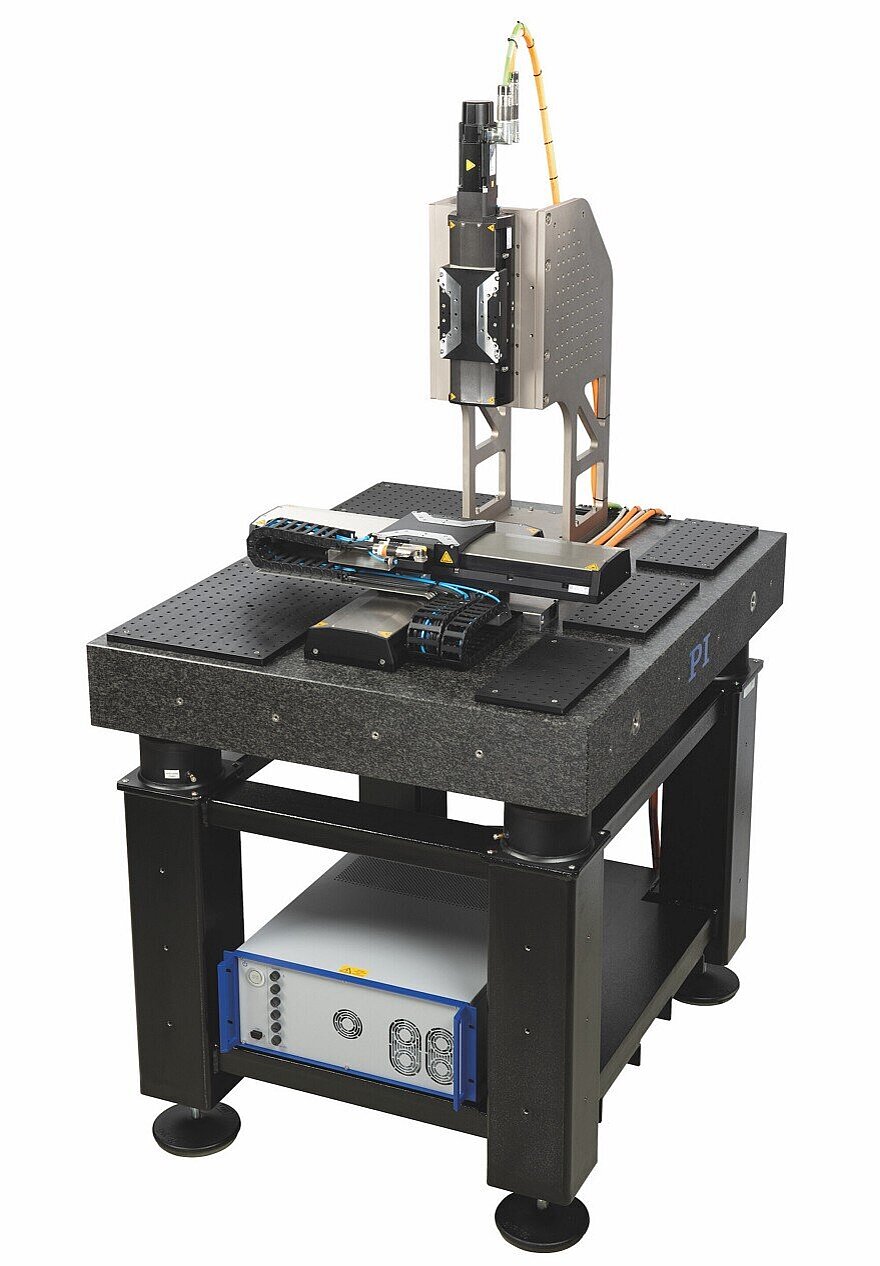

Using a direct laser write technique requires (in addition to the laser) a high precision XY motion stage, and a steering device to control the laser beam (such as a galvo scanner, voice-coil scanner, polygon scanner, Digital Micromirror Device).

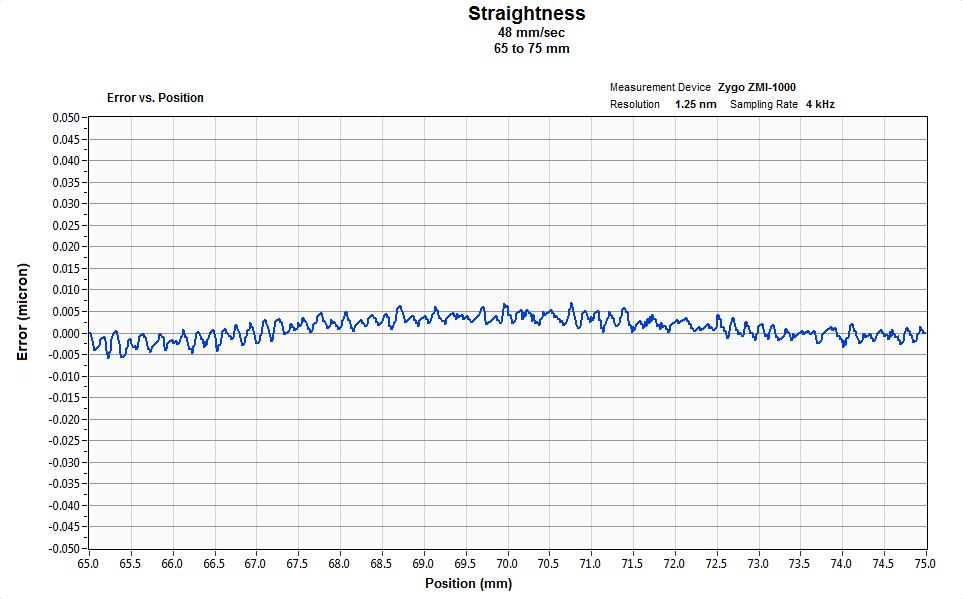

For good results, linear stages with excellent straightness and minimal yaw errors are critical.

Products with extremely good yaw control are often based on air bearings, such as the A-123 PIglide Air Bearing Slide family. When tip/tilt motion errors need to corrected, low profile Z-Tip-Tilt stages can be added. Low profile air bearing rotary tables are also available if high resolution rotation needs to be added.

The high-performance ACS motion controllers also provide excellent capabilities for extremely tight synchronization between with laser and the positioning stages. PI’s Advanced PILOT Motion Algorithm helps reduce vibration while speeding up the settling process. Other related applications are solder mask patterning, laser direct patterning, and flat panel display manufacturing.

If you need suggestions on what system will provide the best performance and ROI in your motion / laser application, please contact a PI engineer.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy