3D Printing - Direct from Digitized Data - Based on STL and other File Formats

Using Gantries and ACS-Based Motion Controllers

Background on the STL File Format

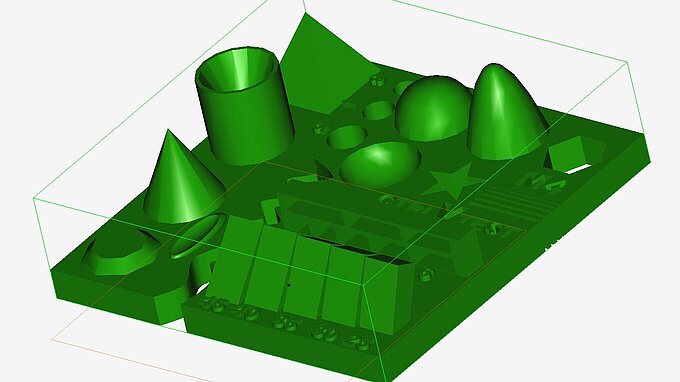

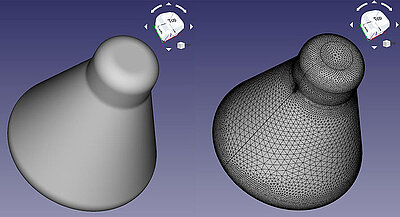

The StereoLithography (STL) file format was developed first in the late 1980s for 3D Systems, when additive manufacturing was in its infancy, following the invention of the first Stereolithographic 3D Printer. The challenge was to encode and transfer 3D model information in a format that could be used by the printer in a layer-by-layer fabrication process. The solution was a 3D surface approximation using a closed polygon tessellated surface mesh formed by triangular facets (see below). Since that time, STL has come to be the de facto standard for 3D printing across numerous techniques, including both laser and/or direct material dispense at both leading commercial and research institutions.

State-of-the-Art Systems for Next-Gen Processes direct from STL

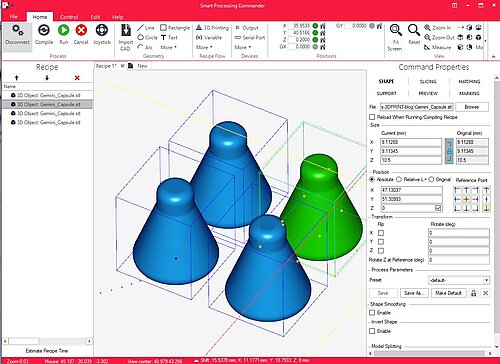

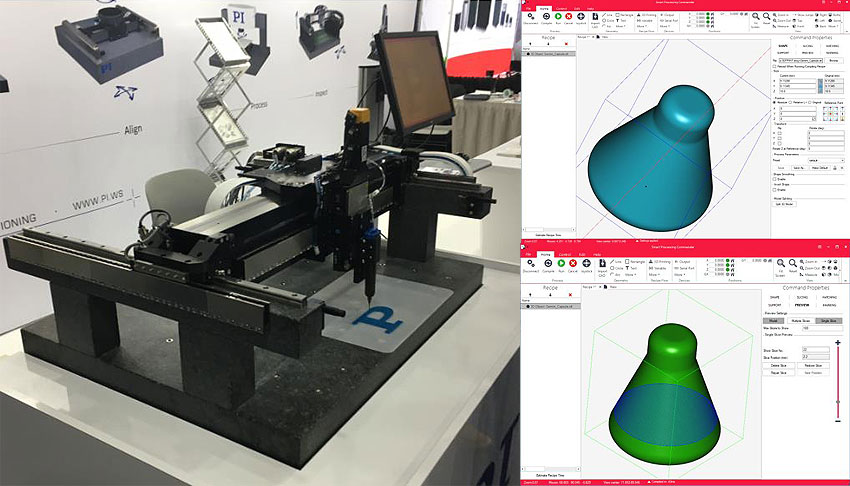

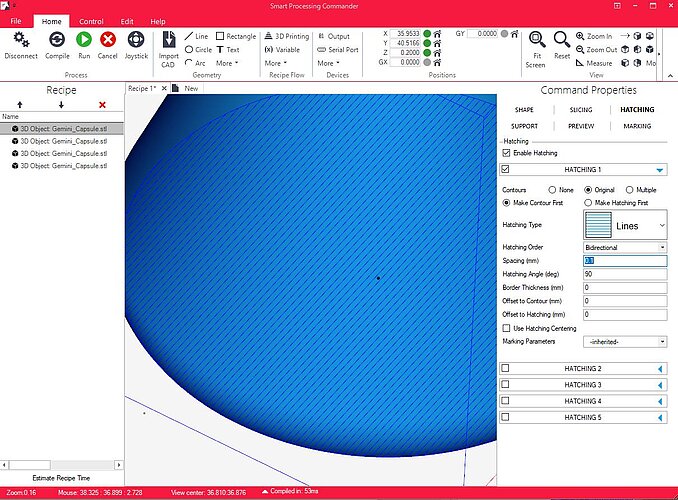

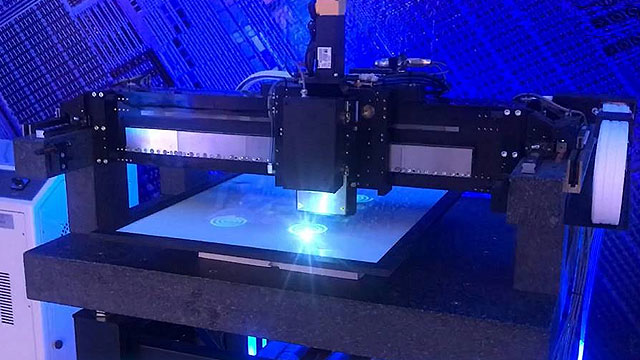

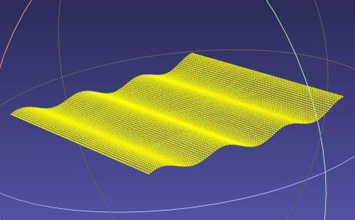

PI has developed a powerful 3D Print System Interface software working direct from STL files. It uses the ACS motion controller’s Smart Processing Commander (SPC) software that offers complete system control in an intuitive interface that draws on all the capabilities of the ACS controller, including XSEG, Advanced Gantry Control, LCM (EtherCAT® Laser Control Module) and ServoBoost.

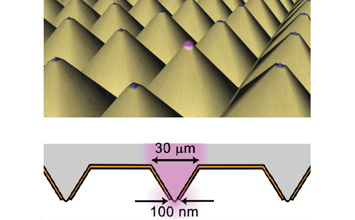

Intended to support next-gen laser and direct material dispense 3D Printing processes in a single interface, ACS SPC can be used for multi-purpose next gen additive manufacturing R&D platforms, or it can be customized to pass through on commercial OEM 3D Print systems. When working with STL files, the conversion, slicing options, process parameters, and job execution are in a single user-interface with flexible process control, capable of direct integration of multiple dispense devices as well as lasers and/or galvos along with machine vision, autofocus and/or surface height sensors.

G-Code in Support of STL Files

ACS motion controllers are also G-Code compatible and systems can be integrated on third party CAD/CAM packages with G-code direct from STL files converted on third party packages like Slic3r. In some cases, post-processors can be developed to support very specific functions not otherwise in a generic g-code implementation.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

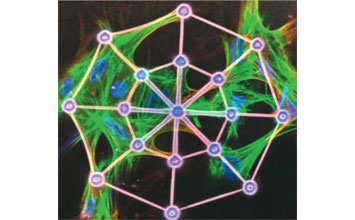

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy