In photonics and precision optics, alignment is crucial. Whether coupling a fiber array to a silicon photonics chip, steering a laser beam onto a mirror array, or positioning lenses inside a microscope objective, every micron — often every nanometer — counts. One often-overlooked but decisive capability in high-precision motion systems is the user-programmable pivot point, sometimes referred to as a virtual center of rotation.

What Is a Pivot Point?

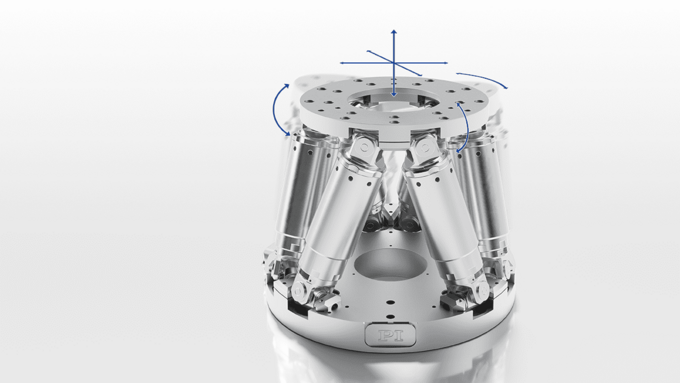

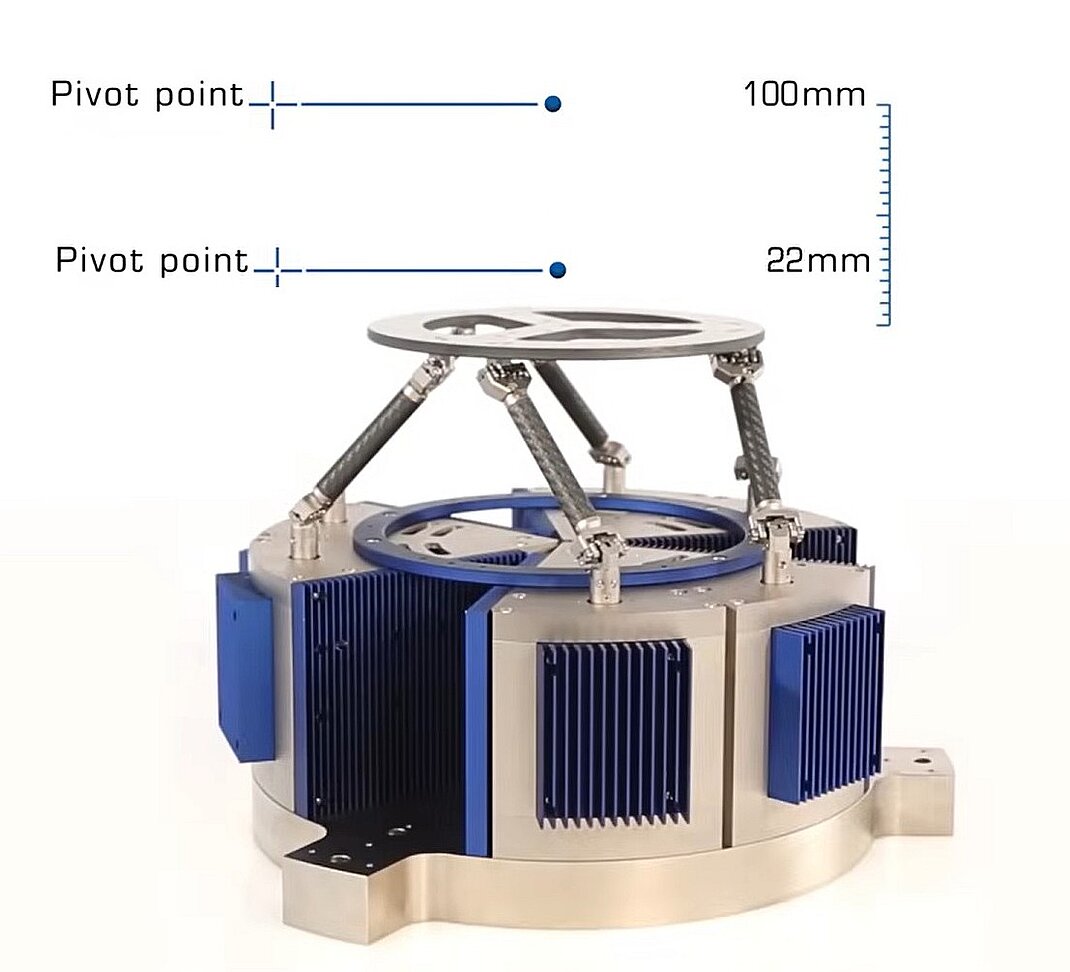

In multi-axis positioning systems, motion can include both translation (X, Y, Z) and rotation (pitch, yaw, roll). Every rotation occurs around a point in space: the pivot point.

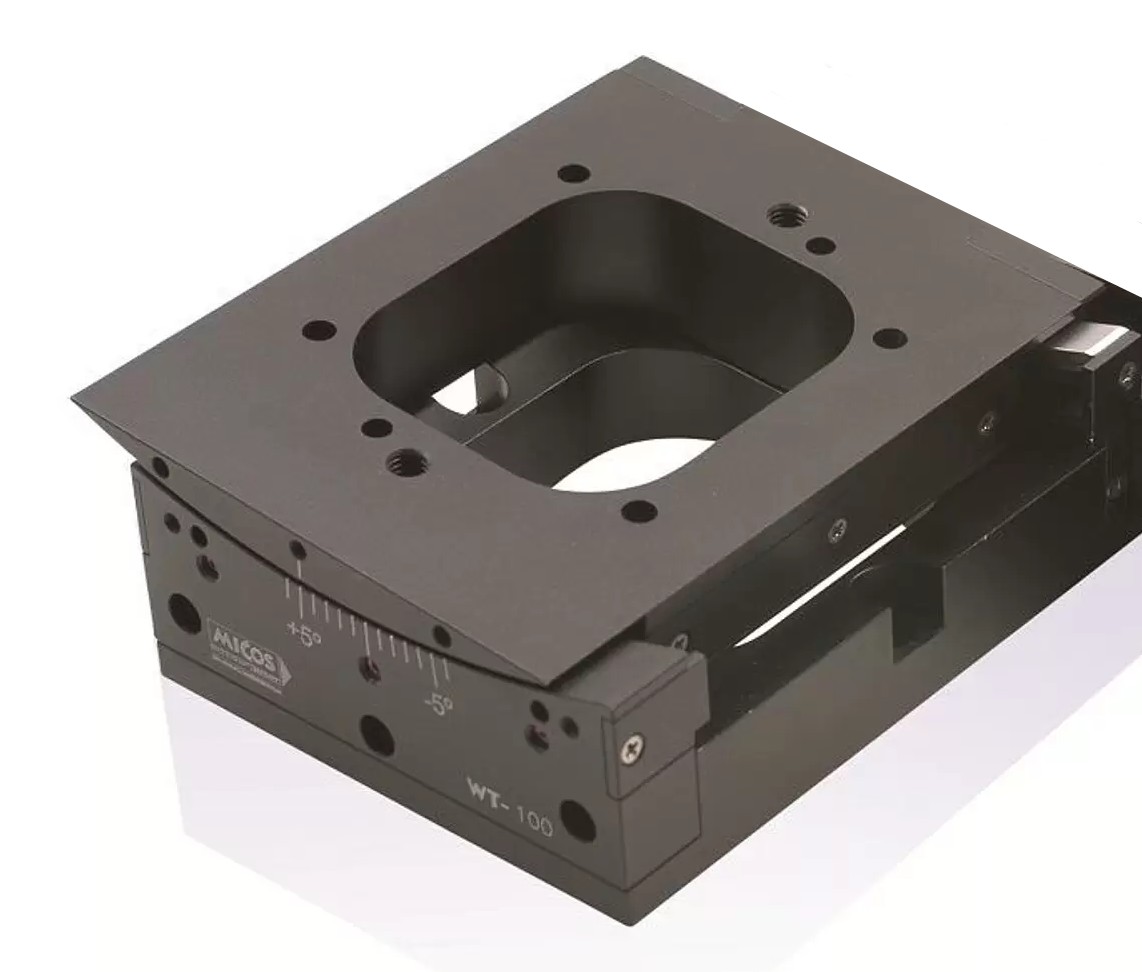

In a conventional mechanical setup, this pivot point is fixed by the geometry of the axes. When a user commands a rotation, the motion system physically arcs around that location — often far away from the optical interaction point. That can make alignment cumbersome, especially when rotations inadvertently introduce lateral motion at the point of interest.

Why Pivot Point Control Changes Everything

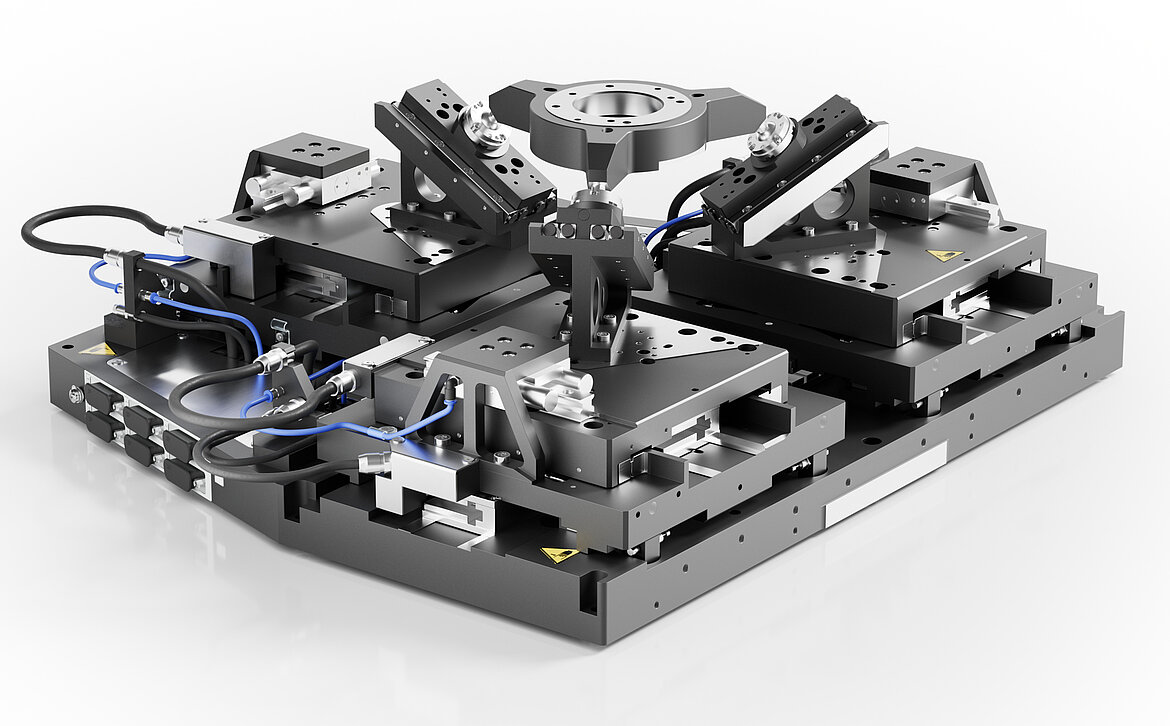

A user-programmable virtual pivot point allows the motion controller or kinematic model to redefine where the virtual center of rotation is located — in software. Instead of being locked to a mechanical reference, users can specify any point in 3D space (e.g., at the tip of a fiber, at the focal plane of a lens, or at the center of a photonic device).

When this virtual pivot is defined, rotational and translational motions are automatically recalculated so that all commanded rotations occur around that chosen point.

The result:

- Pure angular motion at the optical interaction point, without lateral drift.

- Faster, simpler alignments — no need to mechanically reposition multiple axes after each small rotation.

- Higher precision and repeatability, since alignment algorithms can work directly at the optical center.

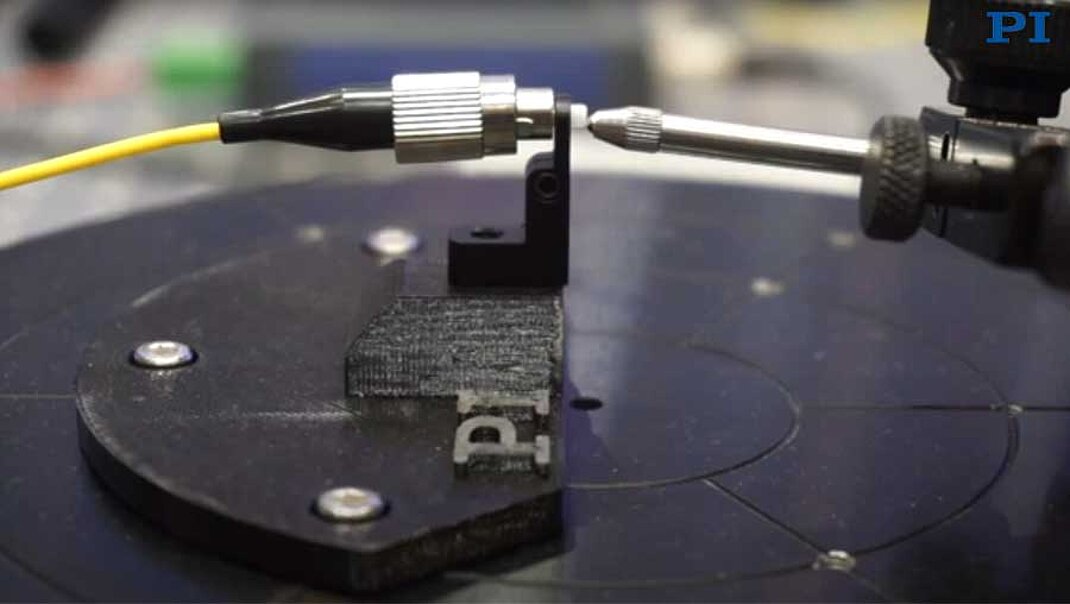

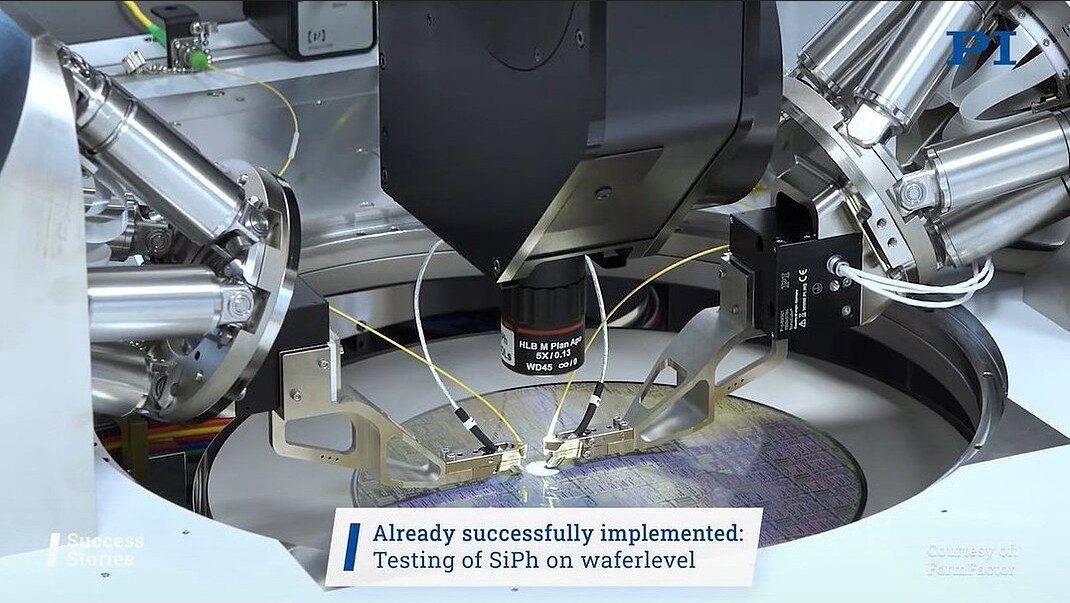

Example: Fiber-to-Chip Alignment

In active alignment of fiber arrays to photonic integrated circuits (PICs), even a sub-micron lateral shift can reduce coupling efficiency significantly.

Without a programmable pivot, a pitch or yaw adjustment to optimize coupling would also introduce lateral motion, requiring multiple iterative corrections.

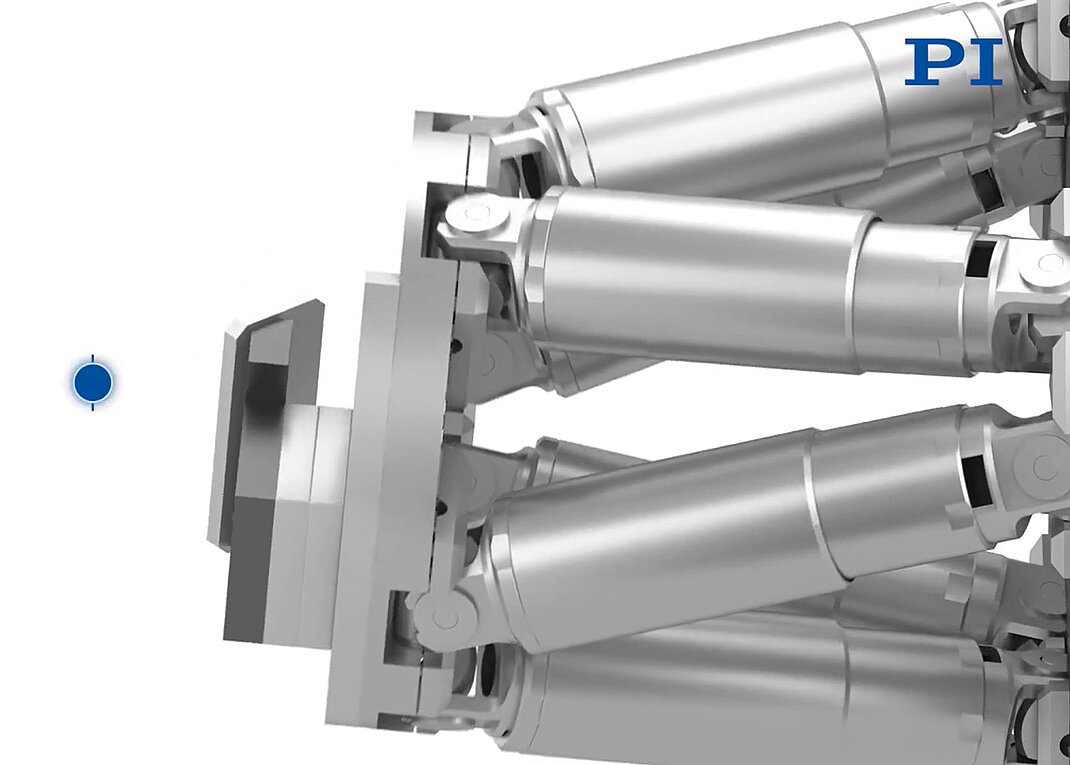

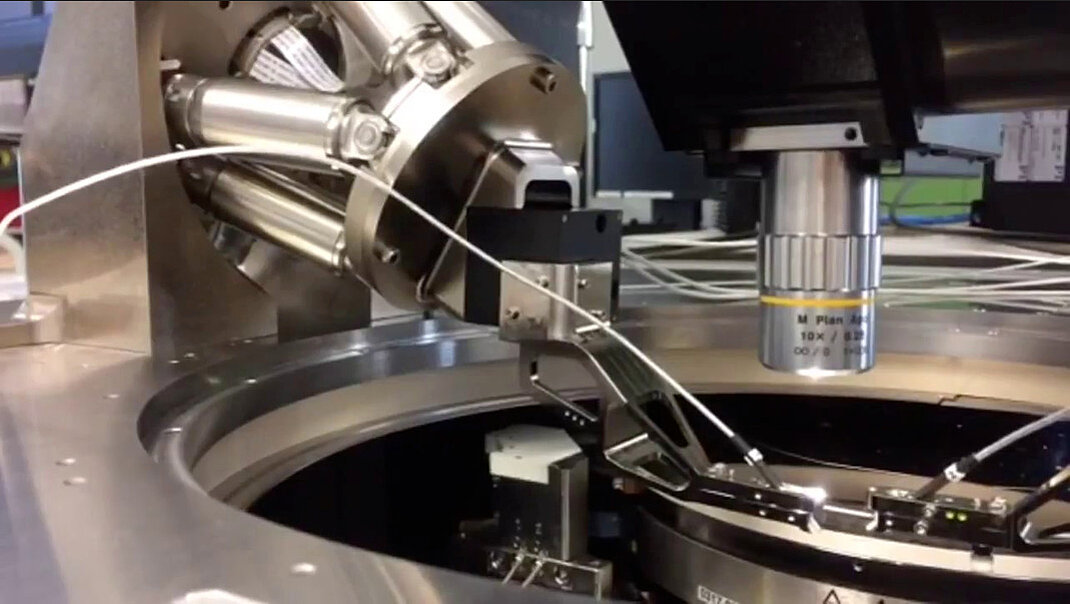

With a hexapod (parallel kinematics) or stacked multi-axis system (serial kinematics) that supports a programmable pivot, the virtual rotation center can be set directly at the fiber tip. Each angular adjustment then keeps the fiber tip stationary in space while changing only its pointing — drastically improving speed and yield in automated photonics alignment.

Optical System Design Advantages

- Beam Steering: Mirrors or lenses can be rotated about the beam waist or focal point, preserving beam alignment through the optical path.

- Microscopy and Imaging: Objectives can be tilted or focused without displacing the optical axis relative to the specimen.

- Metrology: Interferometers or detectors can be rotated about a reference point in the optical path, simplifying calibration.

How It’s Implemented

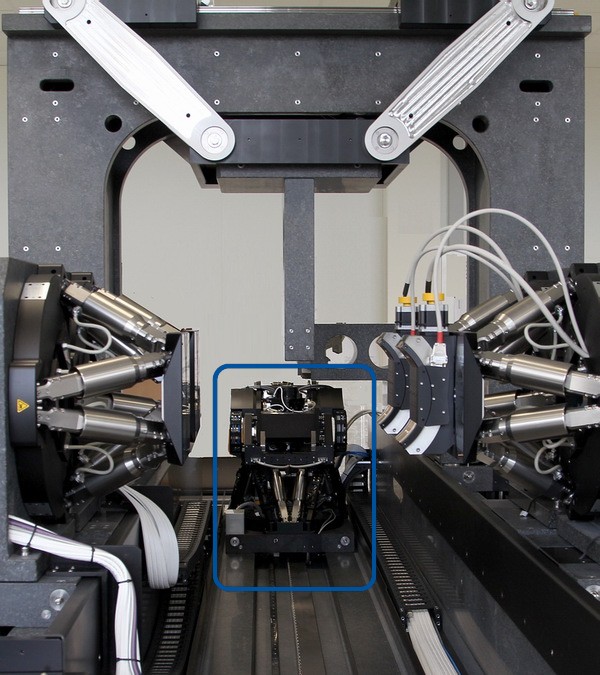

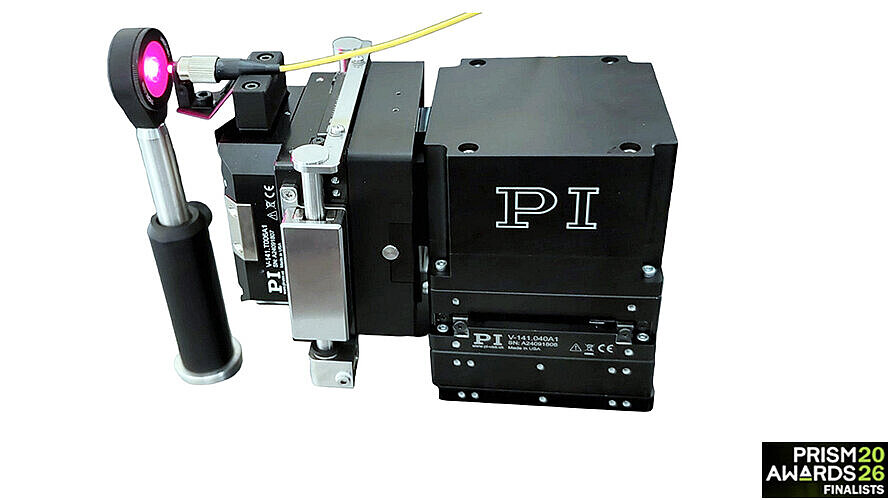

Systems such as PI’s hexapods, parallel-kinematic nanopositioners, and the PINovAlign modular alignment system utilize controller platforms with built-in kinematic models that automatically perform the required coordinate transformations, making the process transparent to the user.

When a user defines a pivot point position, motion commands are transformed in real time to maintain that virtual rotation center.

This capability also integrates seamlessly with automated alignment algorithms — such as FMPA (Fast Multi-Channel Photonics Alignment) — ensuring precise multi-DOF optimization without introducing parasitic motion.

In Summary

The user-programmable pivot point is far more than a convenience — it’s a critical enabler of precision and speed in modern photonics and optical alignment. By decoupling rotation from translation, it allows engineers and researchers to manipulate components around any desired optical reference point, streamlining alignment, minimizing error, and enabling faster automation.

Learn more on hexapod applications.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy