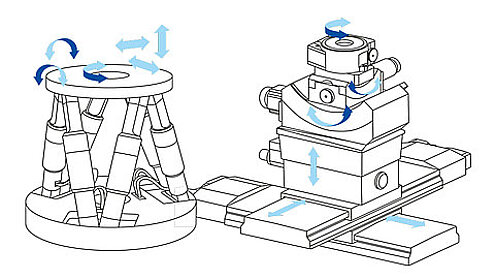

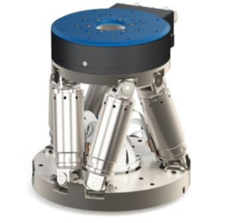

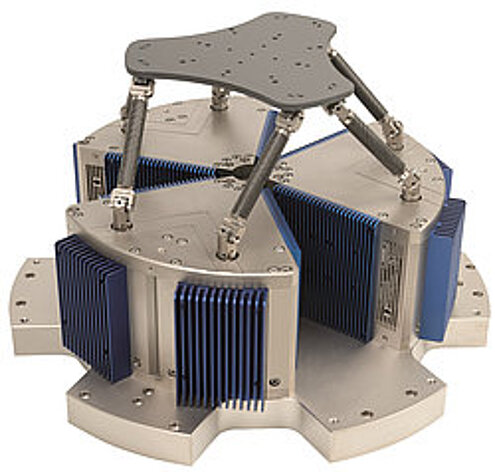

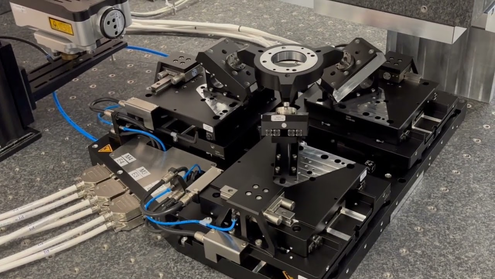

Hexapod 6-axis stages provide motion in all six degrees of freedom: X, Y, Z, pitch, roll, and yaw. These 6-DoF motion platforms, often referred to as Stewart Platforms, use six actuators arranged in parallel between a top and bottom platform. PI’s parallel-kinematics (PKM) precision positioning systems offer significant advantages over conventional 6-axis positioners with serial kinematics, including lower mass and inertia, improved dynamics, smaller footprint, and higher stiffness.

- Why should I use a Hexapod 6-Axis stage positioning system?

- Can it operate in any orientation?

- How do I control it?

- Is the motion smooth?

- How fast can the platform move?

- What are some common applications?

- Is it affordable?

- What software support is available?

- What environments can a PI Hexapod operate within?

- I only need 4 or 5 degrees of freedom!

- What if I need additional travel in one or more axes?

- What about servo tuning?

- Are parallel kinematics stiffer than conventional 6-axis stages?

- Can I program it in LabView?

- How reliable are they?

- How do I synchronize all axes?

- Can the Hexapod bind up?

- Can it be controlled manually?

- Are all Hexapods created equal?

- What are the advantages of working with PI?

- What is the smallest PI Hexapod?

Why Should I Use A Hexapod 6-Axis Stage Positioning System?

There are two approaches to achieving multi-axis motion: stacking individual stages or using a hexapod (Stewart Platform). Customers typically prefer the hexapod for its higher stiffness and the ability to define a virtual pivot point.

Hexapods achieve higher stiffness because six actuators move a single platform directly. This results in greater stability due to higher resonant frequencies and enables faster nanopositioning moves thanks to lower moving mass.

With a Stewart Platform, the center of rotation is defined in software through algorithms that coordinate the leg motions. By contrast, in a stacked multi-axis configuration, the center of rotation is determined by the bearings and mechanical alignment of the stage axes. The hexapod’s Virtual Pivot Point allows users to define the center of rotation to match their application needs—often aligning it with an optically significant point.

Can It Operate In Any Orientation?

Most PI hexapods are designed to operate in any orientation. Unlike systems that rely on external springs for preloading, which lose effectiveness when inverted, PI hexapods maintain performance regardless of mounting direction. Load capacity does vary with orientation, and PI provides simulation software to precisely calculate the forces on each actuator for any given setup.

Many of our hexapods are self-locking, even without power. Some, such as the H-815 compact industrial hexapod are also equipped with motor brakes.

How Do I Control It?

PI makes hexapod control easy. All PI Hexapods are controlled by dedicated controllers with built-in coordinate transformation for simple commands in cartesian coordinates. For most hexapods, only two cables are required to connect the controller to the mechanics—one for power and one for the motor and encoder signals. For increased versatility, they are available in user-selectable lengths from 2 to 20m. Controllers with Ethercat connectivity for easy integration into industrial processes are also available. PI hexapods come with a high-level command set. For example, the command to move to X=10mm position is MOV X10. The PI hexapod motion controller internally makes all path and position calculations for the individual legs. »More information on hexapod controllers

Is The Motion Smooth?

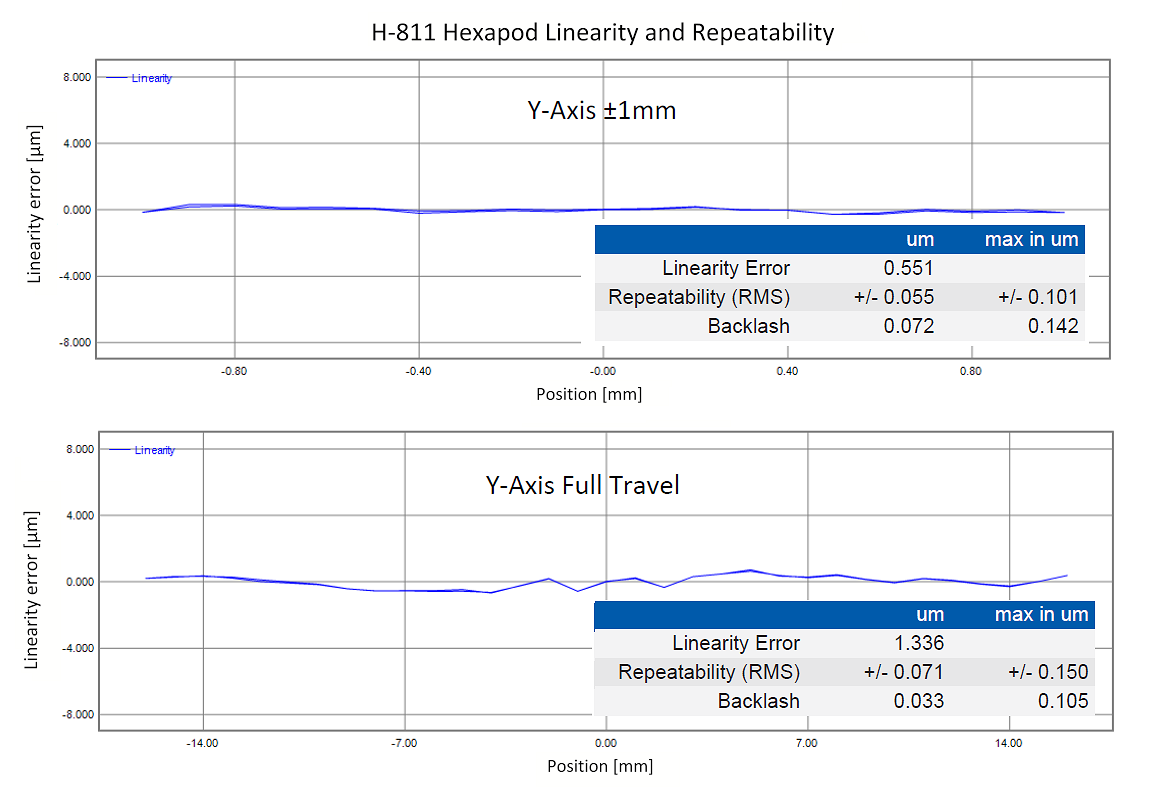

Yes. The PI controller coordinates the motion of each leg to generate smooth, precise movement at the platform. In addition, PI hexapods feature vector path planning, allowing the mechanics to follow customer-defined trajectories. PI Stewart Platforms achieve smooth motion, vector path execution, and defined trajectory following through the combination of advanced mechanical design and control technologies.

- PI Hexapod joints provide the full range of motion while maintaining the required precision. This is achieved through careful design and specification of joint geometry and bearing tolerances.

- PI Hexapod Controllers synchronize the individual leg motions in firmware, performing hundreds of thousands of calculations per second to ensure precise, smooth movement along the desired path.

How Fast Can the Platform Move?

The fastest hexapods from PI are driven by voice-coil linear motors. These 6-DOF motion platforms deliver dynamics up to 100 Hz and are commonly used to simulate motions such as hand tremor, vehicular vibrations, vessel movement, and drone dynamics.

For more information read »Hexapod in Camera Testing and »Hexapod 6DOF Motion Platform in Drone Testing.

A new lever-based hexapod concept also provides higher dynamics than conventional screw-driven designs.

What are some Common Applications?

Optics and Photonics

Active alignment of photonics components, precision assembly of optics, camera lens elements, optical metrology, 6DOF motion simulation, 6DOF motion cancellation

Vehicle Dynamics, Vehicle Manufacturing

6DOF motion simulation, 6DOF motion cancellation , automotive assembly

Astronomy & Aerospace

Precision active alignment of reflectors, large panels, etc

Industrial Production

Precision Machining, Alignment of Panels, Parts

BioMedical

Dental research [work], robotics in surgery

Big Science

Beamline Instrumentation

Is it Affordable?

Our hexapods combine uncompromising precision with exceptional value. PI has been manufacturing hexapods for over over 30 years – we started with custom hexapods for astronomical telescopes. Today, PI builds hexapods for industrial and scientific applications. Customers prefer them over stacked systems because they are cost-effective, robust, and deliver a lower total cost of ownership when used in their intended applications. PI hexapods start at under $30,000, with most models in the $40,000 to $60,000 range. Very large, high-load, high-precision hexapods can be more expensive.

Hexapod 6-axis positioning stages are also more precise than multi-axis stacks of individual stages.

In a stage-based multi-axis system, precision is typically specified per axis. However, overall system precision is significantly reduced because runout, angular errors, and flex in the individual axes accumulate at the working point of motion. When comparing prices, keep in mind that PI hexapods are backed by a two-year warranty, come with extensive software support and the PIVirtualMove simulation and emulation program. Customers also benefit from PI’s extensive experience and expert global support, with thousands of installed units worldwide as the market leader.

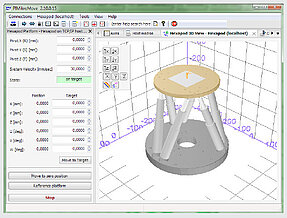

What Software Support Is Available?

The controller is purpose-built for 6-axis parallel kinematics, featuring internal coordinate transformation and path planning refined through more than threedecades of PI’s hexapod design and manufacturing expertise. Along with the PIMikroMove start-up software, the package includes LabVIEW drivers, Windows DLLs, and programming examples. Optional features include an EtherCAT interface, emergency stop functionality, and support for absolute position encoders. PI also provides workspace simulation tools, and with the Virtual Hexapod machine, customers can begin testing their programs before their hexapod is delivered.

PI hexapods use the PI General Command Set (GCS), a unified programming interface that offers numerous preprogrammed functions to accelerate orientation and application development. GCS is consistent across all PI motion controllers, simplifying integration and reducing development time.

Additional software:

PIMikroMove GUI

Is a very powerful graphical program ensuring rapid start-up right out of the box. It also integrates a Macro language, scan/align algorithms, and a data recorder for system analysis.

LabVIEW

PI provides complete open source LabVIEW drivers sets to facilitate programming.

Text-Based Programming Languages

All common programming languages under Windows & Linux with libraries and code examples.

Supported languages and software environments

C, C++, Python, Visual C++, Visual Basic, Delphi, LabVIEW, MATLAB, EPICS, TANGO, MetaMorph, µManager and all programming environments that support loading of DLLs

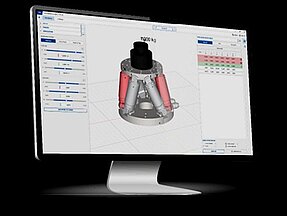

Simulation Programs

Determine work space and permissible load under different Hexapod orientations. A special software tool included with each PI Hexapod calculates and displays the limits graphically.

Emulation: Hexapod Virtual Machine (VM)

Saves cost and time because application programs can be developed and tested on the customer’s PC, before Hexapod delivery. VM emulates mechanics, controller and peripherals.

What Environments can a PI Hexapod Operate Within?

PI hexapods are available for a variety of environments. A vacuum option to 10⁻⁶ Torr is available for many models, and custom versions rated to 10⁻⁹ Torr can be provided on request.

Leveraging PI’s expertise in piezo ceramic motors, non-magnetic and EUV-compatible hexapods are also feasible, as well as systems designed for extended temperature ranges.

I Only Need 4 or 5 Degrees of Freedom!

A hexapod positioning system always provides six degrees of freedom. In many cases, the stiffness and virtual pivot point capability of a hexapod make it the better choice for 4- or 5-degree-of-freedom applications. In other cases, 4- and 5-axis applications may be better served by multi-axis stacks that combine 1- and 2-axis linear and rotary stages, for which PI offers a wide selection. In either scenario, PI works to understand the requirements of your application and guide you toward the best precision motion design path.

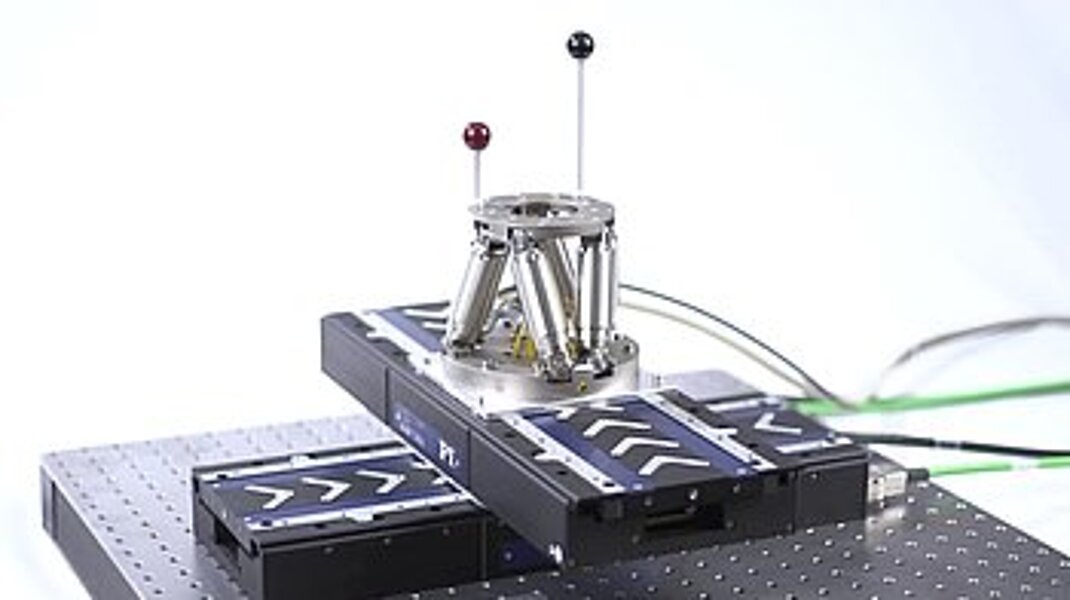

What If I Need Additional Travel In One or More Axes?

All PI hexapod controllers can handle 6+2 axes. In addition to the hexapod, two more linear or rotary stages can be controlled.

PI’s modular PlanarPod (SpaceFAB) design offers even greater flexibility, with the travel range in the X and Y axes limited only by the length of the linear stages.

What About Servo Tuning?

Unlike stacks of conventional positioning stages, PI hexapods typically require no adjustment of servo parameters. This is partly due to their parallel-kinematic design, which distributes the load symmetrically across all actuators. With a single common moving platform and very high system stiffness, the servo system is inherently more stable and forgiving. If tuning is required, the parameters are identical for all six axes—another advantage over serial kinematics.

Are Parallel Kinematics Stiffer than Conventional 6-Axis Stages?

PI hexapods are significantly stiffer than a stack of six individual stages. The moving platform is also much lighter than the combined mass of stacked stages. In a conventional 6-axis positioner, the bottom stage must carry the weight of five additional stages plus its own platform. By contrast, the hexapod’s high stiffness and low inertia result in a system that is exceptionally stable and highly responsive to motion input.

Can I Program it in LabView?

Yes, PI provides a complete software package with open-source LabVIEW drivers. We stay up-to-date with the latest LabVIEW versions, include the drivers free with the controller, and many of our customers use LabVIEW successfully with support from our teams in Shrewsbury, MA and Irvine, CA.

How Reliable are They?

PI hexapods are highly reliable. They use no exotic or overly sensitive components—only six identical actuators, precision high-load bearings, and robust cable management. The design and manufacturing have been continuously refined for more than 30 years. In addition, PI’s dedicated hexapod controller ensures independence from third-party firmware or hardware changes.

How Do I Synchronize All Axes?

You don’t need to—synchronization is handled entirely within the hexapod controller. The controller coordinates the motion of all six legs thousands of times per second. This process is completely transparent to the user, who simply enters the desired motion coordinates for the top platform.

Can The Hexapod Bind Up?

No. PI hexapods are designed without singularities and therefore will not bind.

Can It Be Controlled Manually?

Yes. Manual control is possible with the optional manual control unit.

Are All Hexapods Created Equal?

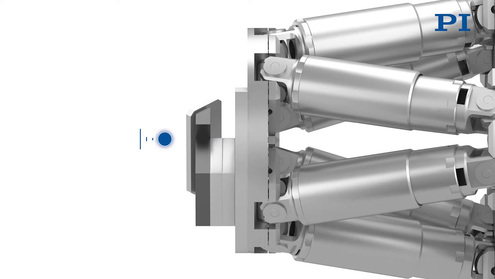

No. There are many ways to design a hexapod. PI offers several configurations, including systems with passive or active struts, motor brakes and self-locking mechanisms, servo-motor-driven designs, and piezo-motor-driven platforms. Most PI hexapods employ advanced, in-house–designed cardanic joints with Z-offset, providing superior stiffness compared to standard spherical joints. This design enables precise, backlash-free operation, even in arbitrary orientations.

What Are The Advantages of Working With PI?

- Experience: Since the early 1990s, PI has built more micropositioning and nanopositioning hexapods than any other company worldwide.

- Performance: Hexapod performance depends heavily on joint precision. PI designs and manufactures custom joints—such as offset cardanic joints for maximum stiffness and flexure joints for nanometer-level precision. Precision also relies on metrology, math, and control algorithms, where PI’s expertise and advanced test equipment provide a clear advantage.

- Complete Solution: Every PI hexapod and controller are designed specifically as an integrated solution and are supported by PI’s global network of experts.

What is the smallest PI hexapod?

PI’s most compact 6-axis piezo parallel manipulator delivers high-performance motion for fast photonics alignment applications. However, the smallest 6-axis positioning stage in PI’s portfolio is not a motorized hexapod, but a parallel-kinematics flexure stage designed for nanometer precision.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy