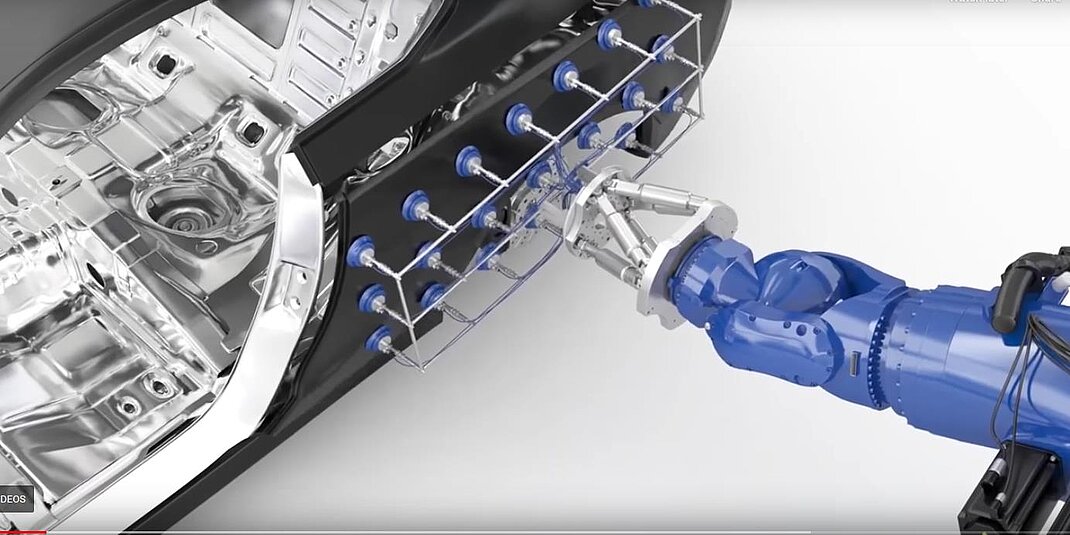

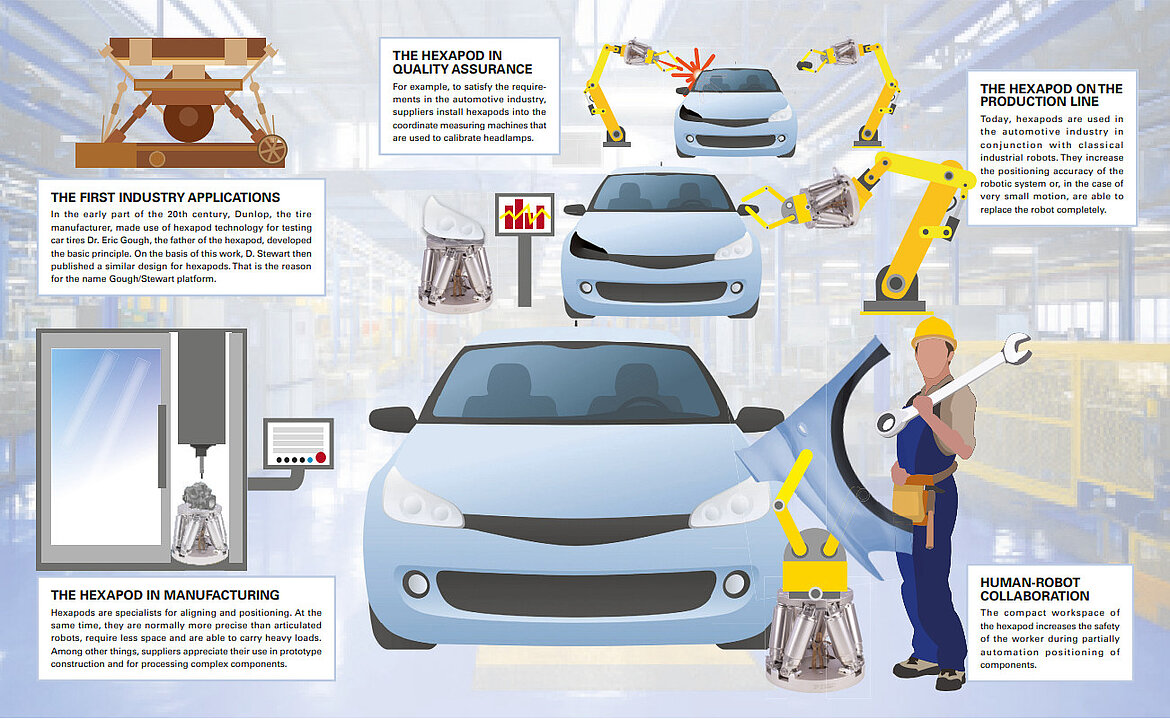

A Hexapod Robot is a 6-axis, parallel-kinematics machine often used for automated precision positioning and alignment of parts and components ranging from miniature optics to large panels. As the precision requirements in the automotive industry are increasing, the need for advanced robotics arises. Traditional robots are fast, can handle heavy loads, but lack positioning accuracy. Hexapod robots have a long history in precision alignment & micro-manufacturing automation, but were considered too precise for the automotive industry. The situation is rapidly changing.

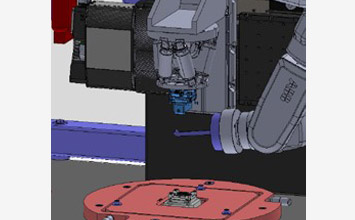

Modern hexapod controllers can communicate directly with a PLC or CNC controller via fieldbus interfaces, facilitating the integrating into the automation environment. Applications are found in quality assurance, test and metrology, prototype design and evaluation, and on the production line as a supplement to the traditional industrial robots or for the worker in partially automated processes.

Hexapods robots are not new to the automotive industry – on the contrary, one of the first industrial applications of parallel kinematic robots was tire testing under different angles, offsets, and loads. The first machine was designed by Dr. Eric Gough, who was working for a tire manufacturer in Birmingham, England.

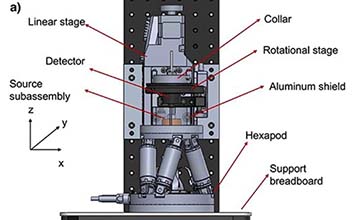

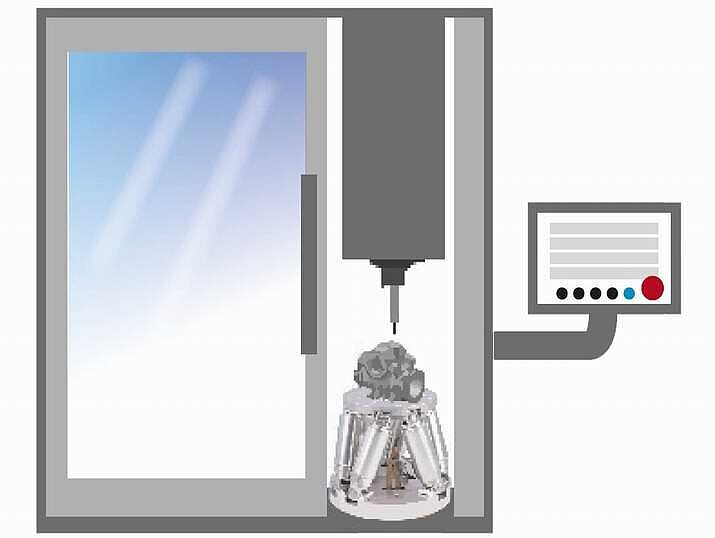

Today’s applications require much higher precision; first-tier automotive suppliers have discovered hexapods for coordinate measuring machines to calibrate headlamps and for the alignment of optical components that are becoming more and more mainstream for autonomous driving. Precision laser welding can also be improved with the help of hexapods.

Why Hexapod Robots?

Basically it comes down to smaller size, higher stiffness, dynamics, precision, and greater flexibility – the user programmable pivot point allows rotations around any center in space and multiple coordinate systems (work piece and tool can be set in software). Additional advantages are the lack of dragging cables as common with classical, serial multi-axis positioning systems.

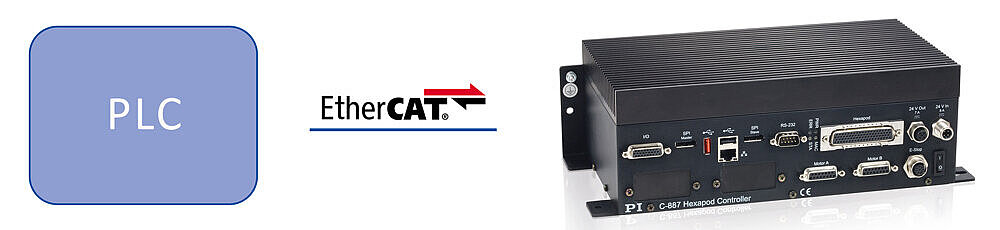

Hexapod Controller

The math behind the parallel coordinate transformation is handled inside the hexapod controller and completely transparent to the user, as all 6 degrees of freedom are commanded in Cartesian coordinates. PLC standard language can be used and the controller communicates with the hexapod via a standard protocol. In addition to TCP/IP and RS232, established fieldbus protocols, such as EtherCAT and PROFINET, are available. The hexapod system then behaves as an intelligent multi-axis drive on the bus.

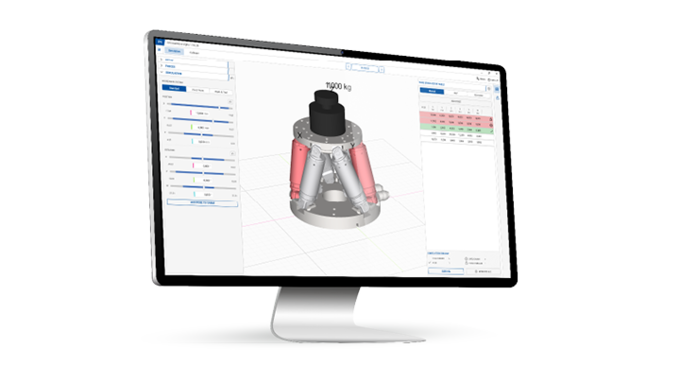

Simulation Software

Simulation software and a virtual controller allow application development before the hardware is installed. A plethora of programming tools, such as drivers, VI’s, collision avoidance software and a mobile app for wireless monitoring, are available to simplify implementation.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy