In this blog article, we are reporting on new applications of miniature six-axis hexapod positioning systems in the realm of structured microscopy, fabrication of optical elements, and radionuclide therapy. Hexapods are extremely versatile motion and positioning systems providing 6-degrees of freedom. PI hexapod positioners are backed by more than 3 decades of continuous development and improvements in mechanics, control electronics, alignment algorithms, and software.

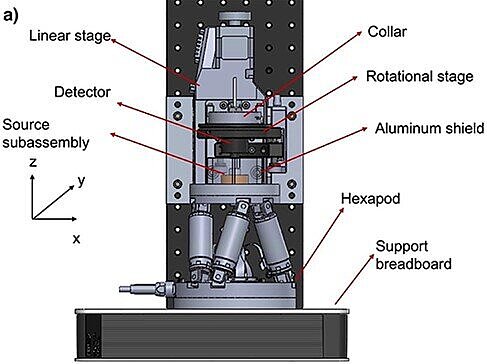

Miniature Hexapod Employed to Improve Radiation Therapy Standard

In their paper “Development and evaluation of a standard for absorbed dose to water from alpha-particle-emitting radionuclides” by Ahtesham Ullah Khan et al (2023 Metrologia 60 065003) present the design of measurement device for a new standard and the goal to improve radiation therapy.

The reason behind their work is the recent increase in clinically significant targeted radionuclide therapy and brachytherapy using alpha particles. Despite the increase, there is currently a lack of absorbed dose traceability to a standard within the dosimetry process.

The article discusses the development and evaluation of a standard for absorbed dose to water from alpha-particle-emitting radionuclides. Measurements of alpha-particle-emitting radionuclides are used for dosimetry in the field of medical physics and radiation therapy. They are important for determining the absorbed dose to water from these radionuclides, which is necessary for accurate treatment planning and delivery. The development of a standard for absorbed dose to water from alpha-particle-emitting radionuclides can improve the accuracy and reproducibility of these measurements, leading to better patient outcomes.

The hexapod is a device used in the measurement setup to allow for translational and rotational motion of the detector subassembly, as well as the establishment of parallelism between the detector and source planes. Its function is to manipulate the coordinate system based on rotational or translational shifts, allowing for precise measurements of absorbed dose to water. The source subassembly was affixed to a miniature hexapod stage (Physik Instrumente H-811.i2), providing translation and rotation in all three axes. Translation adjusted the air gap, while rotation ensured parallelism between the detector and source planes. The hexapod allowed rotation around any pivot point and dynamic shifts in the coordinate system. Due to the hexapod's limited 6.5 mm z-axis travel, a linear stage (Physik Instrumente L-509) with a 52 mm travel range was mounted on a breadboard.

The full article is available on IOP Science here: Development and evaluation of a standard for absorbed dose to water from alpha-particle-emitting radionuclides

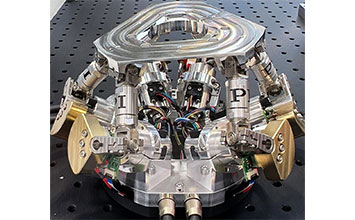

Miniature Hexapod in Hybrid Optical Elements Fabrication

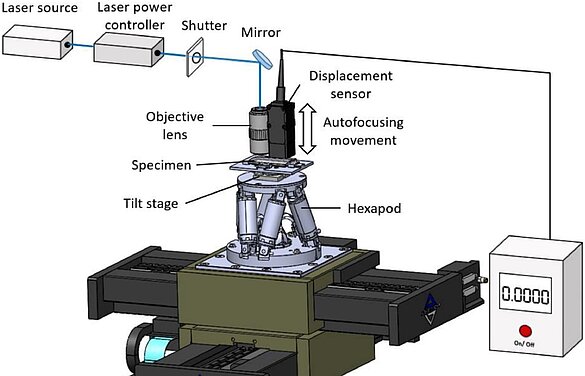

In the paper “Novel fabrication and designs for hybrid optical elements with wider angle field of view by using integrated direct laser lithographic system”, Nguyen Nu Hoang Anh et al report on a direct laser lithography system for the fabrication of wide field of view optical elements.

Hybrid optical elements combine refraction and diffraction to widen the field of view angle and enhance optical performance. However, manufacturing high-resolution diffraction pattern arrays covering curved surfaces with perpendicular normal vectors is challenging. This study presents a direct laser lithographic system with autofocus and high rotational accuracy for fabricating diffractive patterns on cylindrical lenses, enabling wider field of view hybrid optical elements. Novel designs like linear and elliptical zone plates focus light into lines and points, outperforming traditional diffractive optics by 25%. The authors propose a system that creates a 20° field of view, acting as a curved cylindrical lens array and 1D microlens array, with verified performance both optically and through simulation.

A 6-axis hexapod stage, specifically the H-811.i2 6 miniature hexapod, was used to rotate the chromium-coated glass specimen to various positions with high accuracy. The hexapod provides a rotational range in both θX and θY of 20°. It is placed on an XY linear stage, which allows movement in both X and Y axes over a distance of 200 mm. The hexapod stage is controlled by a computer program.

The purpose of using the hexapod stage, in combination with the linear stage system, is to achieve precise positioning and rotation of the specimen. This positioning is essential to ensure that the laser beam is illuminated perpendicular to the surface of the lens at the exposure point, facilitating the fabrication of hybrid optical elements with a wide field of view.

Read the full article Novel fabrication and designs for hybrid optical elements with wider angle field of view by using integrated direct laser lithographic system on Sciencedirect.com.

Miniature Hexapod Used in Production of Integrated Optical Device for Structured Illumination Microscopy

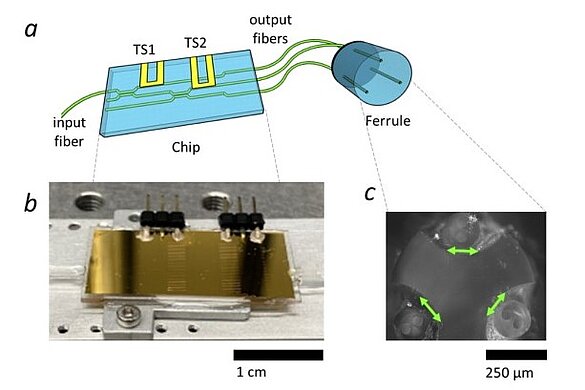

In the paper “Structured Illumination Microscopy is based on 2D structured illumination patterns” Matteo Calvarese at al describe the fabrication of an integrated optical device to advance structured illumination microscopy (SIM). The proliferation of portable and easily alignable SIM systems necessitates the innovation of methods for creating and shifting a light pattern across the microscope's field of view. In their study, the scientists introduce a miniaturized chip containing optical waveguides, splitters, and phase shifters, enabling the generation of a 2D structured illumination pattern suitable for SIM microscopy. The chip produces three coherent and precisely controlled point sources in phase, eliminating the need for additional alignment.

The device is installed on the illumination port of a widefield microscope and can be used as the light source for structured illumination, upgrading the system to a SIM microscope. Using three sources, a hex-SIM pattern can be efficiently formed and, by dynamically controlling the phase of the chip’s waveguides, the illumination pattern can be shifted over the field of view of a widefield microscope. The device was fabricated using a combination of 3D printing and microfabrication techniques. The precise positioning of three fibers in the ferrule was performed using a H-811 hexapod 6-axis stage and three cameras were used to monitor the process from three different viewpoints. The device was tested using fluorescent beads and biological samples, and the results showed that it can provide high-resolution images with improved contrast and resolution compared to conventional widefield microscopy.

The full article is published on Optica.org here: Integrated optical device for Structured Illumination Microscopy

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy