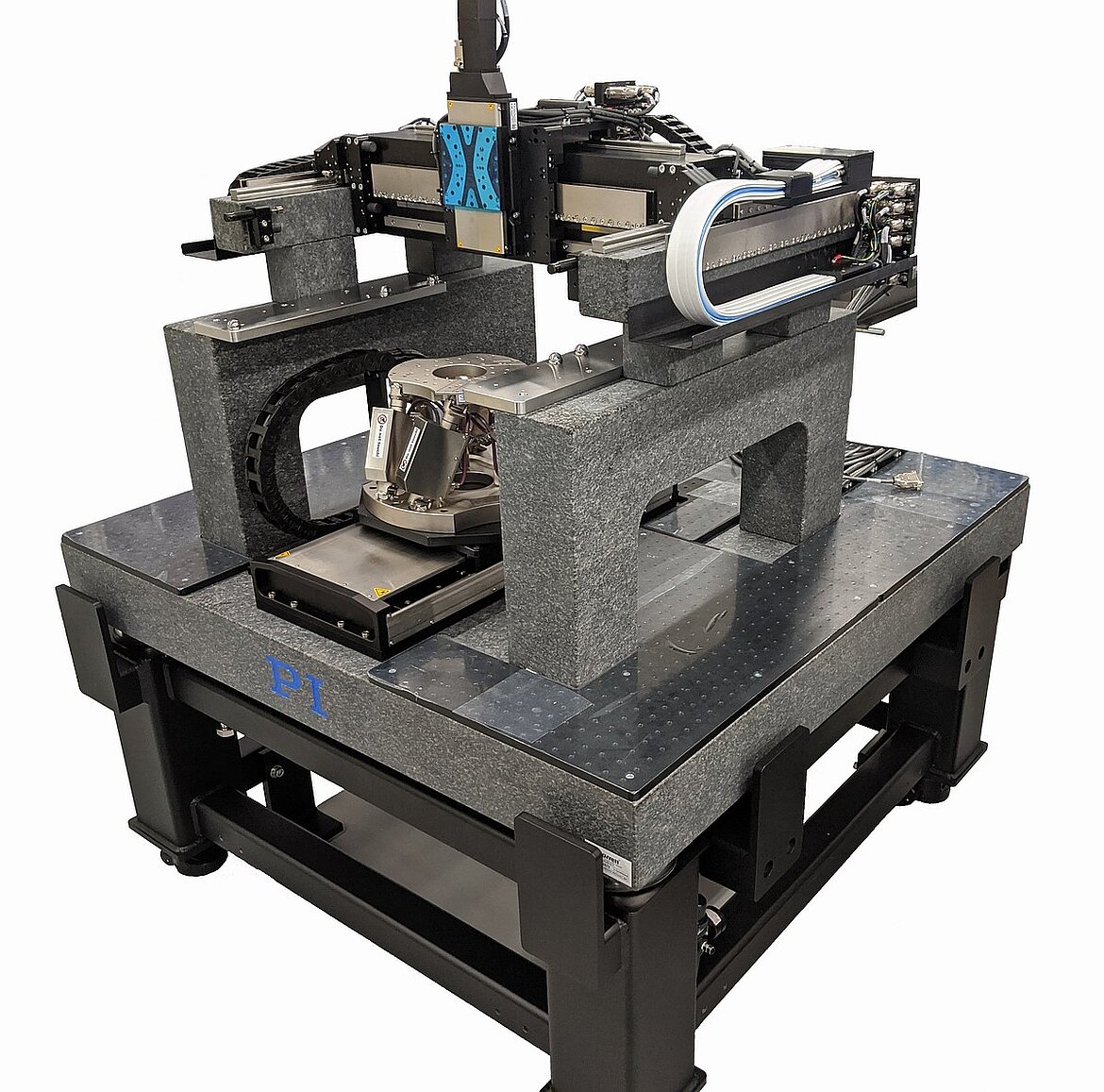

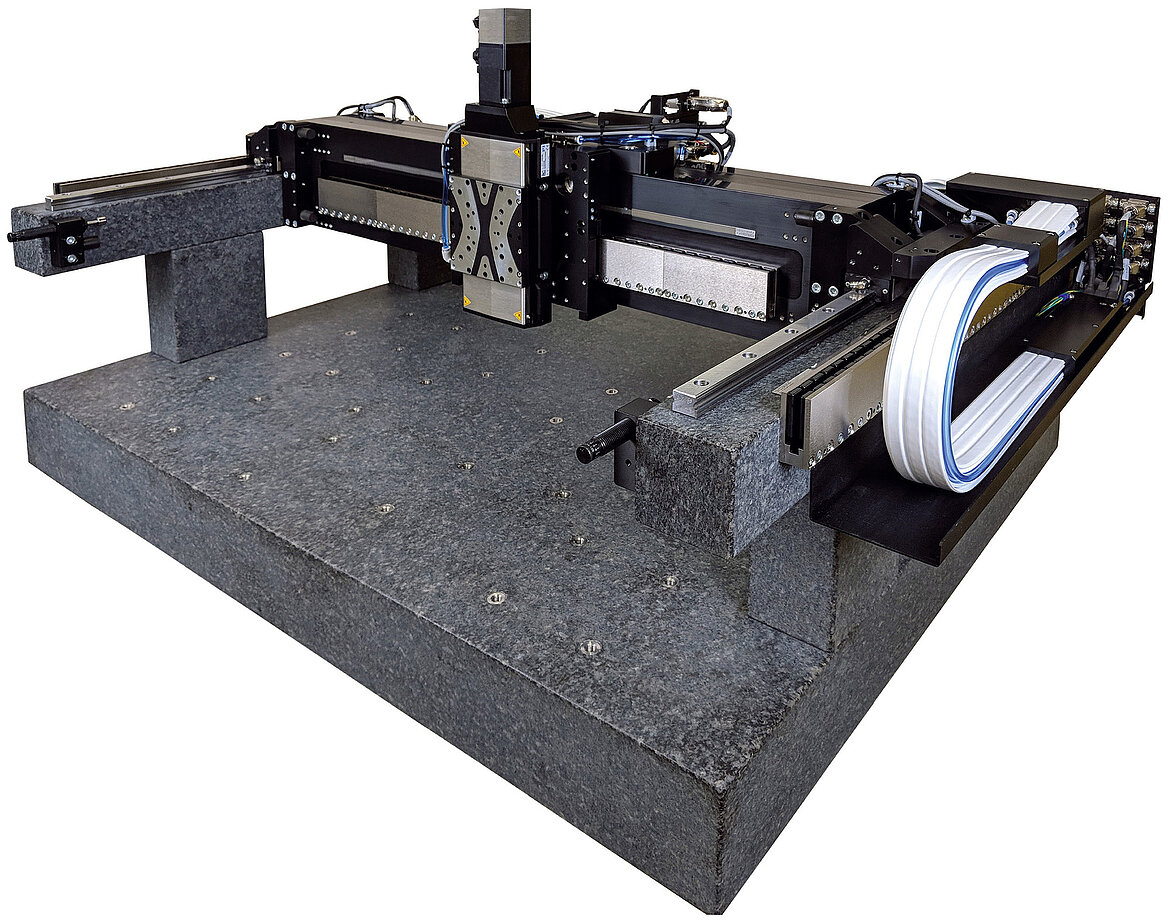

Designing, constructing, and controlling precision gantry motion systems is a multidisciplinary engineering challenge requiring deep expertise in structural mechanics, thermal modeling, mechatronics, and advanced motion control.

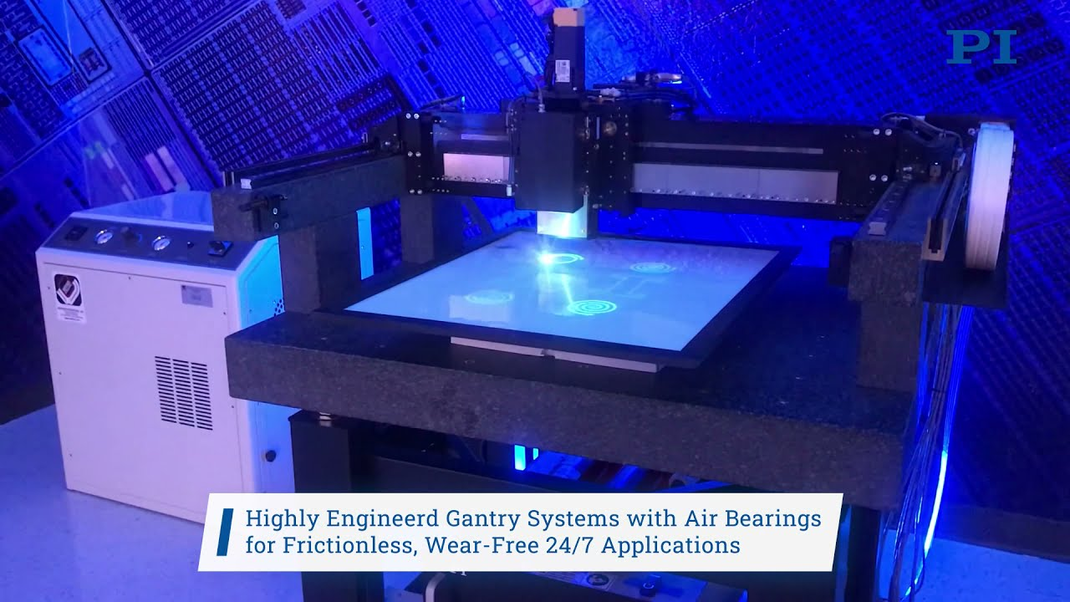

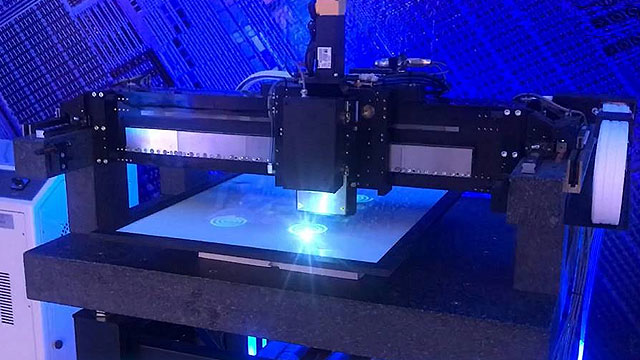

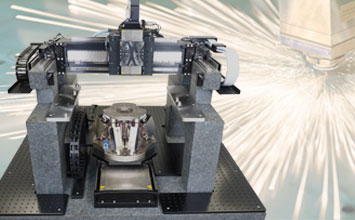

While multi-axis gantry systems are foundational to high-throughput automation — think semiconductor inspection, laser processing, and advanced metrology — the challenges behind making them precise, reliable, and production-ready are often underestimated.

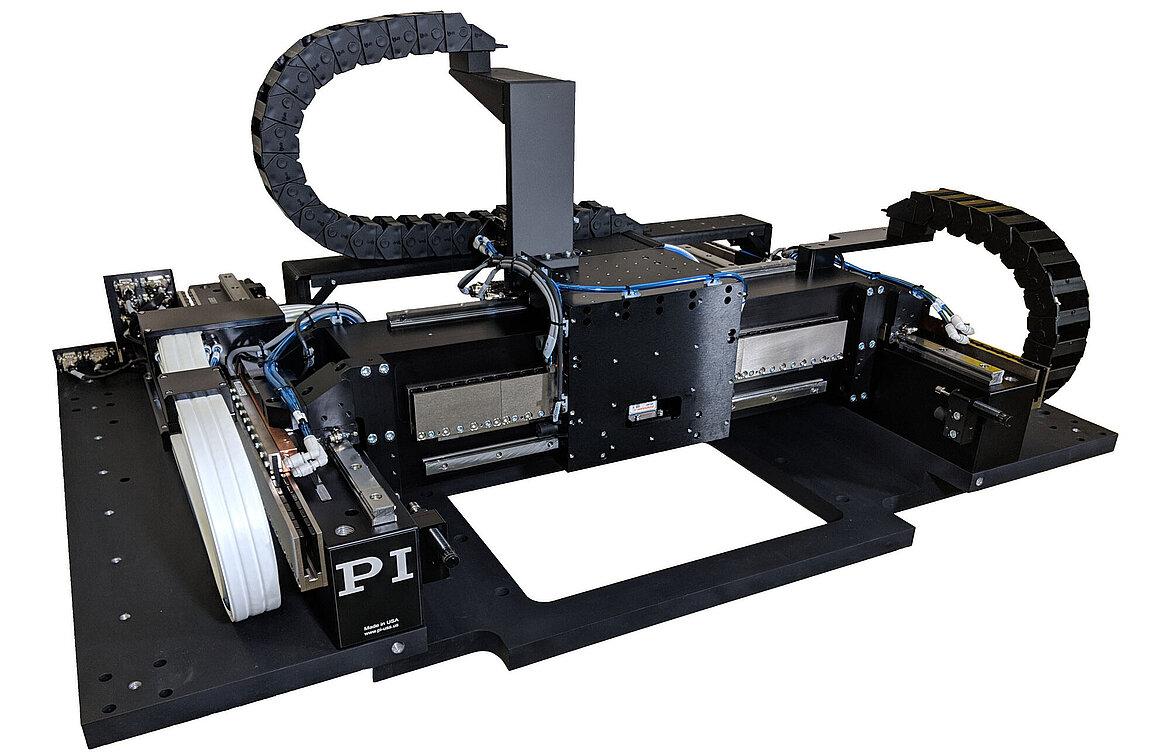

At first glance, a precision gantry automation system may seem like a basic Cartesian setup: a few axes stacked over a work envelope. But once nanometer precision, micron-level repeatability, and 24/7 uptime are on the table, the reality gets far more complex. Here’s a look at the biggest engineering hurdles — and why experienced system-level design is essential.

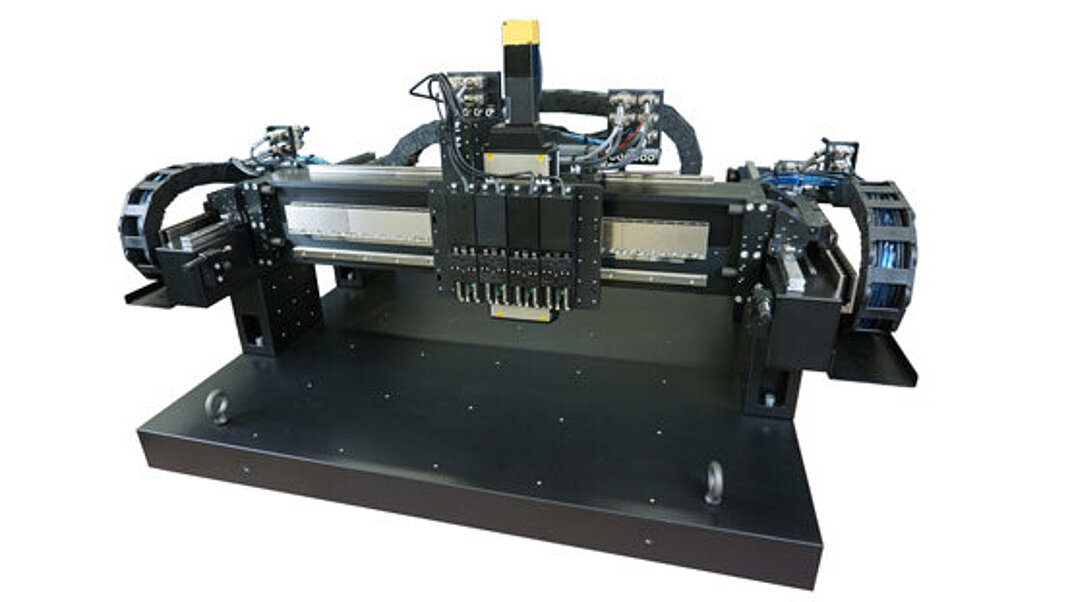

1. Staying Rigid Across the Span

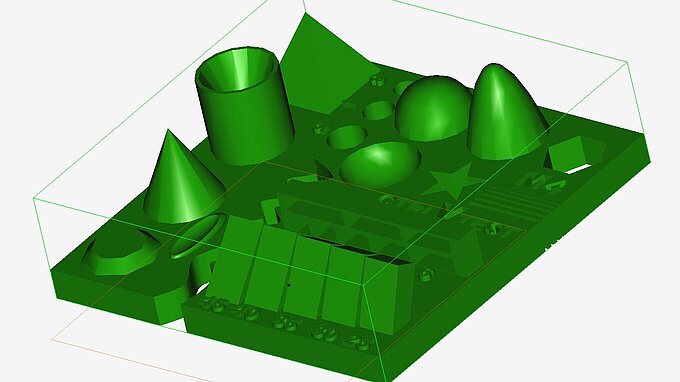

The longer the bridge, the more it wants to flex. Maintaining stiffness without adding excessive mass is a delicate balancing act. Add too much weight and you compromise dynamics; too little and precision falls apart. That’s why companies like PI invest heavily in FEA simulation and draw from decades of experience to optimize every gram of structure for rigidity without sacrificing responsiveness.

2. Thermal Drift is the Silent Precision Killer

In general automation, a few degrees of temperature variation isn’t a big deal. But in precision systems, thermal expansion across long axes can create over-constrained conditions — sometimes even causing mechanical lock-up. More often, it increases bearing loads and shortens their lifespan. Knowing how to design for thermal decoupling and compliance is critical for long-term reliability and accuracy.

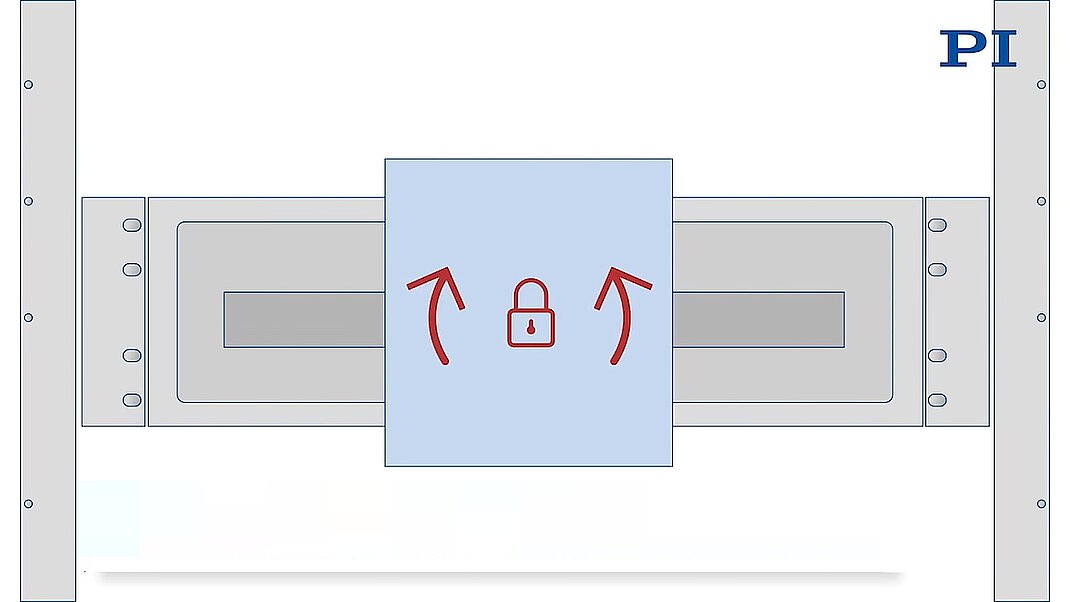

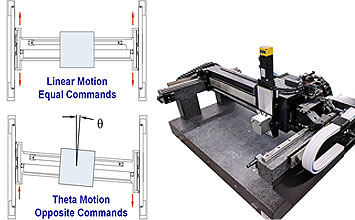

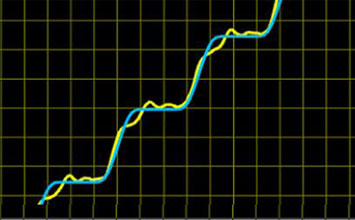

3. Gantry Motion Control and Dual Drive Sync: Racking is Real

When a gantry bridge is driven from both sides, even minor mismatches between motors — mechanical or electrical — can cause racking. This twisting motion introduces angular errors and can compromise part quality. A capable motion controller helps but knowing which features (like gantry alignment loops or torque following) to activate — and when —is where many teams struggle.

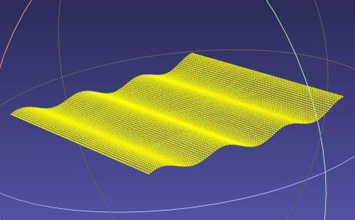

4. Heavy and Fast Don’t Mix Easily

High payloads and long bridge spans moving quickly generate enormous inertia, leading to position overshoot, long settling times, and dynamic instability. This instability directly undermines constant velocity, which is critical for many manufacturing and metrology processes where speed fluctuations translate to process errors. Designing with sufficient margin is non-negotiable to ensure stable, uniform motion under real-world conditions. The gantry has to perform not just under ideal conditions, but in the messy realities of production — where small issues like cable snags or unexpected payload shifts can compound quickly. Advanced motion control algorithms, such as PILOT, virtually increase the motor constant, allowing for higher performance, while reducing motor current and thermal load.

5. Assembly Tolerances Are Critical

It’s not just the design — it’s the execution. Every mating surface in a gantry system must be flat, orthogonal, coplanar, and precisely aligned. Iterative alignment isn't scalable in volume production, especially when you're up against tight delivery deadlines. Precision must be built in from the ground up — starting with the frame.

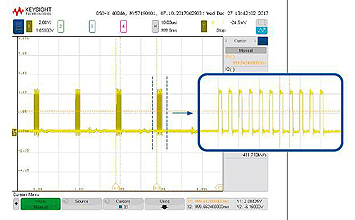

6. Position-Based Event Synchronization

Processes like laser firing, image capture, or part placement must happen at exact positions — not just when the stage thinks it’s there. With long travel ranges, mechanical flex, and loop delays, achieving rock-solid event synchronization is tougher than it looks. Hardware-timed outputs tied directly to encoder feedback are a must to avoid image blur, part misplacement, or delayed process triggers.

7. Cable Management: The Hidden Variable

Cables and hoses might seem like an afterthought, but they often introduce unpredictable forces that affect repeatability and tuning. There’s no one-size-fits-all rulebook for managing drag chains in high-dynamic precision systems. Experience is key — understanding how even subtle cable-induced torques impact performance separates functional systems from exceptional ones. In critical applications, a second motorized system can be added to reduce friction. Also, for clean-room applications special cable management solutions are available.

The Bottom Line: It’s a System, Not Just a Stack of Components

Thinking of building your own precision gantry? Be warned: the margin for error is razor-thin, and the number of things that can go wrong adds up fast.

Success takes more than quality components. It requires deep system-level expertise — understanding how mechanical design, thermal behavior, control algorithms, cable dynamics, and real-world process variables all interact.

That’s where PI stands apart. With decades of real-world application experience, simulation-driven engineering, and integrated motion control, PI delivers precision gantry systems that work the first time — and keep working long after.

Ready to build a gantry that meets the spec — and reality?

Talk to an expert at PI. We’ll help you avoid the traps and deliver the precision your process demands.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy