PI’s hexapod (Stewart platform) controllers for high accuracy motion and positioning deliver reliable precision in demanding industrial and research environments. By coordinating six degrees of freedom with sub-micron to nanometer-level motion resolution, our advanced parallel-kinematics hexapod controllers enable precise alignment, scanning, and manipulation where conventional serial-kinematics stages fall short. Engineered to integrate seamlessly with PI hexapods, each motion controller automatically performs coordinate transformation and multi-axis path planning in real-time. The integrated models handle the advanced kinematics, and the robust calibration and tuning allows users to achieve consistent, repeatable results across complex motion profiles. Whether you are looking at high-load positioning with smooth, constant velocity, or high-speed motion simulation with our direct-drive hexapods, PI’s hexapod controllers deliver proven performance.

How Do Hexapods Work?

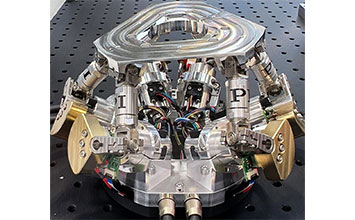

Hexapods leverage parallel-kinematic mechanics—six actuators working in concert—to produce smooth, coordinated motion in X, Y, Z, pitch, roll, and yaw. This architecture minimizes cumulative errors, reduces moving mass (inertia), and enhances stiffness, directly improving accuracy and dynamic responsiveness, critical in wafer positioning, optical component alignment, micro-assembly, and metrology. PI’s 4th-generation hexapod controllers are purpose built advanced machines–based on 4 decades on in-house hexapod design and development–and ensure that the hexapod operates at peak performance across different applications.

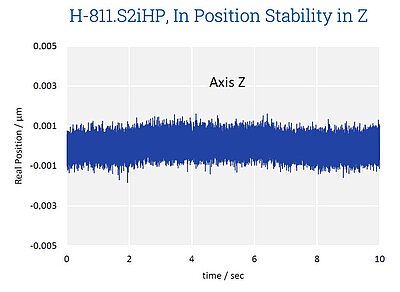

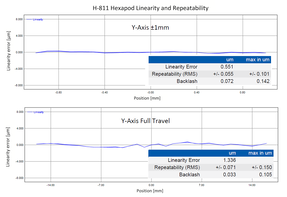

PI hexapods and controllers achieve sub-micrometer accuracy by combining high-resolution encoders, model-based kinematics, and feedforward/feedback control loops tuned to the mechanical structure. Vector motion control coordinates multi-axis moves along defined paths in Cartesian space, improving path accuracy and reducing cross-axis coupling in complex scans and real-time trajectory planning ensures synchronized motion across all axes.

Hexapod Control and Simulation Software

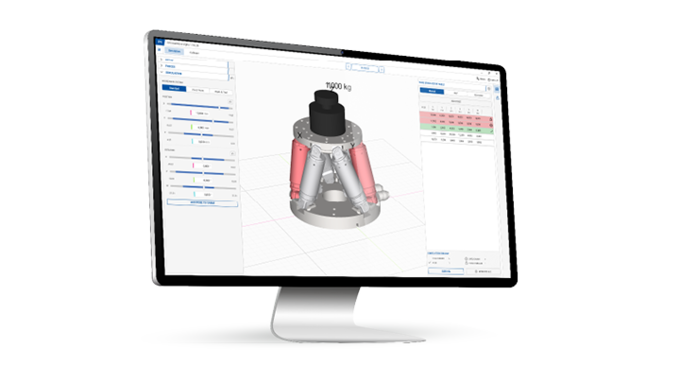

Hexapod control software enables automated hexapod parametrization, the visualization of the positions of all actuators, and execution of macro programs. A data recorder is available to analyze system behavior.

Simulation software enables customers to simulate motion and test different use-cases before receiving the actual hardware.

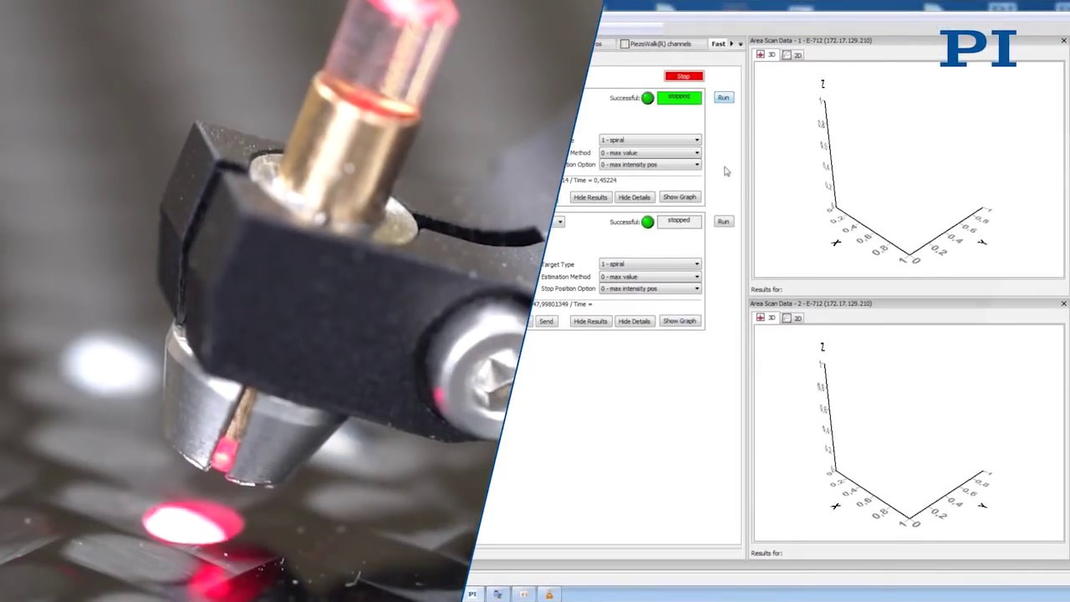

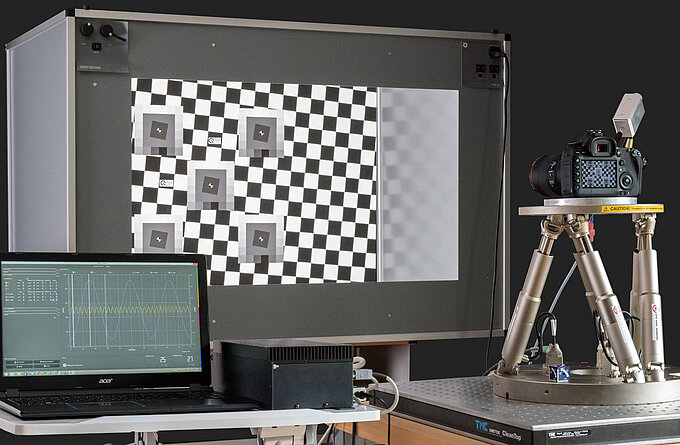

Specialized, integrated scan and alignment routines provide significantly higher throughput and performance in advanced optical and photonics alignment applications compared to external software-driven setups.

Innovative Features of PI Hexapod Controllers

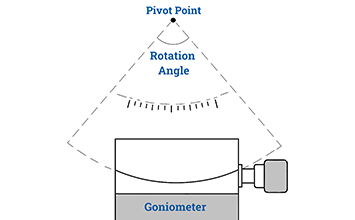

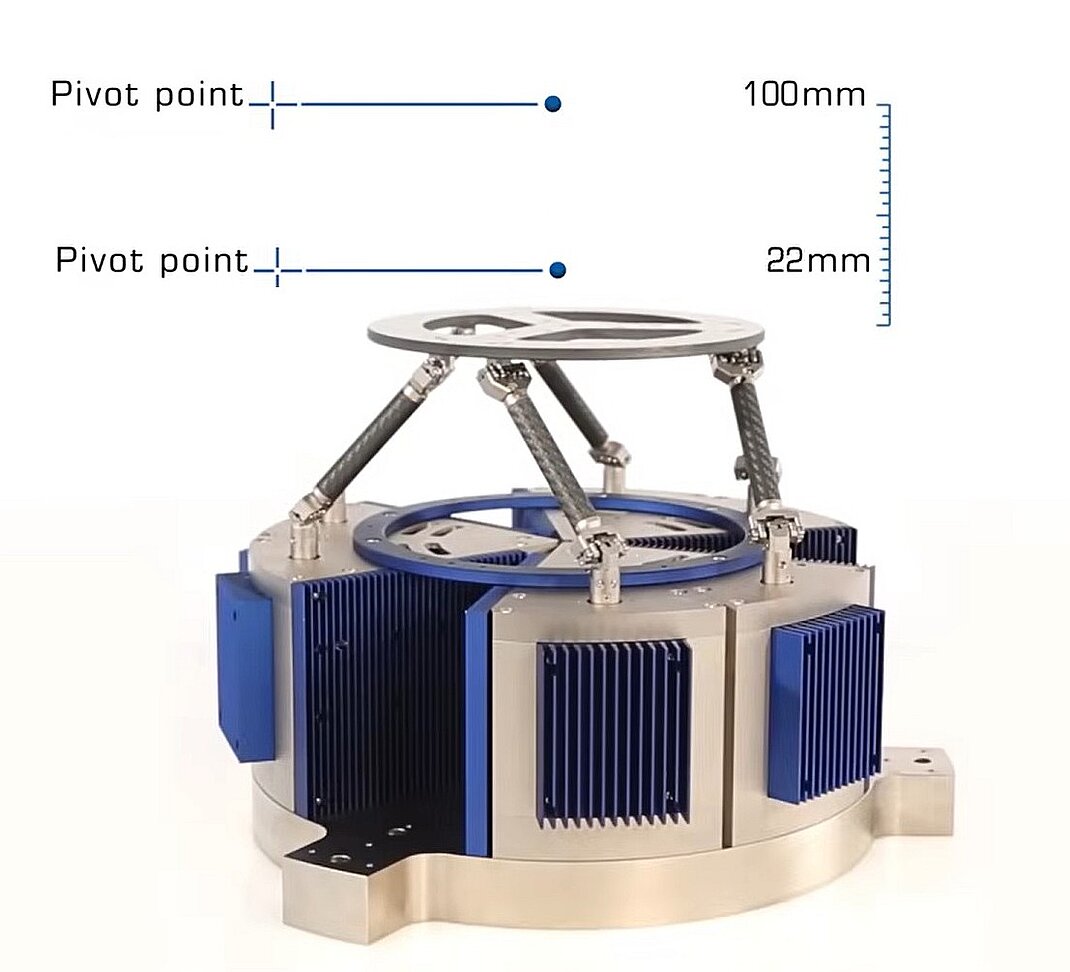

User-defined center of rotation: PI hexapod controllers allow the user to program its virtual pivot point anywhere inside or outside the hexapod’s working envelope—a critical feature for improving alignment precision while reducing cycle time.

Application-ready routines expand capability: Built-in scan and alignment routines for optics and photonics streamline tasks such as fiber alignment and lens centering. A high-bandwidth analog input (important with use of high-speed optical power meters) allows users to run spiral and raster, scans, for device characterization, with synchronized power and position acquisition.

All of these routines are accessible through PI’s hexapod control software, making automated hexapod control straightforward for factories and research labs.

Integration is streamlined with PI software tools and APIs for Python, C/C++, LabVIEW, and MATLAB, plus TCP/IP and a real-time EtherCAT option. Features include embedded diagnostics and health monitoring for maintenance, and seamless handoff between manual jog and automated routines without losing registration—ideal for hexapods in precision manufacturing.

Comprehensive Specifications and Technical Data

PI offers standard and custom hexapod controllers for to compact, medium, and high-load hexapods. Core specifications include nanometer-level command resolution, multi-kHz servo update rates, and coordinated 6-DOF trajectory control with vector motion control for accurate path following. System-level linear and angular accuracy is validated through factory calibration, ensuring that each hexapod and motion controller pair achieves documented performance.

In addition to the coordinated output of the six hexapod axes, standard motion controllers provide two additional axes that can be used to operate rotary stages, linear stages or linear actuators.

Performance metrics vary by model and application: load capacity ranges from miniature-optics-scale payloads to heavy instrumentation; repeatability reaches sub-micrometer levels for linear axes and arcsecond-level for angular axes; travel ranges are balanced for precision and workspace requirements. A programmable pivot point ensures consistent rotation about user-defined centers, critical for precision optics and photonics alignment. These capabilities are supported by advanced hexapod controllers and intuitive hexapod control software.

Industrial durability is built in. Controllers feature robust thermal management, EMI-resistant designs, and redundant safety functions (soft limits, watchdogs, fault handling). Hexapods are available with absolute-measuring encoders and integrated brakes, ensuring safety and consistent performance in 24/7 environments such as semiconductor fabs and precision optical production.

Software Components / External Control

- Library files for Windows and Linux Operating Systems / DLLs

- LabView VI’s full set

- PIMikroMove program integration

- Additional scan routines

- Additional auto alignment routines (e.g. photonics alignment & test equipment)

- Worldwide remote control via ethernet

- Flight Simulator Interface with Demo Software

Frequently Asked Questions

How do PI hexapods and controllers achieve high accuracy motion?

They combine parallel-kinematic mechanics with high-resolution feedback, real-time inverse kinematics, vector motion control, and tightly tuned control loops. A programmable pivot point ensures accurate rotations about defined centers, enhancing precision and reducing alignment time.

What factors affect the performance of hexapods?

Key factors include mechanical design of the drivetrain, joints, mechanical stiffness and actuator linearity, encoder type and resolution, control loop bandwidth and tuning, environmental stability (temperature, vibration), payload mass and center of gravity, cabling and grounding, and the quality of trajectory generation. Proper integration, calibration, and application-specific configuration—including the use of specific hexapod control software—are essential for achieving specified accuracy and repeatability with a motion controller and hexapod.

Custom Hexapod Controllers

In addition to the standard hexapod controllers / software packages, PI has also designed a number of controllers for customer specific applications.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy