A precision linear stage, or linear translation stage is a positioning device providing linear motion with high accuracy and minimized runout errors. Motorized linear translation stages with high resolution and motion fidelity are critical to the success of industrial and scientific applications from beamline systems to semiconductor manufacturing and photonics instrumentation.

From Cost-Effective to Ultra High-Performance Linear Translation Stages

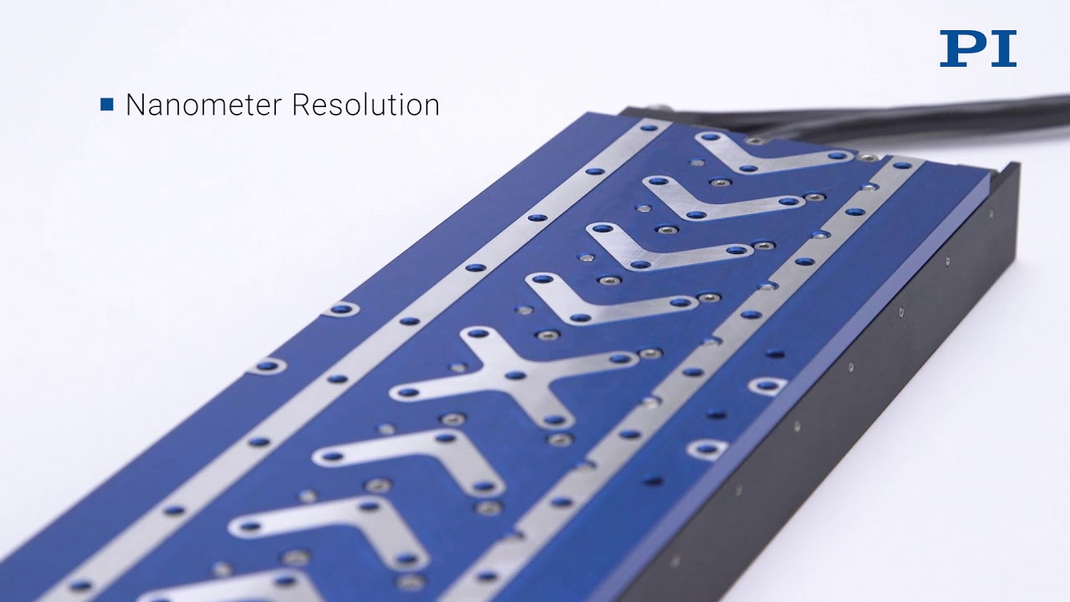

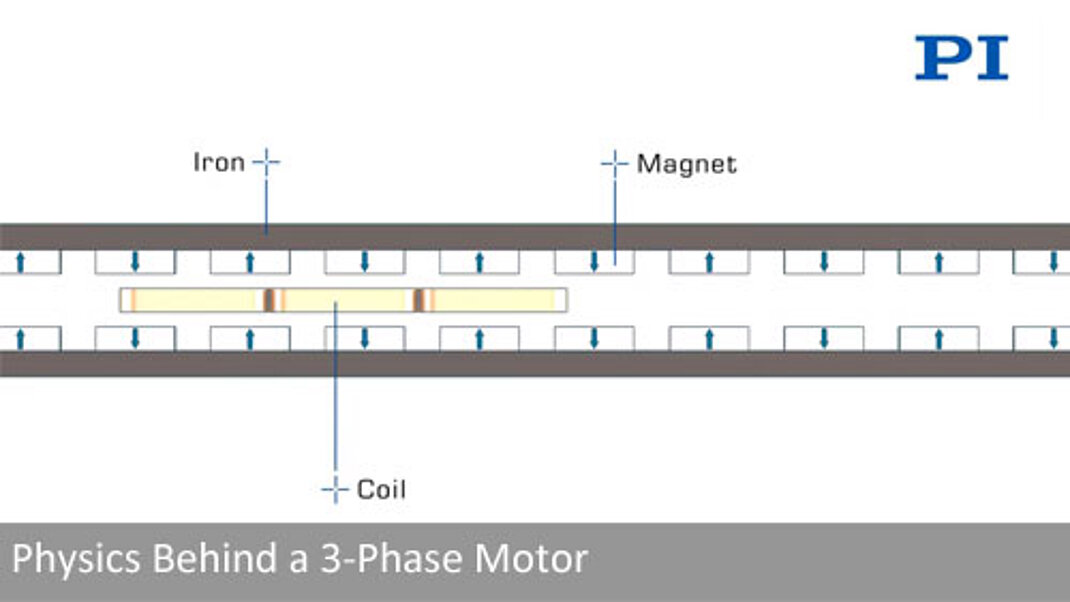

Linear stage designs vary from low cost, stepper-motor-driven positioning and indexing tables, to closed-loop motorized linear stages with linear encoders for direct position feedback and the highest positioning accuracy. Modern linear encoders achieve nanometer resolution and better. When the highest performance, speed and the best velocity control are required, electromagnetic, direct drive linear motors are recommended. The direct-drive principle increases overall performance and eliminates friction, wear and losses that occur when rotation is converted to linear motion.

For the highest geometric and positioning performance over longer travel ranges, direct drive linear translation stages with air bearings are available.

Air Bearing Linear Stages for the Highest Performance Requirements

When the highest precision is required, Air Bearing Linear Stages are recommended. PI USA provides air bearing linear and rotary stages based on over 200 years of in-house air bearing experience.

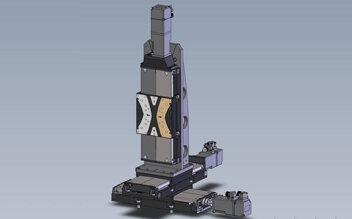

Vertical and Multi-Axis Motion

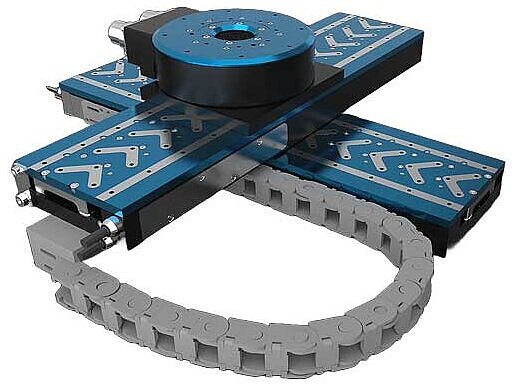

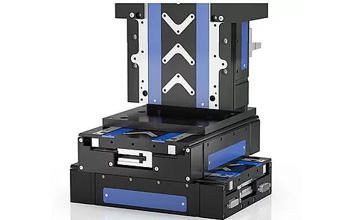

In addition to the linear translation stages shown on this page, vertical (lift) positioners as well as XY-systems and multi-axis stages, for high-precision motion applications are also available.

Vacuum, too

As a specialist for vacuum motion systems, PI miCos also offers HV and UHV vacuum compatible linear positioning stages.

Low-Cost Precision Lead / Ball Screw Stages w/ Stepper & Servo Motors

<0.2 to 0.5µm Resolution, Travel to 300mm, 10mm/sec to 100mm/sec

Classical motorized linear stages, with ball bearings or crossed roller bearings and leadscrew drives.

Lead-screws provide high forces and self locking capabilities while ball screws are used for higher speed applications with longer service life. Position feedback is available with motor shaft mounted rotary encoders.

Direct-drive stepper motors or servo-motor wit gearbox are mostly used to drive the stages.

L-836 Low-Cost Stepper Motor Stages

Ball Screw, Encoder Option, Multi-Axis Configuration

25/50/75/100/150/200mm travel

0.24-0.75µm min. incremental motion

80nm sensor resolution

80mm/sec max. velocity

75N push/pull force

M-403 Low-Cost Linear Stages

Leadscrew, Servo Motors

25/50/100/150/200mm travel

- 0.25µm min. incremental motion

- 20-250nm sensor resolution

- 2-10mm/sec max. velocity

- 50N push/pull force

- Direct-drive & gearbox motors

M-414 Linear Stages

Ballscrew, Servo Motors, High Load

- 100/200/300mm travel

- 0.1-0.5µm min. incremental motion

- 100-500nm sensor resolution

- 3-100mm/sec max. velocity

- 100N push/pull force

- Direct-drive & gearbox motors

Compact Direct-Drive Stages, High Accuracy, w/ 3-Phase & VC Motors

<1 to 20nm Resolution, up to 1.5m/sec

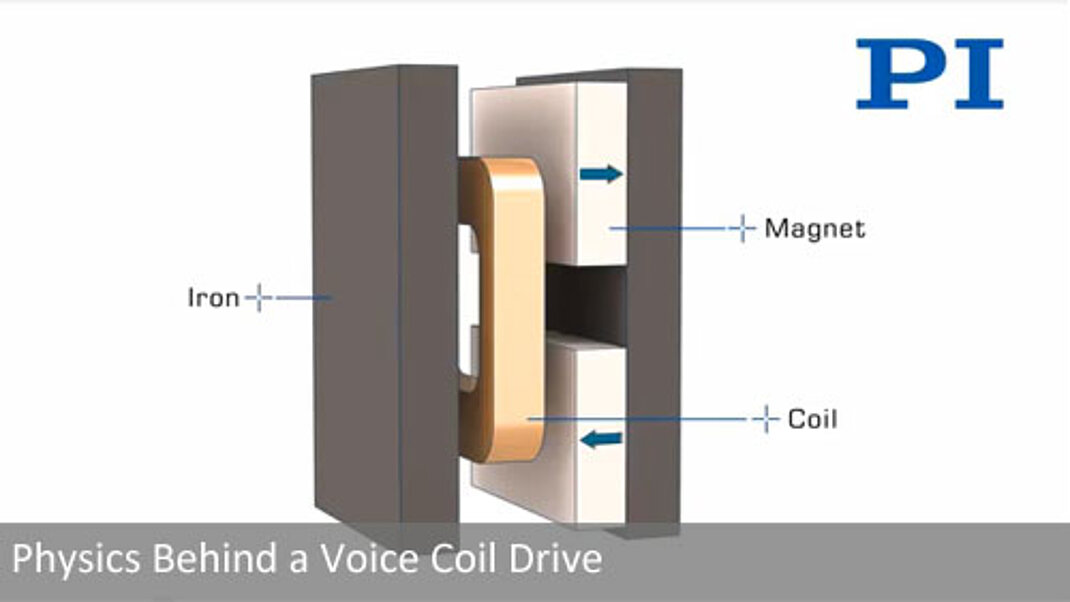

These linear motor stages provide very high speed and very long lifetime. They are ideal for precision automation applications. Frictionless 3-phase motors and voice coil motors provide the driving force. Crossed roller bearings provide excellent straightness and flatness with minimized runout. Position feedback is provided by linear encoders with sine/cosine output or optional absolute encoders (no need for homing).

V-141 Low-Cost Linear Motor Stage

Compact, High Force, 80mm Width

40, 60, and 100mm travel

120nm bidirectional repeatability

2µm accuracy

1m/sec max. velocity

Up to 45N push/pull force

V-571 Compact Linear Motor Stage

95mm Stage Width

- 25/50/75/100mm travel

- 1µm straightness/100mm

- 120nm bidirectional repeatability

- 1nm absolute encoder resolution

- 0.5m/sec max. velocity

- 21N push/pull force

V-508 Linear Motor Stage

Compact, High End Sensor Option

- 170/250mm travel

- 1 to 20nm min. inc. motion

- 0.2-10nm linear encoder resolution

- 0.7m/sec max. velocity

- 14N push/pull force

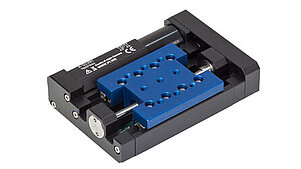

Compact Motorized Positioning Stages with Servo & Stepper Motors

to 25mm Travel, 1µm to 0.05µm Resolution, to 5mm/sec

The most economical drives are usually loop stepper motors, while closed-loop motors with encoders for position feedback provide higher precision.

The M-110/M-111/M-112 family of motorized linear stages provides a space-saving design with a folded drive train featuring the motor side-by-side with the moving platform. Leadscrew and ball screw versions with both servo an stepper motors are available.

The M-505 and M-122 linear stages provide the highest precision by means of an integrated linear encoder.

M-110/1/2 Miniature Stages

Lead/Ballscrew, Servo & Stepper

- 5/15/25mm travel

- 0.05µm min. incremental motion

- 7nm sensor resolution

- 1-2mm/sec max. velocity

- 10N push/pull force

- DC & stepper gearbox motors

L-505 Miniature Stages

Linear Encoder to 5nm

- 13/26mm travel

- 0.05-1µm min. incremental motion

- 5nm & 50nm linear encoder resolution

- 1-15mm/sec max. velocity

- 20-65N push/pull force

- DC & stepper motors

M-122 Miniature Stages

Linear Encoder, Ballscrew

- 25mm travel

- 0.1µm linear encoder

- 20mm/sec max. velocity

- 20N push/pull force

- DC motor

Ultra-Compact Piezo Motor Driven Stages with High Accuracy

to 52mm Travel, to 0.5nm Resolution, to 10mm/sec

Piezo motors allow for smaller stage designs. They create no magnetic fields and are not influenced by magnetic fields. On power off, these motors are self-clamping, holding a position without drift, and energy consumption. Two types of motors are shown below:

Inertia Linear Motors

Inertia motors are extremely compact and offer the best ratio of size, precision and cost, with relatively simple controller design.

PiezoWalk® Linear Motors - higher force & precision, for high-end applications

PiezoWalk® technology, combines piezo class resolution with long travel ranges, sub-nanometer resolution, high forces and stiffness, these piezo stepping drives are not subject to sliding friction or wear as motion is achieved when the “legs” lift off for each step. Designed for high-end applications in bio-nanotechnology, fiber-optics, microscopy, semiconductor testing, and metrology and scientific research in beamlines and laser labs.

B-421 Sub-Miniature Linear Stage

Bi-Phase Piezo Inertia Direct Drive

- 13, 23, 32mm motion range

- 6nm sensor resolution

- 14mm/sec velocity

- 29mm width, 11mm height

- Self-clamping motor, 3N

Q-545 Piezo Inertia Motor Stage

Compact, X, XY, XYZ

- 13/26mm travel

- 6nm min. incremental motion

- 1nm sensor resolution

- 10mm/sec max. velocity

- 8N push/pull force

- Low cost, piezo inertia motor

N-565 PiezoWalk® Motor Stage

Ultra-High Precision

- 13/26/52mm travel

- 0.5nm linear encoder

- 10mm/sec max. velocity

- 10N push/pull force

- For high end applications

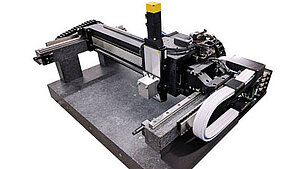

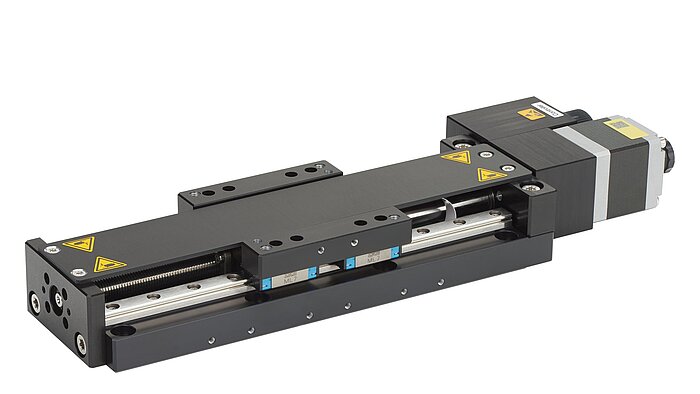

Precision Ball Screw Stages with Stepper & Servo Motors

<0.2 to 0.5µm Resolution, Travel to 300mm, 10mm/sec to 100mm/sec

These precision motorized linear stages are equipped with crossed roller bearings for excellent straightness and flatness with minimized runout. They are driven by ballscrews, with stepper and servo motors, and come with optional linear encoders for better precision. Multi-axis systems are easily assembled, and PI also offers custom brackets was well as enhanced orthogonality.

Motion Controllers

A variety of controllers are available, from simple, very compact and economical single axis designs to automation grade multi-axis units based on ACS hardware with Ethercat® interface.

L-509 Precision Linear Stage Family

Ballscrew, Linear Encoder Option

- 1/2/4” travel

- 0.01 to 0.2µm min. inc. motion

- 1 to 50nm sensor resolution

- 3-50mm/sec max. velocity

- 60N push/pull force, 100N load

- Linear encoder option

L-511 Precision Linear Stage Family

Ballscrew, Linear Encoder Option

- 2/4/6” travel

- 0.02 to 0.2µm min. inc. motion

- 1 to 60nm sensor resolution

- 6-90mm/sec max. velocity

- 100N push/pull force

- Linear encoder option

These high-performance, motorized linear stages are designed for high forces and long travel ranges in industrial applications. They are driven by ball screws, and synchronous motors, stepper motors, and servo motors and most are available with linear encoders for the highest precision requirements. Fully aligned and tuned multi-axis stage systems are also available.

L-812 High Load Linear Module

Cost Effective, Servo & Stepper Motor

- 114 - 610mm (4.5”-24”) travel

- 3µm min. inc. motion

- 5µm bidirectional repeatability

- 100mm/sec max. velocity

- 377N push/pull force

- Absolute encoder option

L-417 High Load Linear Stage

Ball Screw Drive, 450N Load

- 102 - 813mm (4”-32”) travel

- 0.05µm to 1µm min. inc. motion

- 1nm to 600nm encoder res.

- 350mm/sec max. velocity

- 700N push/pull force

- Linear encoder option

LS-180 Linear Stage

Long Travel to 508mm

- 155/205/305/508mm travel

- 0.1 to 0.5µm min. inc. motion

- 5 to 50nm encoder res.

- 75 to 150mm/sec max. velocity

- 800N push/pull force

- Linear encoder option

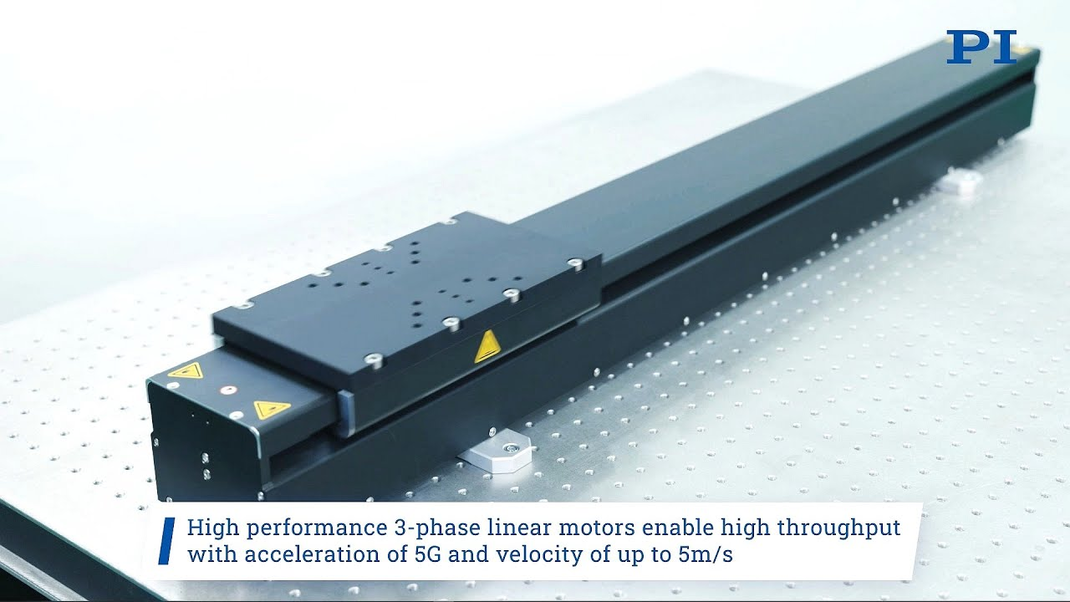

Linear Motor Stages w/ High Accuracy / Long Travel / High Load

0.2 to 40nm Resolution, up to 1000mm Travel

V-572 Linear Motor Stage

130mm Stage Width

- 60/110/150/210mm travel

- 0.8 - 1.5µm straightness

- 160nm bidirectional repeatability

- 1nm absolute encoder resolution

- 0.5m/sec max. velocity

- 60N push/pull force

V-574 Linear Motor Stage

160mm Stage Width

- 1 - 1.5µm straightness

- 60/130/230mm travel

- 80nm bidirectional repeatability

- 1nm absolute encoder resolution

- 1m/sec max. velocity

- 58N push/pull force

V-573 Linear Motor Stage

160mm Stage Width

- 1 - 1.75µm straightness

- 160/260/360mm travel

- 80nm bidirectional repeatability

- 1nm absolute encoder resolution

- 500mm/sec max. velocity

- 140N push/pull force

V-417 High Speed Linear Stage

Linear Motor, 450N Load

- 102 - 813mm (4”-32”) travel

- 5nm to 10nm min. inc. motion

- 1nm encoder res.

- 2m/sec max. velocity

- 300N peak force

- Absolute encoder option

V-817 Economical High Performance Stage

Linear Motor, 3m/sec 600N Load

- 204 - 813mm (8”-32”) travel

- 10nm min. inc. motion

- <1nm encoder res.

- 3m/sec max. velocity

- 300N peak force

- Excellent value for precision automation

V-827 Linear Motor Stage

Wide Base, High Load, to 1m Travel

300/500/750/1000mm travel

150nm bidirectional repeatability

1nm absolute encoder res.

2m/sec max. velocity

720N push/pull force

A-141 Miniature Air Bearing Stage

Ultra-Compact Air Bearing Stage

- 40mm travel

- 3.5kg load

- 20nm resolution

- 57x83mm table; 38mm height

- 0.25m/sec max. velocity

- 0.35g max. acceleration

A-110 PIglide Air Bearing Stage

Affordable Design, Travel to 16”

- 2/4/8/12/16” travel

- 10kg load

- 1nm resolution, abs/enc option

- 160x200mm table; 60mm height

- 1m/sec max. velocity

- 2g max. acceleration

A-123 PIglide Air Bearing Stage

Large, Travel to 30”

- 2/4/6/10/14/20/30” travel

- 10kg load

- 1nm resolution, abs/enc option

- 210x210mm table; 85mm height

- 1m/sec max. velocity

- 3g max. acceleration

What is a Motorized Linear Stage?

A motorized linear stage is a device that facilitates automated movement in a straight line. It encompasses bearings which can withstand torques and linear forces perpendicular to the motion direction, thereby allowing it to support a load. Often referred to as linear translation stages or linear slides, they are a crucial component in single-axis and multi-axis motion systems.

Linear Stage Buyers Guide

Consider the following factors when buying a motorized precision linear stage:

- Load Capacity, Stiffness, and Size: Consider the size, mass, and inertia of the object that the linear stage will need to move. A miniature stage might have the right on-center load capacity, but a lengthy, off-centered load could provide too much torque for the bearings to handle. A stage with a higher load capacity will provide a longer lifetime in high duty cycle applications.

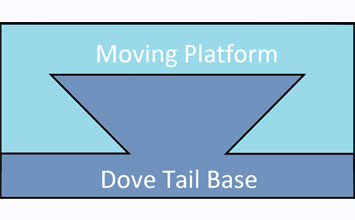

- Bearing Type: In general, cross-roller bearings provide higher load capacity and better geometric performance than ball bearings. Air bearings provide the highest accuracy and lifetime since they are friction-free and maintenance -free.

- Travel Range: This refers to the total distance that the stage can move. When stacking stages for XY applications, consider the bottom stage to have a relatively wide base compared to the travel range of the top stage to reduce bending moments.

- Acceleration and Speed: Higher velocity and acceleration can be achieved with direct-drive stages. Lead-screw or ballscrew driven stages can provide higher force. The motor size and motion control will have a big influence on step-and-settle performance.

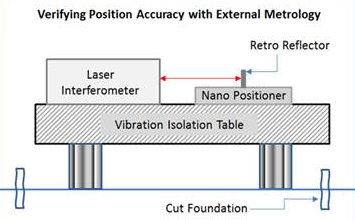

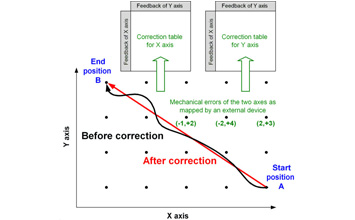

- Accuracy, Repeatability, and Resolution: Stages with linear encoders typically provide higher accuracy and repeatability compared to motor mounted rotary encoders or open loop stepper motors. Linear encoders with nanometer resolution are available today.

- Drive Mechanism: The following drive mechanisms are offered -- lead screws (self locking), ball screws (lower friction than lead screws), linear motors (highest velocity and accuracy, ideal for industrial 24/7 applications), or piezo motors (compact, high resolution, self locking).

- Environment Suitability: For vacuum applications, special designs are necessary. Air bearings are ideal for clean rooms. Special protection is required for harsh industrial environments.

- Support and Warranty: Check the level of technical support provided by the manufacturer, as well as the warranty terms. Always discuss your requirements with a knowledgeable engineer at the manufacturer or supplier to ensure you choose the most suitable stage for your application.