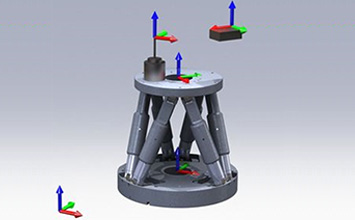

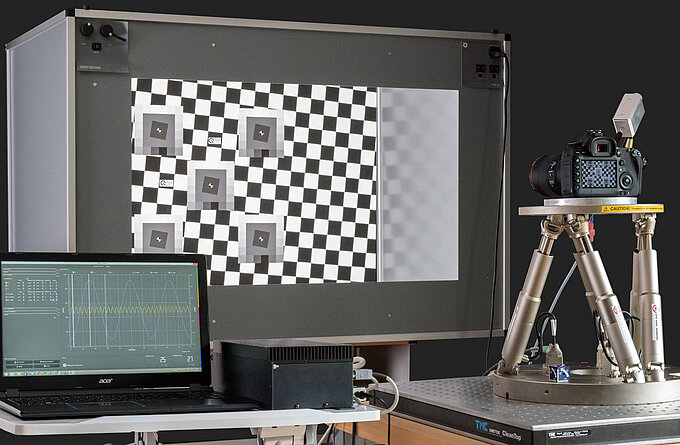

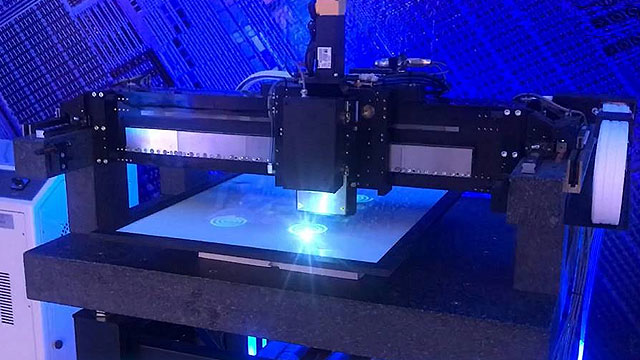

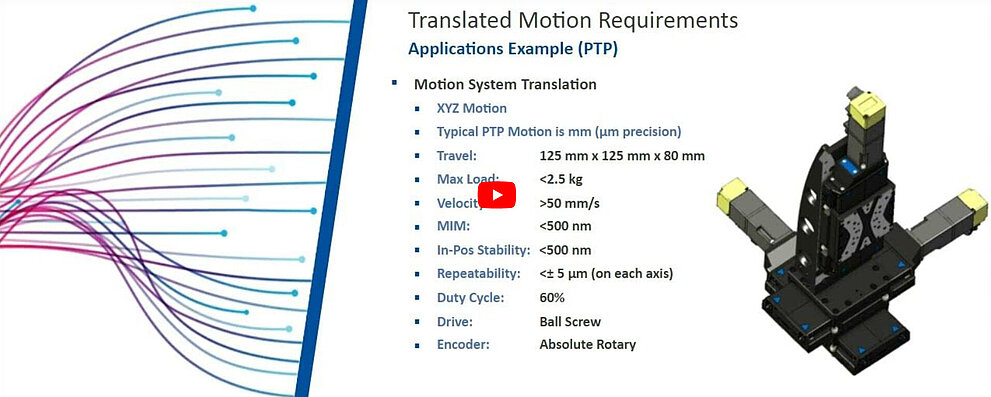

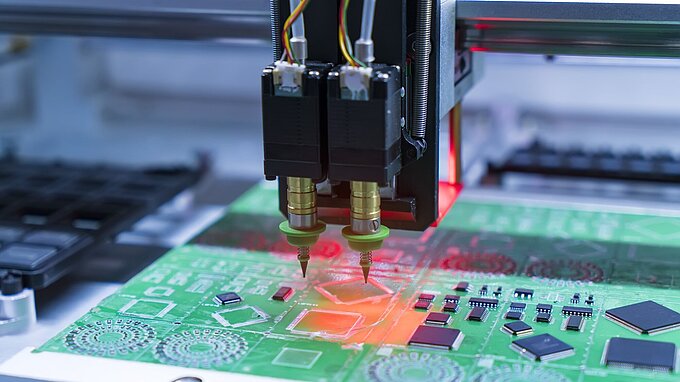

Precision motion stages and hexapods dance across microns and nanometers, improving semiconductor metrology, photonics component test and assembly, PCB manufacturing, medical device manufacturing and many other intricate tasks. In the world of precision automation, these highly specialized positioning stages are the silent conductors, ensuring accuracy and efficiency down to the smallest detail.

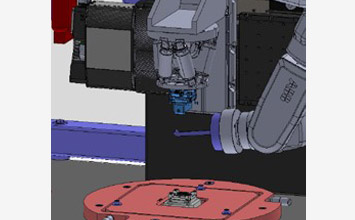

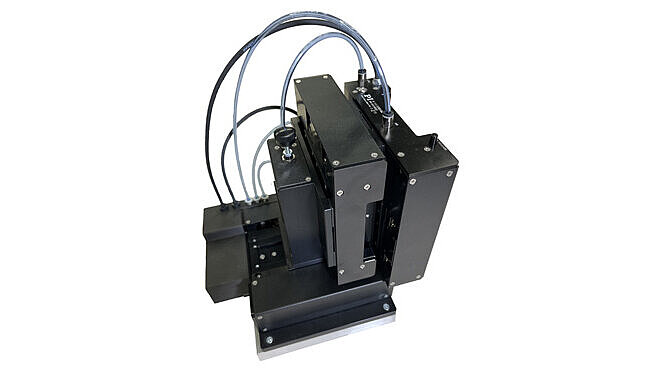

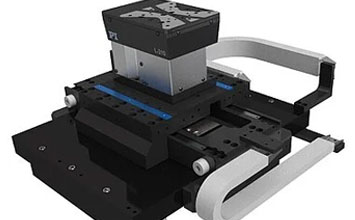

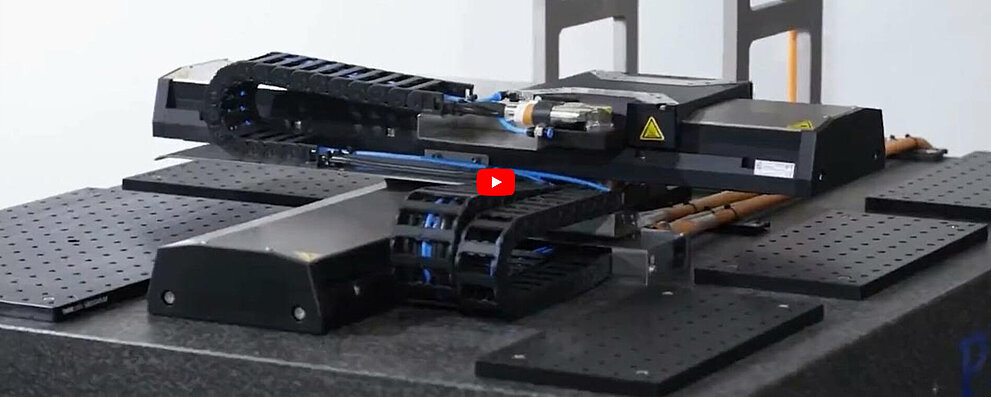

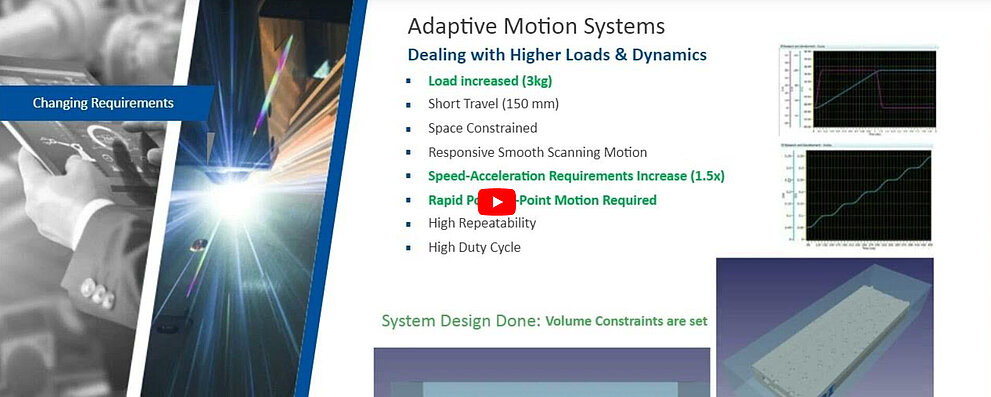

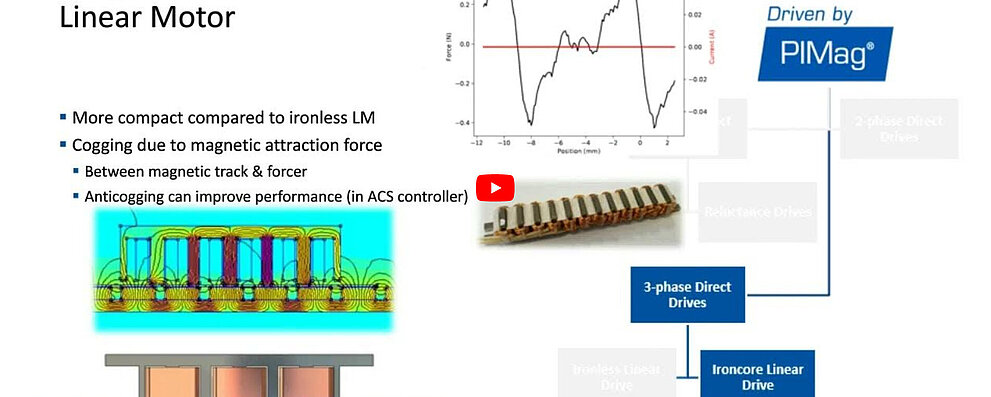

The precision motion systems in the applications below rely on precision mechanics — either with mechanical bearings or completely friction-free air bearings — and highly advanced motion controllers and algorithms.

Piezo transducers can convert electricity into motion and pressure changes into electricity. Piezo transducers are used to control dispensing valves with incredible precision, enabling droplet volumes down to nano- and pico-liters critical for applications such as coating or digital printing. Additionally, they have the capability to sense pressure, ensuring the seamless handling of materials, and can measure flow without any physical contact or interference with the liquid or gas being assessed. As ultrasonic ears, they detect flaws in welds and cracks in machinery. From auto assembly to microfluidics, these versatile tools orchestrate the symphony of industrial automation, driving efficiency and quality.