Providing precision positioning equipment for a vacuum environment follows clearly defined conditions. First, contamination of the vacuum chamber with particles through abrasion or outgassing but also through excessive heat input must be avoided. In addition, the installation space is usually limited. PI has many years of experience in vacuum technology and applications as well as a high vertical range of manufacturing. Therefore, PI is able to offer standard and customized products that are precisely tailored to the requirements of the vacuum application, e.g. by appropriate drive components, material selection, design, and accessories as well as suitable manufacturing processes and quality control.

Positioning Solutions for Vacuum Environments

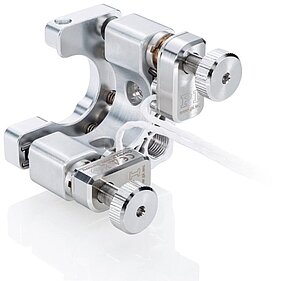

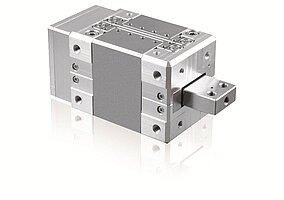

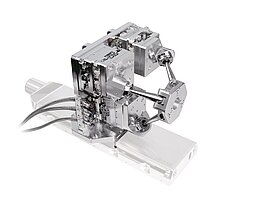

PI offers various motion technologies that are suitable for vacuum applications: This includes piezo actuators, which can also work in strong magnetic fields and cryogenic environment, piezo systems with travel ranges of less than 1.5 mm and subnanometer precision, piezo motors in different designs with respect to force, dynamics, and travel range, motorized positioners with specially designed DC or stepper motors that allow larger travel ranges as well as parallel kinematic hexapods for positioning in six degrees of freedom.

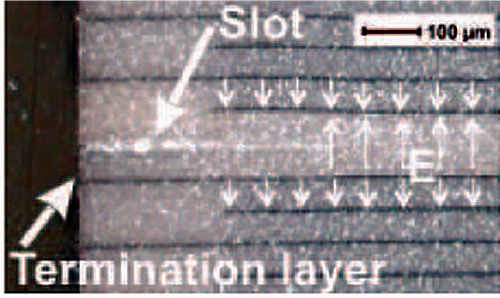

PI offers a wide range of products that have been developed on the basis of >> piezo actuators. Piezo actuators do not require lubricants or cause abrasion. Their motion is based on the >> piezo effect, and is therefore wear free. As the piezo effect is based on electric fields, piezo actuators neither generate nor are they affected by magnetic fields. The piezo effect exists even at lowest temperatures close to 0 Kelvin. In addition, piezo ceramics are insensitive to high-energy radiation. The >> PICMA® all-ceramic isolated actuators do not require polymer insulation and provide the optimum conditions for use in ultrahigh vacuum: no outgassing and high bakeout temperatures of up to 150 °C.

The high stiffness of piezo actuators enables high force generation and dynamics. Their rapid response time in the microsecond range is a result of their high resonant frequency of several hundred kilohertz. The travel ranges of piezo actuators are typically in between a few 10 to a few 100 μm for linear actuators. Bending actuators can achieve a few millimeters. Piezo actuators reach subnanometer resolution.

Depending on the configuration and control, piezoceramic actuators can be used for translational, rotational, or tilting motion, or they can be used as motors in just as many configurations. The choice of the drive principle depends on the required travel ranges, forces, resolution, and velocities of the respective application. Next to the drive type, the selection of suitable materials and additional components is decisive for the use of piezo-based positioning systems in a vacuum. For this reason, vacuum-suitable housings, position sensors, and guide systems such as >> capacitive sensors or >> flexure guides are selected. In addition, piezo motors also do not require lubricants or greases for operation.

Regardless of the drive principle, all >> piezomotors can be used in a vacuum and are the drive of choice, especially when travel ranges in the millimeter range are required.

PI offers specific vacuum-ready standard products for selected product series that are already suitable for high vacuum (HV) or ultrahigh vacuum (UHV). Furthermore, most PI products can be modified on request for use in a vacuum. The products provided by PI achieve atmospheric pressure down to 10-9 hPa. In some cases, 10-10 hPa can be reached.

Table 1 shows the different measures taken to achieve the corresponding vacuum class.

| Vacuum class | Motor | Measuring system | Material | Cable and connectors | Guides and spindles | Venting | Bakeout temperature |

|---|---|---|---|---|---|---|---|

| to 10-6 hPa | Greased motor | Standard measuring system | Anodized aluminum components; brass allowed; plastics allowed | 2 m PTFE cable with standard connector | Guides and spindles with vacuum grease | Partly with cannulated screws | Bakeout temperature max. 80°C |

| to 10-7 hPa | HV Motor | HV measuring system | Aluminum, blank; brass allowed; selected plastics | 2 m PI or PTFE cable with UHV connector | Guide and spindle made of stainless steel with vacuum grease | Cannulated screws | Bakeout temperature max. 80°C |

| to 10-9 hPa | Special UHV motor with temperature sensor | UHV measuring system | Aluminum, blank; brass not allowed; no plastic except PEEK or polyimide | 2 m PI cable with UHV connector | Guide and spindle made of stainless steel with vacuum grease | Cannulated screws | Bakeout temperature max. 120°C with/ 150°C without measuring system |

Tab. 1: Different measures taken to achieve the corresponding vacuum class of motorized positioners.

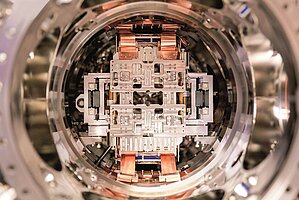

Hexapod platforms are used for precision positioning and alignment of loads in all six degrees of freedom, which means three linear axes, and three rotational axes. Hexapods have a >> parallel-kinematic structure, i.e., the motion platform is actuated simultaneously by multiple actuators. In a parallel-kinematic hexapod all drives act on a single motion platform, which results in a much more compact design than possible with stacked systems. Hexapods feature a high stiffness; therefore, they can be mounted in any orientation. As only one platform is moved, the overall moved mass is lower if compared with a stacked or nested positioning system, resulting in lower inertia, and therefore higher dynamics, which is the same for all motion axes.

Depending on their design, hexapods can position loads from several kg up to several tons in any spatial orientation, independently of the mounting orientation and with submicrometer precision. Designed properly, hexapods are suitable for use in vacuum and can be adapted to different vacuum classes using electric motors or piezoelectric drives and vacuum-suitable sensor technology.

To determine the required vacuum class, it is necessary to know the application as well as possible. For example, EUV lithography, the production of microelectronic circuits, or material analysis using SEM (scanning electron microscopy) place different demands on the pressure range, but also on the permissible residual materials in the vacuum chamber. Therefore, the outgassing rate is another relevant specification. Often the partial pressure of HCs (hydrocarbons) is decisive. Because it determines the pressure in the system (together with the capacity of the vacuum pump), outgassing prohibits fast achievement of low pressure values. In addition, the outgassing compounds may deposit on surfaces of optical elements or other sensitive devices and can obscure or damage them. Therefore, the residual gas must contain very little or no HCs and no metals with high vapor pressure such as zinc, lead, or cadmium.

Vacuum is the state of a gas, when in the pressure of the gas in a container and thus the particle count density is lower than outside or if the pressure of the gas is lower than 300 mbar, i.e. smaller than the lowest one on the atmospheric pressure on the Earth's surface {DIN 28400}. It is measured in either [hPa], [mbar] or [Torr]. Different levels of vacuum classes are defined: Rough, fine, high, ultrahigh, and extremely-high (shown in Tab. 2). PI offers standard products for selected product series that are already suitable for HV or UHV conditions. Furthermore, most PI products can be modified on request for use in a vacuum. The products provided by PI achieve a pressure down to 10-9 hPa. In some cases, 10-12 hPa can be reached.

| Vacuum class | Abbr. | hPa | mbar | Torr |

|---|---|---|---|---|

| Rough vacuum | RV | 300 to 1 | 300 to 1 | 225 to 0.75 |

| Fine vacuum | FV | <1 to 10-3 | <1 to 10-3 | <0.75 to 7.5 × 10-4 |

| High vacuum | HV | <10-3 to 10-7 | <10-3 to 10-7 | <7.5 × 10-4 to 7.5 × 10-8 |

| Ultrahigh vacuum | UHV | <10-7 to 10-12 | <10-7 to 10-12 | <7.5 × 10-8 to 7.5 × 10-13 |

| Extremly-high vacuum | XHV | <10-12 | <10-12 | <7.5 × 10-13 |

Tab. 2: Definition of vacuum classes

How to Overcome Challenges of Vacuum Applications

Because outgassing is a challenge for creating and maintaining clean high-vacuum environments, the right choice of materials and treatments is compulsory in the design and production of vacuum systems. To manufacture products for high (HV) or ultrahigh (UHV) vacuum the following has to be considered: material selection, design, manufacturing and commissioning processes.

The material may not outgas and must be resistant to heat in order to overcome the bakeout temperatures necessary for higher vacuum classes. However, the required precision and high position resolution as well as flatness must be maintained.

For example, common electrical and electronic equipment contains components that either do not suit vacuum applications or only to limited extent. These comprise cables, motors, scaling systems, connectors or limit switches. PI implements specific product features for all these components to strongly reduce outgassing from these components and creating a clean vacuum environment.

Therefore, the materials used for vacuum positioning systems are aluminum alloys, stainless steels, titanium, or bronze. Surface treatment is adapted to the vacuum class, for example, the surfaces of the higher vacuum classes are not coated but blanc aluminum or electro polish. For use in HV and UHV, special vacuum lubricants are used. On request, the lubricant may be defined when placing the order. Vacuum cable insulation is made of PTFE or FEP (Teflon), and also of polyimide (Kapton) or PEEK. The use of adhesives is reduced as far as possible.

Substituting standard materials with vacuum-suitable materials, is a strict requirement of vacuum stage design. Another requirement is the reduction and minimization of the surface of the system.

In addition, it is important to avoid air inclusions since these act like virtual leaks in a vacuum.

The gas in this trapped volume cannot be pumped out easily due to only narrow paths connecting to the vacuum chamber. This delays reaching the required vacuum level.

Trapped volumes are usually caused by unvented or poorly vented blind tapped holes. These are either at the tip of a screw or under the rim of the screw head. Furthermore, holes that are covered either when mounting the positioner on a base plate or fixing a sample on the positioner, often cause virtual leaks. When virtual leaks are caused by screws, the use of vented screws, for example, is recommended.

The conditions and handling regulations for vacuum positioning systems are just as important as the design principles. Vacuum stages are mounted under cleanroom conditions. All components are cleaned in an ultrasonic bath. They are shipped in a packaging free from particles. Before a vacuum positioner is assembled, all pure metal parts undergo a cleaning process in an ultrasonic bath. Electrical and electronic units are wipe-cleaned. Standard, lubricated components such as bearings and guides are degreased, cleaned, and lubricated with special vacuum grease. Ultrasonic-cleaned components are dried in a climate chamber.

The assembly of a stage is carried out in a >> cleanroom or in a flow box. After assembling, the stage must pass a performance test in a clean environment. Vacuum tests are performed for each type of stage and when vacuum-critical changes are made to the product. After assembling, the system is packed in vacuum-sealed bags protected against dirt, air, and humidity: First, the stage undergoes a baking process in a climate chamber. After packing and sealing in an inner vacuum bag, the stage is then put into a second, outer vacuum bag that is then vacuum sealed completely.

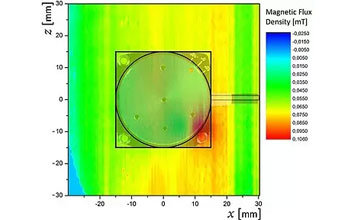

Vacuum-suitable products undergo standard testing at PI. Additionally, customized tests can be ordered for individual vacuum applications. PI has several vacuum chambers with different volumes for bakeout and residual gas analysis.

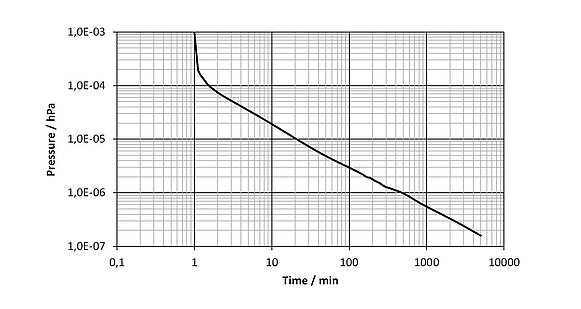

For testing single components or for testing small stages, a chamber is available with a volume of approximately 10 l. The small vacuum chamber is equipped with a pump stand consisting of a 400 l/s (N2) turbomolecular pump and a pressure sensor for continuous pressure sensing, which means that pressures below 10-10 hPa can be reached. A heating facility allows bakeout temperatures up to 200 °C.

A large chamber with a volume of 260 l is designed for large stages up to a length of 800 mm, hexapods, and for multi-axis systems. A pump stand with a 700 l/s (N2) turbomolecular pump and a pressure sensor allow testing down to 10-9 hPa. Bakeout temperatures up to 150 °C are possible with the integrated heating system.

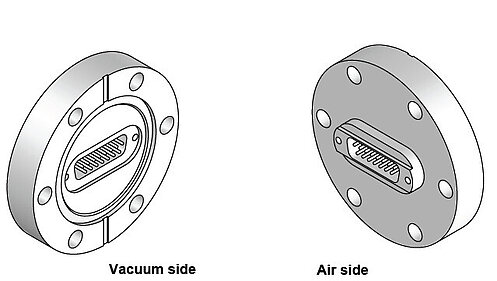

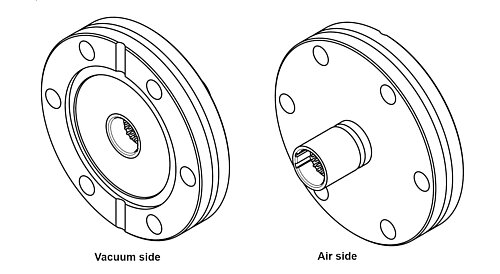

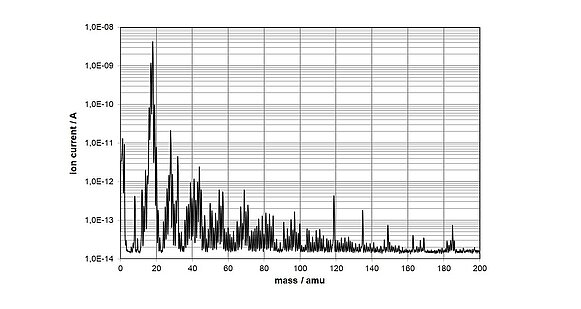

For in-vacuum operation tests on stages flanges of different sizes are available for motor current, linear encoder, limit switches, temperature sensors etc. with various feedthroughs. If interferometric measurements are required or a visual observation of processes is necessary, both chambers can be equipped with inspection windows. A quadrupole mass spectrometer is available for real-time RGA (residual gas analysis) between 1 amu to 200 amu, which can be attached to both chambers.

PI classifies and verifies the vacuum products by vacuum pressure measurements and RGA (residual gas analysis) in the vacuum chambers. Depending on which vacuum level needs to be reached, the chambers and stages are baked out accordingly.