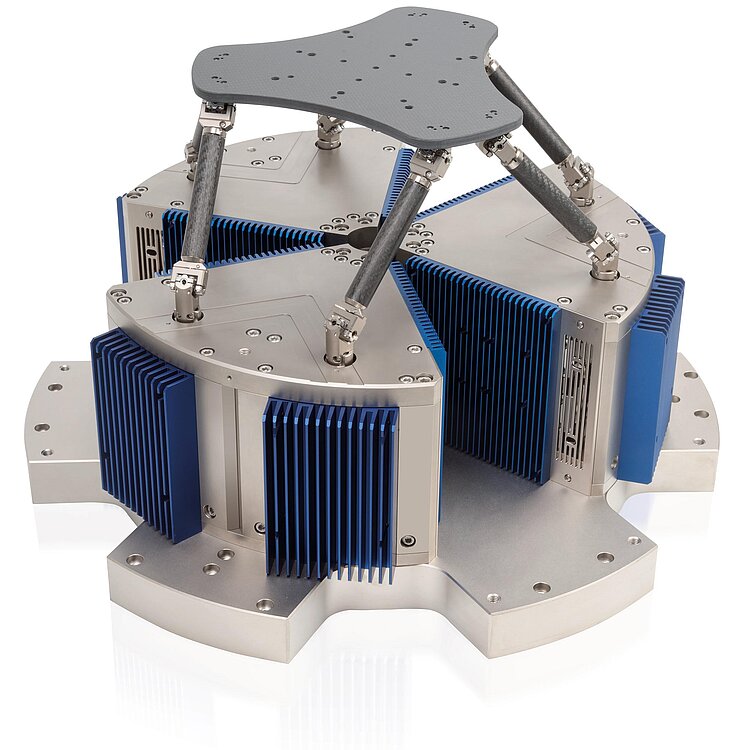

High-dynamics motion hexapod; voice coil drive; 1 kg payload; 250 mm/s maximum velocity; flexures; high-performance power adapter; 3 m cable set

H-860 Motion Hexapod

Magnetic Direct Drive for High Velocity

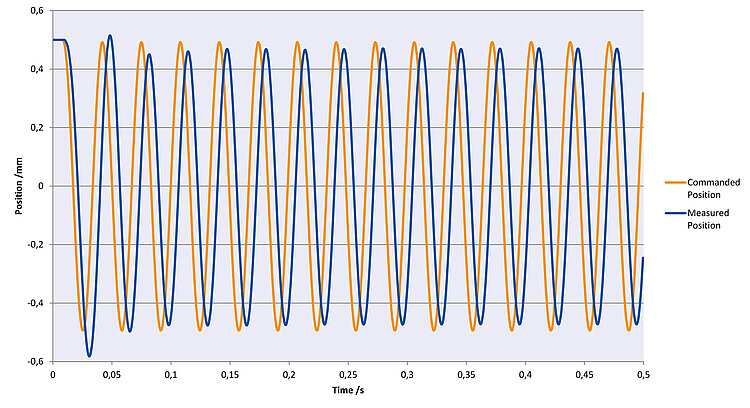

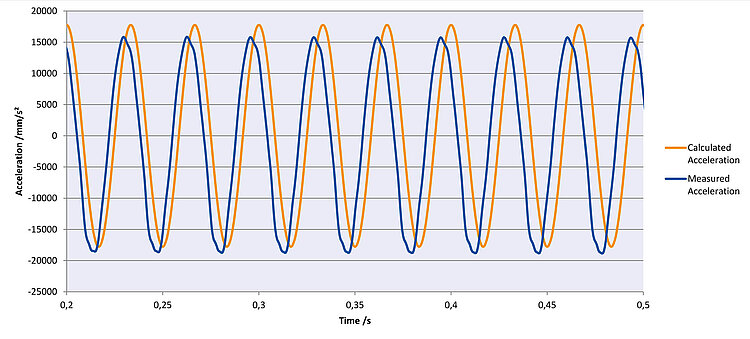

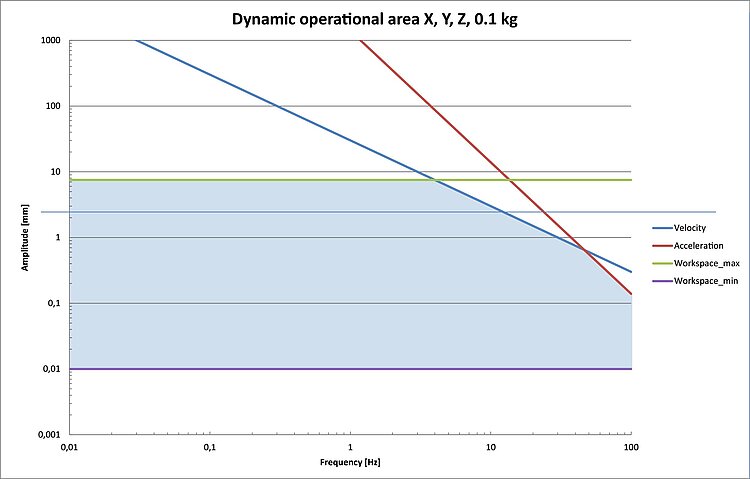

- Velocity to 250 mm/s

- Tracking accuracy with high dynamics

- Friction-free voice coil drive

- Travel ranges ±7.5 mm / ±4°

- Load capacity 1 kg

Thanks to its excellent dynamic properties, the H-860 is ideally suited for motion simulation. The hexapod is used in test systems, e.g., for image stabilization in cameras and mobile devices. Further fields of application include quality assurance of camera test systems and image stabilization software, vibration simulation, eye tracking, simulation of human and artificial motion.

The friction-free drive design is based on voice coil drives and flexure guides. The struts and platform are made of carbon fiber for minimal moved mass and inertia.

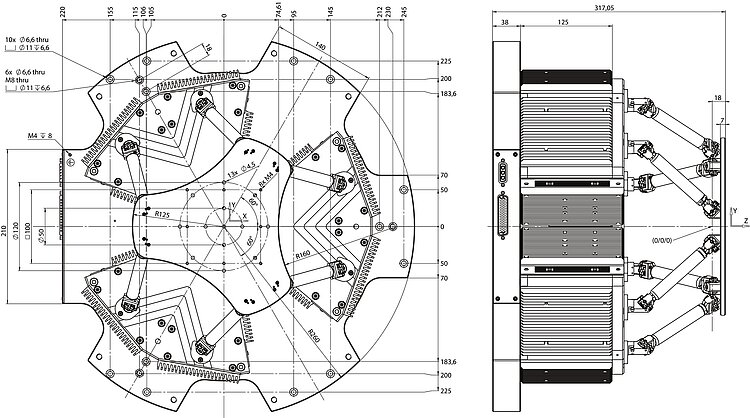

Parallel-kinematic 6-axis system

Parallel-kinematic design for 6 degrees of freedom, making it significantly more compact and stiffer than serial-kinematic systems, no moved cables. Precise running of predefined motion profiles with high path accuracy: sine curves and freely definable trajectories.

PIMag® voice coil drive

Voice coil drives consist of two essential components: a permanent magnet and a coil that is located in the air gap of the magnetic field. Thanks to their low weight and friction-free drive principle, voice coil drives are particularly suitable for applications that require high dynamics and high velocities at limited travel ranges. High scan frequencies and precision positioning are also possible with these drives, because they are free of the effects of hysteresis.

PIVirtualMove

The simulation software simulates the limits of the workspace and payload of a hexapod. Therefore, even before purchasing, you can check whether a particular hexapod model can handle the loads, forces, and torques occurring in an application. For this purpose, the simulation tool takes the position and motion of the hexapod as well as the pivot point and several reference coordinate systems into account.

Specifications

Specifications

| Motion | H-860.S2H | Tolerance |

|---|---|---|

| Active axes | X ǀ Y ǀ Z ǀ θX ǀ θY ǀ θZ | |

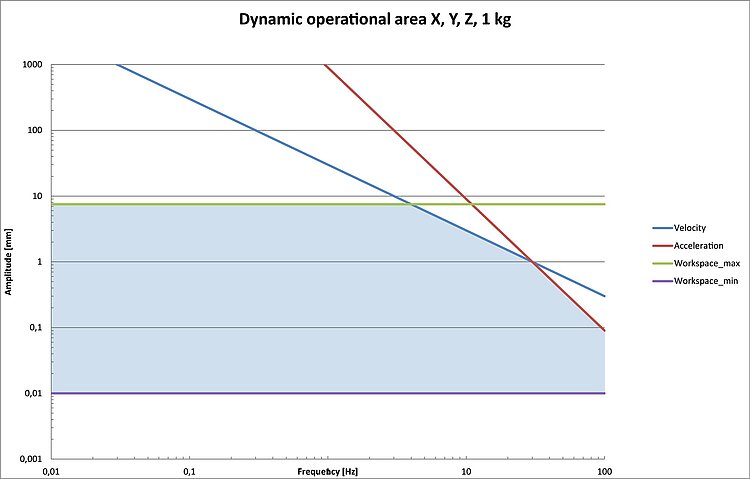

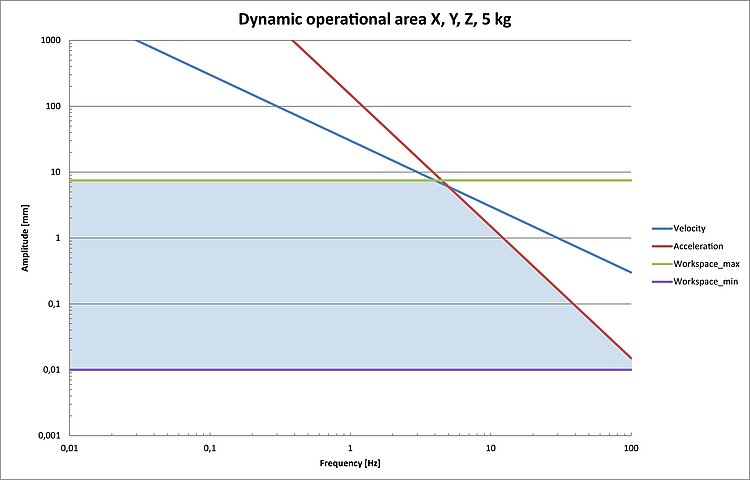

| Travel range in X | ± 7.5 mm | |

| Travel range in Y | ± 7.5 mm | |

| Travel range in Z | ± 7.5 mm | |

| Rotation range in θX | ± 4 ° | |

| Rotation range in θY | ± 4 ° | |

| Rotation range in θZ | ± 4 ° | |

| Maximum velocity in X | 250 mm/s | |

| Recommended velocity in X | 20 mm/s | |

| Maximum velocity in Y | 250 mm/s | |

| Recommended velocity in Y | 20 mm/s | |

| Maximum velocity in Z | 250 mm/s | |

| Recommended velocity in Z | 20 mm/s | |

| Maximum angular velocity in θX | 125 mrad/s | |

| Recommended angular velocity in θX | 10 mrad/s | |

| Maximum angular velocity in θY | 125 mrad/s | |

| Recommended angular velocity in θY | 10 mrad/s | |

| Maximum angular velocity in θZ | 125 mrad/s | |

| Recommended angular velocity in θZ | 10 mrad/s | |

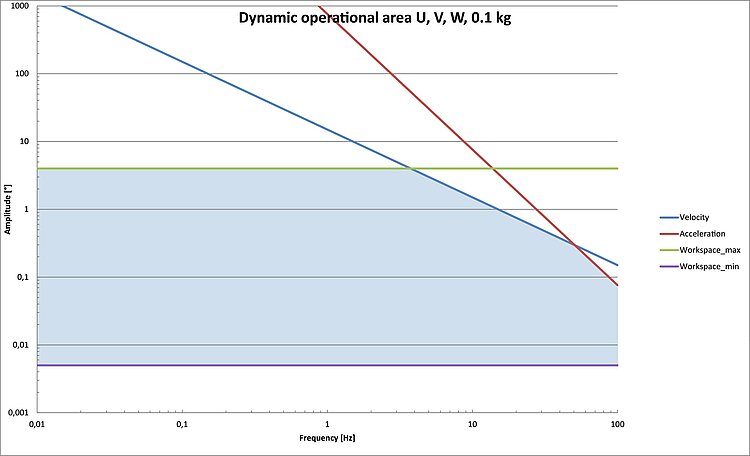

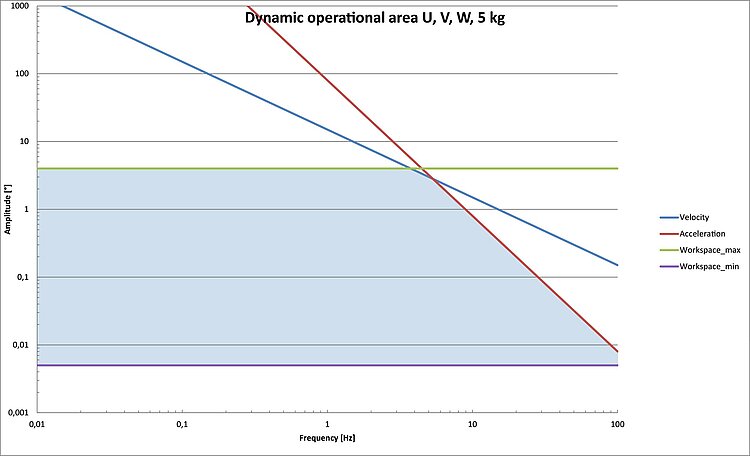

| Amplitude-frequency product in X | 30 mm·Hz | |

| Amplitude-frequency product in Y | 30 mm·Hz | |

| Amplitude-frequency product in Z | 30 mm·Hz | |

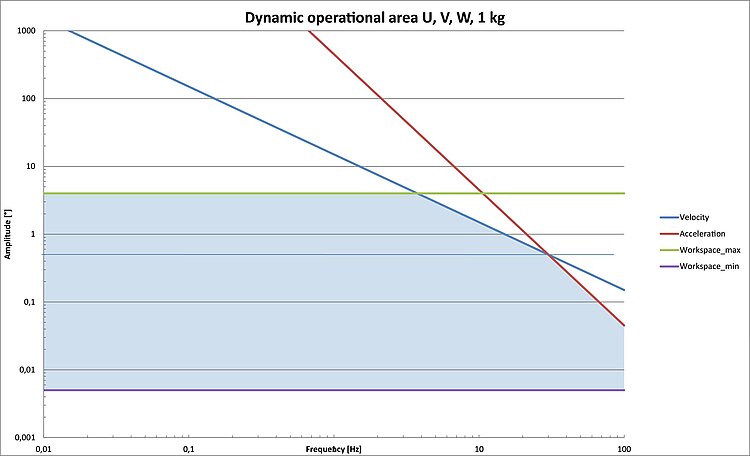

| Amplitude-frequency product in θX | 15 °·Hz | |

| Amplitude-frequency product in θY | 15 °·Hz | |

| Amplitude-frequency product in θZ | 15 °·Hz | |

| Amplitude error | 10 % | max. |

| Phase error | 60 ° | max. |

| Maximum frequency | 30 Hz | |

| Positioning | H-860.S2H | Tolerance |

| Minimum incremental motion in X | 1 µm | typ. |

| Minimum incremental motion in Y | 1 µm | typ. |

| Minimum incremental motion in Z | 1 µm | typ. |

| Minimum incremental motion in θX | 9 µrad | typ. |

| Minimum incremental motion in θY | 9 µrad | typ. |

| Minimum incremental motion in θZ | 9 µrad | typ. |

| Unidirectional repeatability in X | ± 0.5 µm | typ. |

| Unidirectional repeatability in Y | ± 0.5 µm | typ. |

| Unidirectional repeatability in Z | ± 0.5 µm | typ. |

| Unidirectional repeatability in θX | ± 9 µrad | typ. |

| Unidirectional repeatability in θY | ± 9 µrad | typ. |

| Unidirectional repeatability in θZ | ± 9 µrad | typ. |

| Backlash in X | 0.2 µm | typ. |

| Backlash in Y | 0.2 µm | typ. |

| Backlash in Z | 0.06 µm | typ. |

| Backlash in θX | 4 µrad | typ. |

| Backlash in θY | 4 µrad | typ. |

| Backlash in θZ | 4 µrad | typ. |

| Integrated sensor | Absolute linear encoder | |

| Drive Properties | H-860.S2H | Tolerance |

| Drive type | Voice coil | |

| Maximum power consumption | 300 W | |

| Mechanical Properties | H-860.S2H | Tolerance |

| Stiffness in X | 0.7 N/µm | |

| Stiffness in Y | 0.7 N/µm | |

| Stiffness in Z | 8 N/µm | |

| Maximum load capacity, base plate in any orientation | 1 kg | |

| Maximum load capacity, base plate horizontal | 1 kg | |

| Overall mass | 30 kg | |

| Material | Stainless steel, aluminum | |

| Miscellaneous | H-860.S2H | Tolerance |

| Operating temperature range | 0 to 50 °C | |

| Connector | HD D-sub 78 (m) | |

| Recommended controllers/drivers | C-887.5x |

Ask about customized versions.

When measuring position specifications, typical velocity is used. The data is included in the delivery of the product in the form of a measurement report and is stored at PI.

The maximum travel ranges of the individual coordinates (X, Y, Z, θX, θY, θZ) are interdependent. The data for each axis shows its maximum travel range when all other axes are in the zero position of the nominal travel range and the default coordinate system is in use, or rather when the pivot point is set to 0,0,0.

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Product Note

Product Change Notification Motor Driven Products

Datasheet

Documentation

User Manual H860T0002

H-860 Hexapod with Magnetic Direct Drive for High Velocity

3D Models

3-D model H-860.S2H

Software Files

PIVirtualMove

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

How to Get a Quote

Questions? - Ask a PI Engineer

Technology

Hexapods as Motion Simulator

Motion simulators have higher motion dynamics requirements (shakers).

Hexapods and SpaceFAB

Hexapods are systems for moving and positioning loads in six degrees of freedom, in three translational and three rotational axes.

Magnetic Direct Drives

In particular in terms of wear and dynamics, magnetic direct drives offer advantages compared to common spindle-based technologies.