Operating Linear Stages under Force Control

How Advanced Control Algorithms enable Precision Force Control, Connecting the Future to the Past – from Artificial Feel” to Haptics of Augmented Reality

Each day all around the world, both kids and adults step into alternate augmented and virtual realities, reprising roles in surreal landscapes. Whether it be a gold chain wearing magenta gorilla in sunglasses or a popular protagonist literary heroine surrounded by anthropomorphic playing cards, a world of visual immersion awaits the initiated. Visual immersion is omnipresent, but how though do we interact haptically with virtual and augmented worlds?

The Golden Age of Aviation and “Artificial Feel”

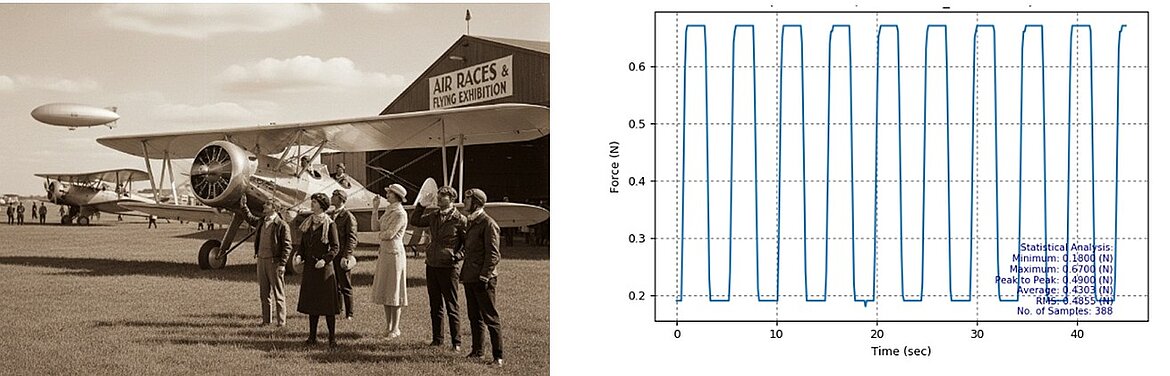

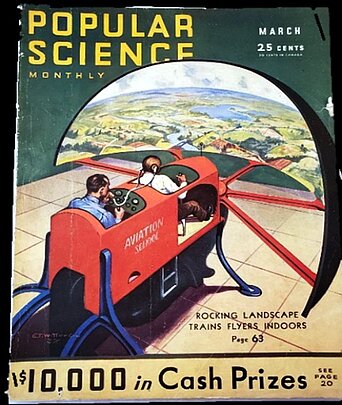

One of the first examples of “artificial feel” can be found in early flight training simulators, featured in publications like Popular Science during the golden age of aviation. These pneumatically driven, projector-based simulators were intended to provide tactical feedback to train muscle memory in preparation for real flight. This antecedent to our modern visions of virtual world interaction draws attention to a strange truth; we’re still evolving our idea and engineering of “artificial feel” to map real interactions into imaginary landscapes….and precision motion is playing an increasingly important part.

Left: Designers of pneumatics-based force feedback used in early flight simulators could hardly have imagined modern VR simulators and battery-operated hand-held controllers with integrated electric force-feedback (right).

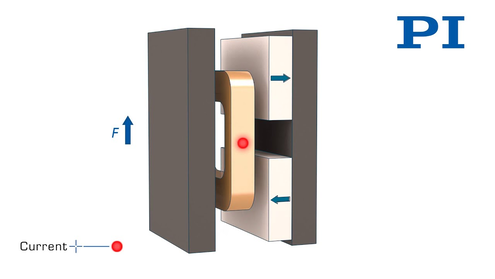

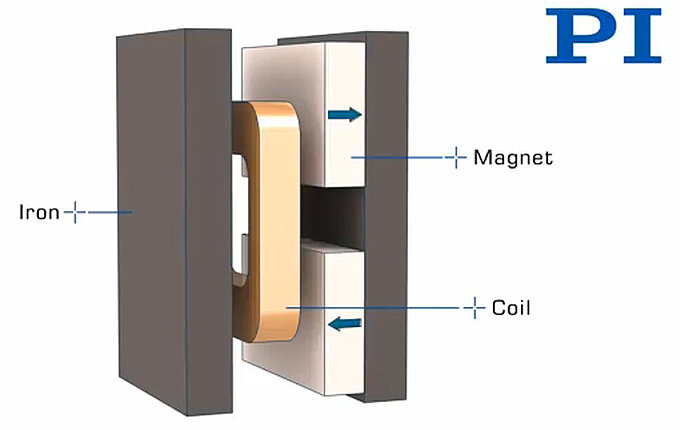

The Lorentz Force Law and Linear Motor Applications of Precision Force

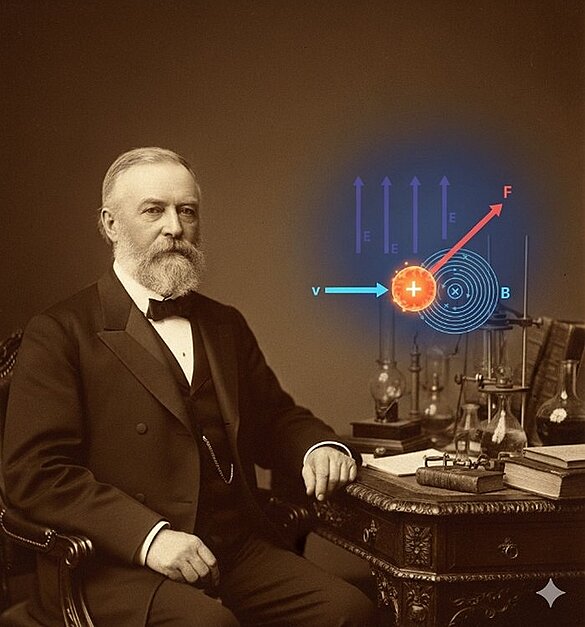

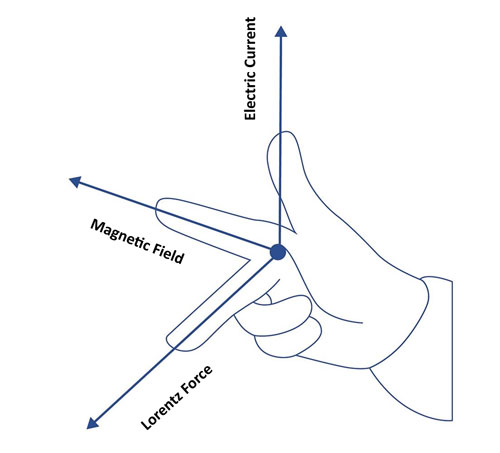

Hendrik Lorentz completed the final derivation of his eponymous force law in 1895, forming a part of the foundation of classical electrodynamics. This law dictates that a current-carrying coil in a static magnetic field (B->) will experience a resulting magnetic force (and/or torque) that changes proportionally with any changes in the applied coil current (I->). This is expressed by the mathematical relationship shown below:

F-> = I(L-> x B->)

Where:

- F is the force vector (Newtons, N)

- I is the scalar current (Amperes, A)

- L is the current length vector (meters, m)

The Lorentz Force Law is critical to the use of linear and voice coil motor stages in the precise and selective application of force for precise touch applications.

As can be seen in this relationship, when rearranged, the motor force is linearly proportional to applied motor current (in static B field):

F=kfI

Where:

- kf is equal to LB

This is a fundamental aspect of the behavior of linear motors and kf is known as the motor force constant, where B it the static B-Field (and L is coil length immersed in the B-Field), which a function of motor design and construction.

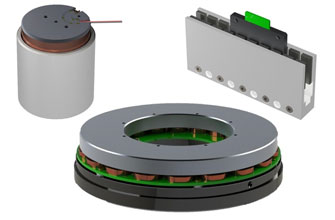

Applying Precise Force with Linear Motor and Voice Coil Stages

Naturally, the precise application force via voice coils or linear motors is influenced by additional characteristics, including guiding systems, amplifier, and algorithmic control.

First and foremost, the amplifier dynamic range and noise characteristics dictate the quantized current resolution and corresponding Minimum Incremental Force (MIF) that can be applied. A noisy amplifier with minimal dynamic range limits the resolution of current, and correspondingly the precise application of force.

Often, a secondary limitation is the quality of type of guiding, whether it be flexure, recirculating ball or crossed-roller bearings or air bearings. Any non-repeatable or otherwise non-uniform friction characteristic in the guiding produces a drag or absorption of applied force otherwise limiting precise touch.

Finally, algorithmic control and feedback is of utmost importance. This addresses the capability to apply force-calibrated, precisely controlled current with real-time deterministic monitoring and computation, as well as the flexibility to map and switch between force and position control, both of which are key

Practical Results using PI Positioners with ACS-based Control Systems

When precise force application with predictable, scalable reliability is required, PI draws on its core catalog of motion and control expertise. Below, we present two distinct solutions, based on different guiding principles, motor types, and control/algorithmic platforms. Both approaches, however, represent optimal solutions for their respective force-touch applications

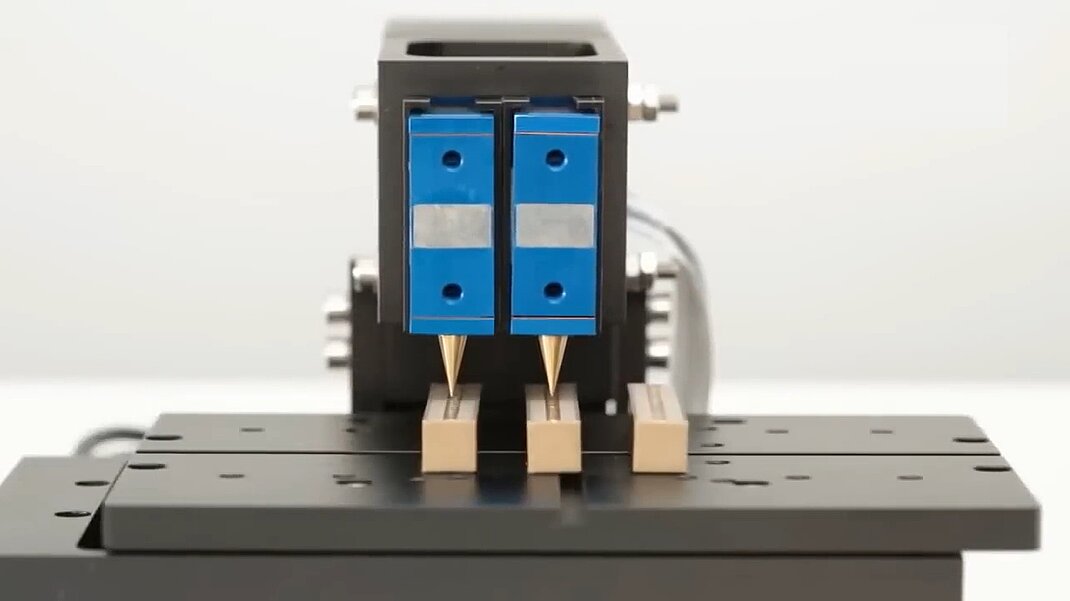

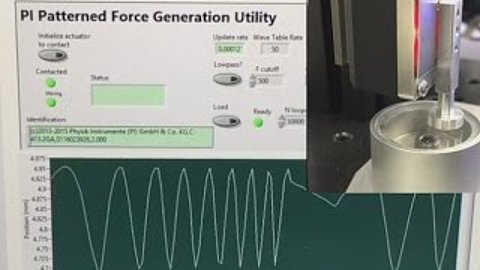

V-308 Precise Force Touch Solution for Production Scale Haptic Tests

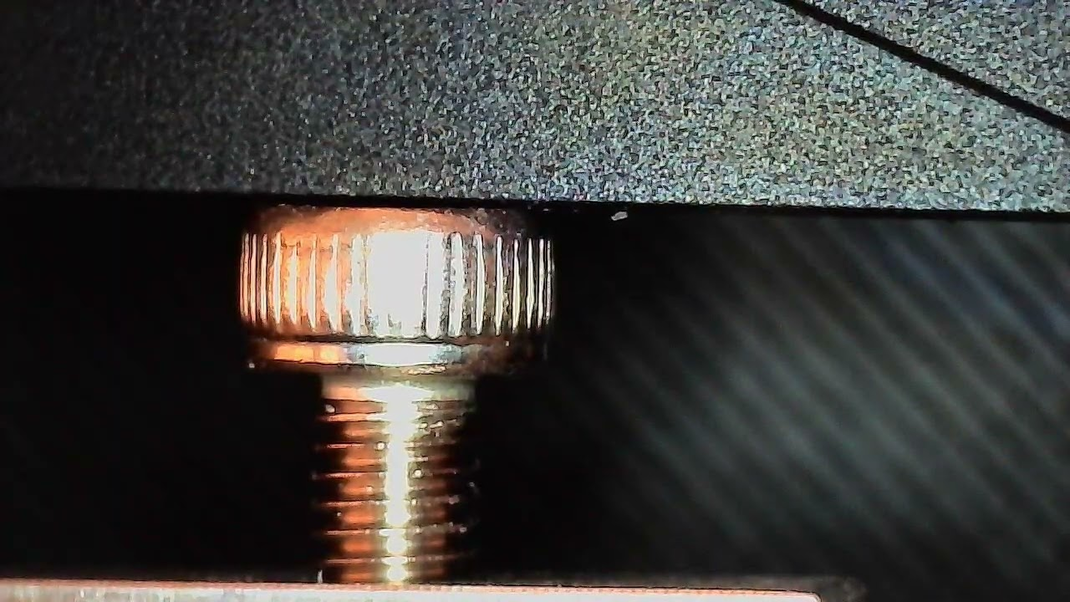

The V-308 is a compact voice-coil nanopositioning stage designed for vertical applications. It features a magnetic counterbalance that can be calibrated to achieve zero net force under touch end-effector test loads, making it ideal for touchdown-type testing and fabrication processes.

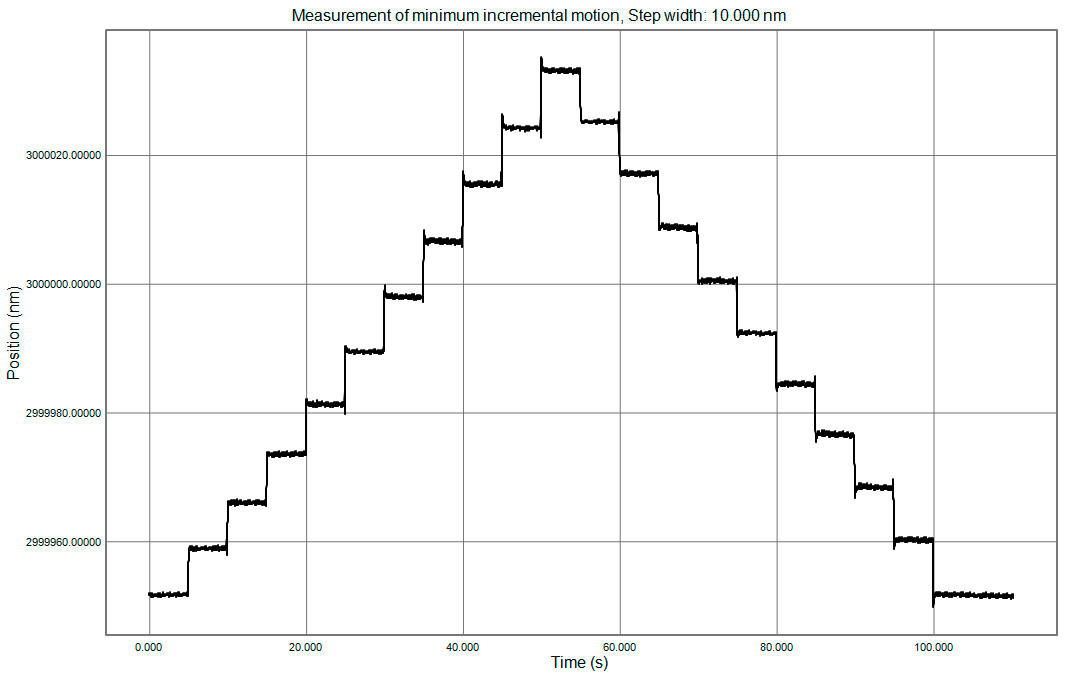

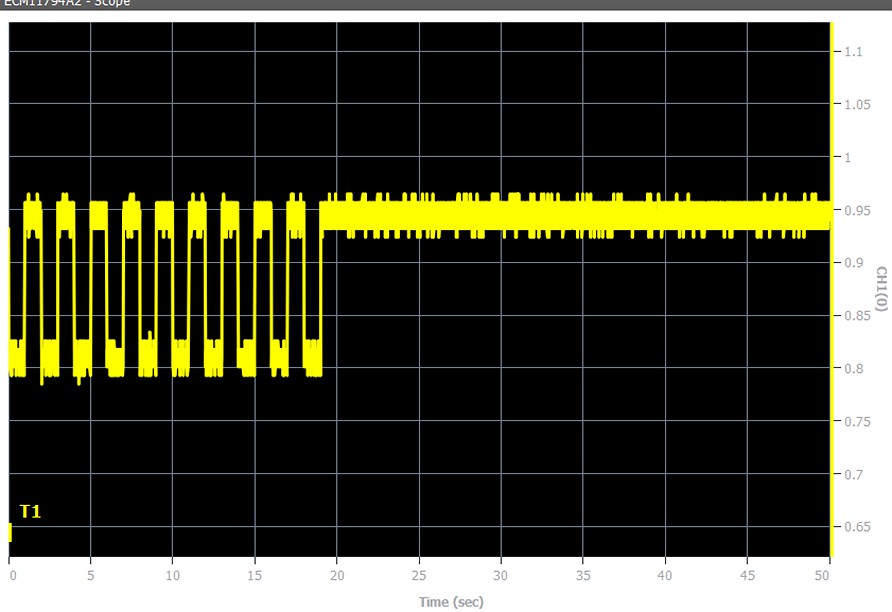

The V-308 stage was originally designed for nano-focusing applications in super-resolution microscopy and surface metrology.Its integrated sensor provides 1nm resolution and the stage can produce repeatable nanometer scale incremental motion (10nm steps shown the test graph). An integrated, user-adjustable magnetic counterbalance allows for weight-force compensation.

This allows all force application to be through motor transduction (and not weight support). This reliable force application is supported by exceptional guidance using crossed-roller bearings with anti-friction guides, ensuring minimal difference between static and rolling transitional cases.

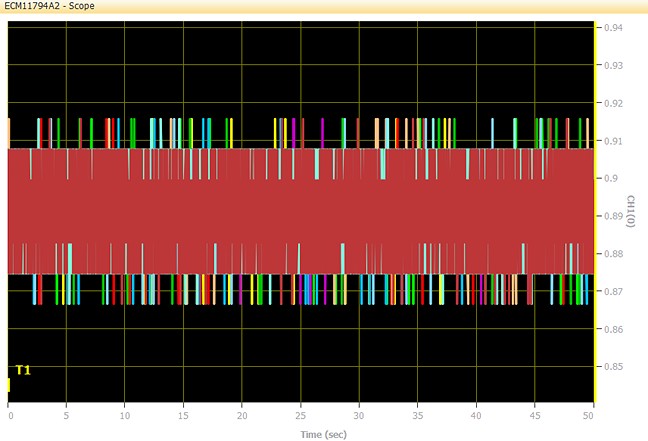

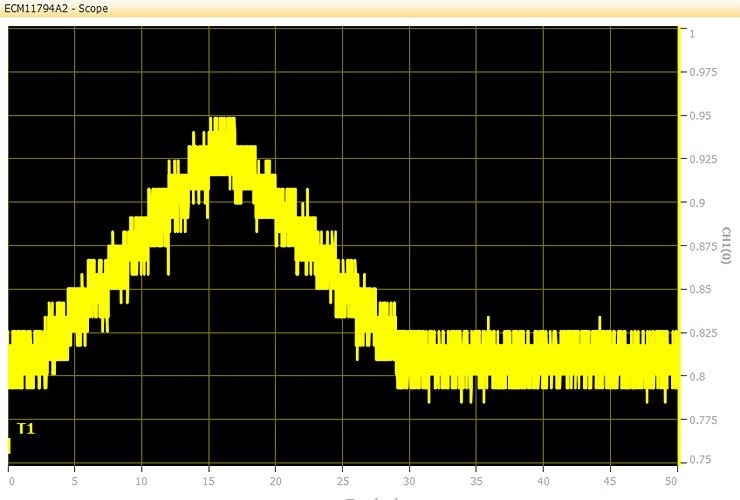

Here we present precise touch test results including Minimum Incremental Force and Force Repeatability Tests:

With precise measurement of motor force constant and onboard computation and force control functions, the V-308 nanopositioning stage is used as both force transducer and measurement device to apply and maintain force at mN (or gram levels). As can be seen below, Minimum Incremental Force was 100mN (10g) with baseline force noise and repeatability at 50mN (5g).

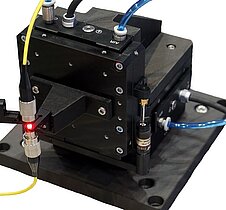

Air Bearing Stages for Production Precision Force Application Processes

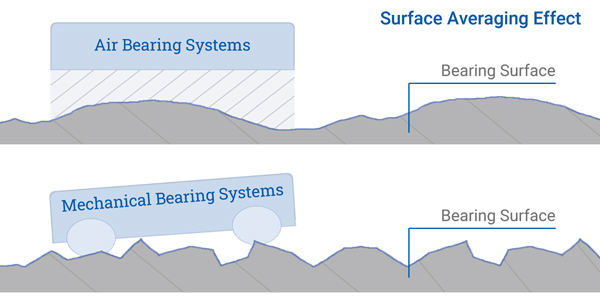

Air bearings can provide the highest-level of performance when suitably paired with low-noise, high dynamic range amplifiers. Air-bearing solutions are free from any mechanical contact or intrinsic non-uniform friction characteristics and are completely non-wearing making them ideal for repetitive testing typical to haptics and other force touch processes.

PI offers a range of vertically counterbalanced force touch solutions based on air bearing technology with production validated performance to single and sub mN ranges.

Air bearings replace mechanical contact and friction with an air film. Another advantage of air bearings is the surface-averaging effect, enabling much better geometric performance (pitch, yaw, roll) compared to traditional bearings with mechanical point or line contact.

The Future of Artificial Feel and Haptics

PI and our industrial and research partners are working toward the next generation of more immersive and accurate haptic solutions with electromagnetic and piezoelectric solutions supporting virtual, augmented and a range of sensorial realities.

Contact a PI applications expert and let’s work together to enable the future!

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy