PIglide voice coil miniature linear stage with air bearings; Voice coil; 10 mm travel range; 30 N load capacity; 200 mm/s maximum velocity; Incremental linear encoder, 20 µm sensor signal period, sin/cos, 1 V peak-peak; 0.5 m cable length

A-142 PIglide Voice Coil Linear Stage with Air Bearings

High Performance • Cleanroom-Compatible • Option for Vertical Mounting

- Velocity to 200 mm/s

- Acceleration to 10 m/s2

- Sensor resolution: 5 nm

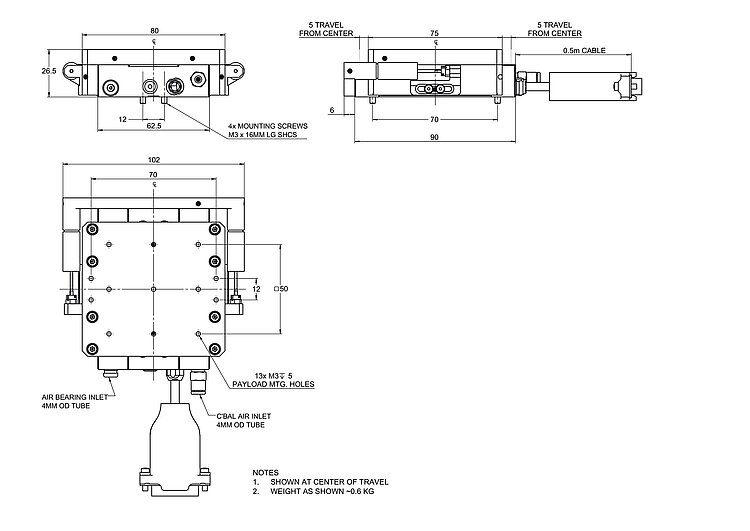

- Low profile of 27 mm

- Very compact motion platform: 75 mm × 80 mm

- Travel range to 10 mm

- Load capacity to 3 kg

Ultra-Compact Motorized Air Bearing Linear Stage

The A-142 miniature linear translation stage is a unique, high performance precision nanopositioning system, featuring a direct-drive voice coil linear motor, a high-resolution linear encoder and frictionless and stiff air bearing guides. It is ideally suited for maintenance-free, high duty cycle industrial scanning and positioning applications. The special design of this voice coil-driven stage does not use any internal moving cables.

Miniaturized Stage Design for High Performance Linear Motion

Despite its small size, this miniature linear translation stage provides high performance linear motion that cannot be met by conventional stages with mechanical bearings. Air bearing slides do not require lubricants and do not generate particles which makes them cleanroom compatible, another advantage in photonics, optics and semiconductor related test, metrology and alignment applications. Since the direct-drive, voice coil linear motor and the air bearings are completely maintenance-free and wear-free, this compact translation stage can be used in industrial, high throughput, 24/7 precision motion applications.

High Precision, Repeatability and Ultra-Smooth Motion

Based on the direct measuring linear encoder, and the lack of friction in the direct drive motor and air bearing linear guides, this miniaturized air bearing slide can provide extremely smooth motion in a very wide dynamic range. It provides, high velocity up to 200 mm/s and high acceleration to 1 g. The integrated linear encoder features 5 nanometers of sensor resolution and the stage platform provides 50 nanometers minimum incremental motion. It can be commanded to any position within its travel range with 0.1 µm position repeatability. The high speed and acceleration of the voice coil linear motor stage are an asset when it comes to high velocity scanning applications.

Vertical Z-Stage Operation – Counterbalance Option

The A-142 miniature translation stage is also available with a counterbalance to enable operation as a vertical positioning stage. The counterbalance keeps the motor current down during steady stage / position hold operations.

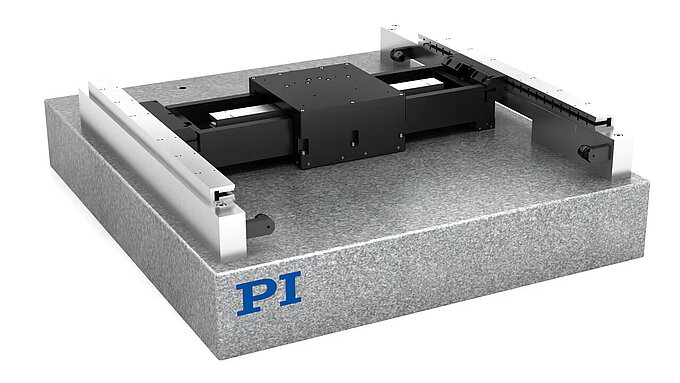

Multi-Axis Miniature Stage Applications – Miniature XY Tables and XYZ Stages

Two A-142 air bearing miniature stages can be assembled to form a miniature XY table and compact 3-axis stage combinations are also available, for example to handle complex high-speed multi-axis alignment tasks on small optical or fiber optical components. Talk to a PI engineer about your application to get free advice for the best system configurations.

Motion Controllers, Programming, Computer Control Options

PI offers a selection of high-performance motion controllers to program and operate these air bearing miniature linear slides. We recommend EtherCat® compatible controllers, such as the A-811 – A-814 series of high-performance ACS-based motion controllers. PI motion controllers come with a host of programming examples, available alignment routines and a simulation tool that allows customers to write programs and run basic system tests before their motion system is shipped.

Why use Air Bearings and Air Bearing Stages?

Linear air bearings (and rotary air bearings as well) provide better geometric performance (pitch, yaw, roll, straightness and flatness, wobble and eccentricity) than conventional mechanical bearings. They replace the rolling or sliding contact from mechanical ball bearings or cross-roller bearings with a friction-free air film for a virtually unlimited service life. Air bearing linear slides and rotary tables are ideally suited for clean room applications, because they do not rely on lubricants and do not generate particles. PI has engineering teams with decades of air bearing design, manufacture and assembly experience and can provide a large spectrum of air bearing motion systems, from standard single-axis miniature stages to complex customized multi-axis granite motion systems.

Why use Voice-Coil Motors in Compact Linear Stages?

Voice coil linear motors provide frictionless linear motion with very rapid response, acceleration and high velocity. For applications where 24/7 high dynamics scanning motion is required, with travel ranges of typically 25 mm (1 inch) or below, a voice coil linear motor is an ideal solution. Its compact design, maintenance-free and particle generation free operation are additional advantages. For longer travel ranges, 3-phase linear motors are recommended, such as found in the A-123 air bearing linear slides or V-417 linear stages with mechanical bearings.

Accessories and Options

- PIglide filter and air preparation kits

- Pneumatic counterbalance for vertical stage mounting

Applications for Miniature Air Bearing Stages

The A-142 air bearing miniature linear stage is ideally suited for high-precision motion applications, such as metrology, photonics alignment systems, optics positioning, and scanning. The noncontact design is ideal for cleanroom applications.

Specifications

Specifications

| Motion | A-142.010A1 | A-142.010A2 | Tolerance |

|---|---|---|---|

| Active axes | X | X | |

| Travel range in X | 10 mm | 10 mm | |

| Acceleration in X, unloaded | 10 m/s² | 10 m/s² | max. |

| Maximum velocity in X, unloaded | 200 mm/s | 200 mm/s | |

| Straightness error in Y (straightness) | ± 0.1 µm | ± 0.1 µm | typ. |

| Straightness error in Z (flatness) | ± 0.5 µm | ± 0.5 µm | typ. |

| Positioning | A-142.010A1 | A-142.010A2 | Tolerance |

| Minimum incremental motion in X | 0.05 µm | 0.05 µm | typ. |

| Positioning accuracy in X, calibrated | ± 0.2 µm | ± 0.2 µm | typ. |

| Bidirectional repeatability in X | 0.1 µm | 0.1 µm | max. |

| Reference switch | Encoder index | Encoder index | |

| Limit switches | Hall effect | Hall effect | |

| Integrated sensor | Incremental linear encoder | Incremental linear encoder | |

| Sensor signal | Sin/cos, 1 V peak-peak | Sin/cos, 1 V peak-peak | |

| Sensor signal period | 20 µm | 20 µm | |

| Sensor resolution | 5 nm | 5 nm | |

| Drive Properties | A-142.010A1 | A-142.010A2 | Tolerance |

| Drive type | Voice coil | Voice coil | |

| Nominal voltage | 48 V | 48 V | |

| Peak voltage | 80 V | 80 V | |

| Nominal current, RMS | 0.5 A | 0.5 A | typ. |

| Peak current, RMS | 2 A | 2 A | typ. |

| Drive force in positive direction of motion in X | 5 N | 5 N | typ. |

| Drive force in negative direction of motion in X | 5 N | 5 N | typ. |

| Peak force in positive direction of motion in X | 20 N | 20 N | |

| Peak force in negative direction of motion in X | 20 N | 20 N | |

| Force constant | 10 N/A | 10 N/A | |

| Resistance phase-phase | 7 Ω | 7 Ω | typ. |

| Inductance phase-phase | 7.8 mH | 7.8 mH | |

| Back EMF | 9.7 V·s/m | 9.7 V·s/m | max. |

| Mechanical Properties | A-142.010A1 | A-142.010A2 | Tolerance |

| Permissible push force in X | 10 N | 10 N | max. |

| Permissible push force in Z | 30 N | 30 N | max. |

| Permissible torque in θX | 0.5 N·m | 0.5 N·m | max. |

| Permissible torque in θY | 0.5 N·m | 0.5 N·m | max. |

| Moved mass in X, unloaded | 250 g | 250 g | |

| Guide | Air bearing with air preload | Air bearing with air preload | |

| Overall mass | 600 g | 600 g | |

| Material | Hardcoat aluminum, stainless steel mounting hardware | Hardcoat aluminum, stainless steel mounting hardware | |

| Miscellaneous | A-142.010A1 | A-142.010A2 | Tolerance |

| Operating temperature range | +15 to +25 °C | +15 to +25 °C | |

| Connector | D-sub 3W3 (m) | D-sub 3W3 (m) | |

| Sensor connector | D-sub 15 (m) | D-sub 15 (m) | |

| Air connector | One-touch fitting for tubing with 4 mm outer diameter | One-touch fitting for tubing with 4 mm outer diameter | |

| Operating pressure | 445 to 515 (865 to 75 psi) kPa | 445 to 515 (65 to 75 psi) kPa | |

| Air consumption | 28 L/min | 28 L/min | max. |

| Air quality | Clean (filtered up to 1.0 µm or better) - ISO 8573–1 class 1 ǀ Oil free - ISO 8573–1 class 1 ǀ Dry (-15 °C dew point) - ISO 8573–1 class 3 | Clean (filtered up to 1.0 µm or better) - ISO 8573–1 class 1 ǀ Oil free - ISO 8573–1 class 1 ǀ Dry (-15 °C dew point) - ISO 8573–1 class 3 | |

| Cable length | 0.5 m | 0.5 m | |

| Recommended controllers/drivers | A-81x ACS-based motion controller for medium power requirements, 2 / 4 / 6 axes A-82x ACS-based motion controller for high power requirements, 4 / 6 / 8 axes | A-81x ACS-based motion controller for medium power requirements, 2 / 4 / 6 axes A-82x ACS-based motion controller for high power requirements, 4 / 6 / 8 axes |

Note on acceleration and velocity: The given values are valid in an unloaded state.

Note on straightness error: Dependent on the flatness of the surface, on which the stage is mounted.

Note on minimum incremental motion: Is directly related to the system stability (servo jitter); this depends on the servo drive used.

Note on positioning accuracy: The calibrated accuracy can only be achieved with a controller-driven error compensation. The stage must be ordered with a controller from PI to reach these values. Accuracy values assume short duration and do not consider the long-term effects of thermal drift on the stage.

Note on the permissible push force and moment: Assumes an operating pressure of the air bearings of 480 kPa.

Note on the sensor resolution: Assumes a 4096x interpolation. Contact PI for the use of other factors.

Note on the operating pressure: To protect the stage against damage, it is recommended to connect an air pressure sensor to the E-Stop input of the controller.

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Datasheet

Documentation

User Manual A142D001

A-142 Series Miniature Linear Air Bearing Stage with Voice Coil Drive

3D Models

3D model A-142

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

PIglide voice coil miniature linear stage with air bearings; voice coil; 10 mm travel range; 30 N load capacity; 200 mm/s maximum velocity; incremental linear encoder, 20 µm sensor signal period, sin/cos, 1 V peak-peak; 0.5 m cable length; pneumatic counterweight for vertical mounting