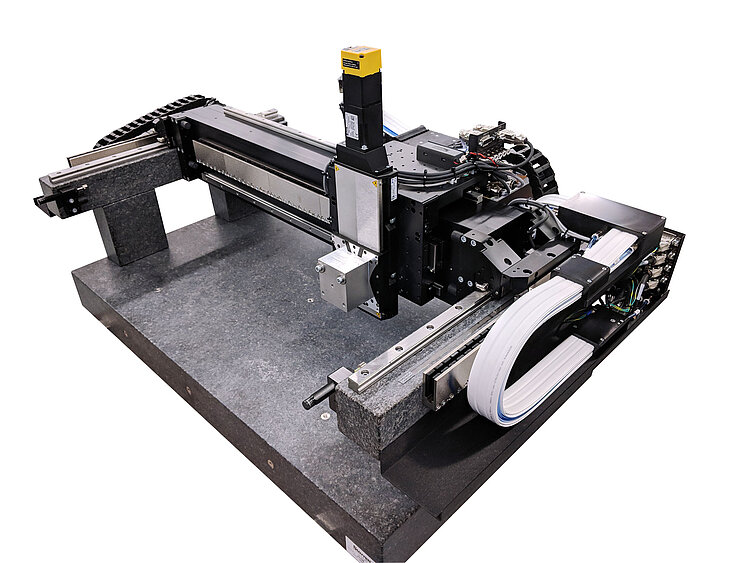

A-351 MGS Gantry System with Linear Motors

Robust Compact Design with Recirculating Ball Bearing Guides for High Load Capacity.

- Overhead moving XY gantry

- Precision recirculating ball bearing guides

- Absolute encoder

- High-performance ironless linear motors

- Various travel ranges. Options and customized adaptations

- Flexible modular platform

Overview

The MGS gantry system has been designed to maximize throughput for applications requiring overhead motion. This stage is ideal for 3D printing, assembly, pick-and-place, alignment, inspection, and industrial automation applications.

The MGS uses preloaded linear mechanical bearings which are designed to provide optimized stiffness and precision. Optional stainless steel guide rails can be delivered.

The gantry axis incorporates dual linear motors and dual linear encoders. Ironless linear motors provide smooth motion and no cogging or attractive forces. The linear motor and linear encoders are noncontact devices, so there is no backlash, wear, or maintenance concerns.

The A-351 is coupled with industry-leading controllers and drive modules from ACS that offer superior servo performance, advanced control algorithms to improve dynamic performance and error compensation, and a wide suite of software development tools.

Options and customized adaptations

- Base made of granite or aluminum

- Adjustable work height

- Systems for reducing vibration

- Additional drag chains

- Performance of the linear motors

- Liquid cooling of the linear motors

Application fields

Scanning, Digital printing, Electronics assembly and inspection, AOI (Automatic Optical Inspection), Automation.

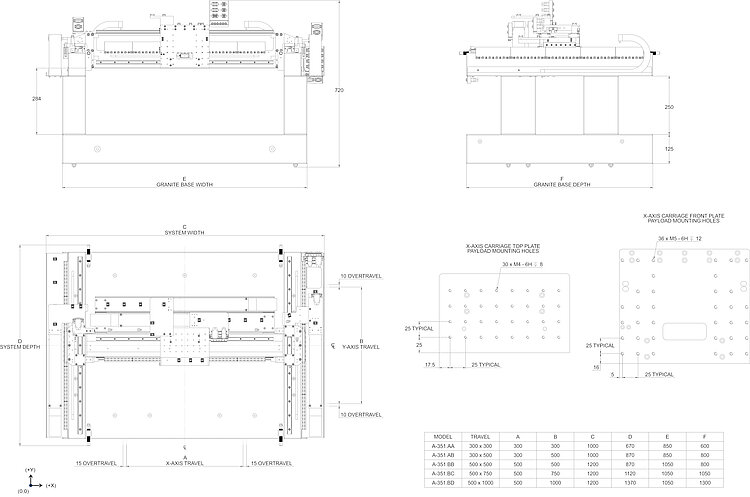

Specifications

Specifications

Motion | Unit | Bridge axis | Gantry axis |

|---|---|---|---|

Travel range | mm | 300 500 | 300 500 750 1000 |

Guide | Recirculating ball bearing guide | ||

Drive | 1 × Ironless 3-phase linear motor | 2 × Ironless 3-phase linear motor | |

Measuring system | Absolute linear encoder, 1 nm sensor resolution, BiSS-C, steel measuring scale | 2 × Absolute linear encoder, 1 nm sensor resolution, BiSS-C, steel measuring scale | |

Load capacity | 20 kg | ||

Positioning accuracy, calibrated (1) | µm | ±1 | |

Bidirectional repeatability | µm | ±0.5 | |

XY orthogonality | µrad | 25 | |

Max. velocity, unloaded (2) | m/s | 2 | 1 |

Moved mass | kg | 4.5 | Depending on the travel range of the bridge axis: 300 mm: 25 kg 500 mm: 30 kg |

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.