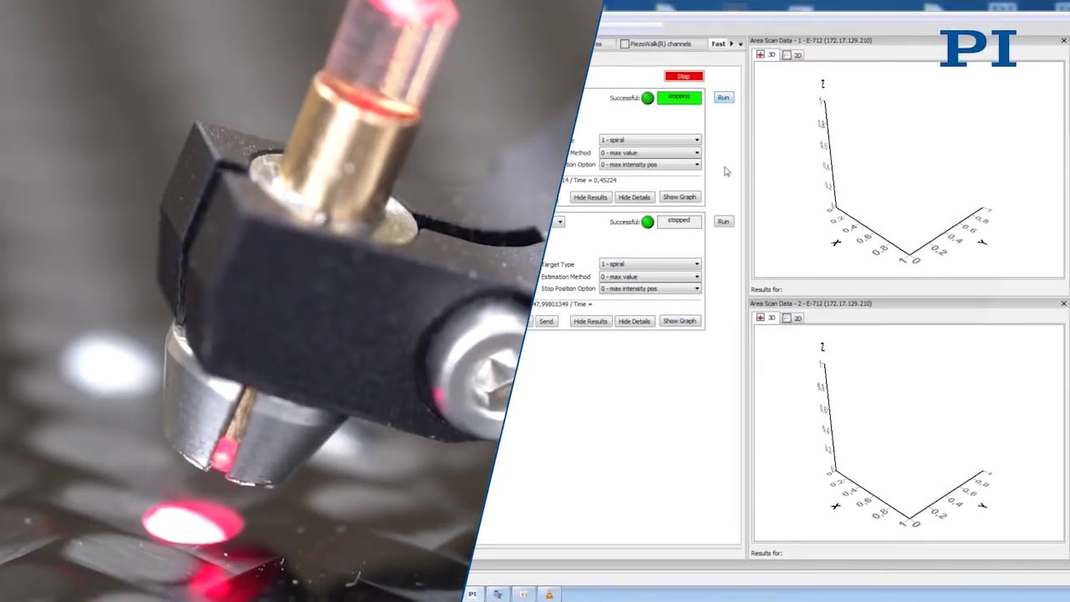

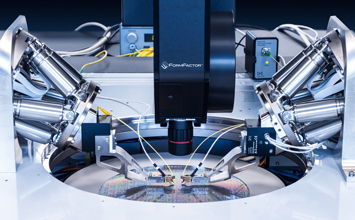

Photonics automation is a prerequisite of scalable photonics components production. Automated, active optical alignment systems increase throughput in production of optics components and SIP photonics component packaging and testing, significantly. Running multiple tasks and algorithms fast and in parallel is key to big time savings. Automated optical assembly and alignment systems can now bring down the manufacturing cycles for SiPh fiber optical photonics components to a few minutes. Unlike the moderate precision required to probe electrical wafers, automated probing of an optical wafer is much harder because the minute dimensions of the optical waveguides on silicon photonics wafers (~150 to 200 nanometers). Everything is even much more delicate than what’s known with single-mode, optical glass fibers, where average core diameters are in the range of 9 microns. Nanopositioning equipment is therefore essential to provide the accuracy and resolution required to automate alignment precisely over such minute distances.

Ingredients for Photonics Automation: Software, Image Processing, Gantry Robots, Nanometer Precision

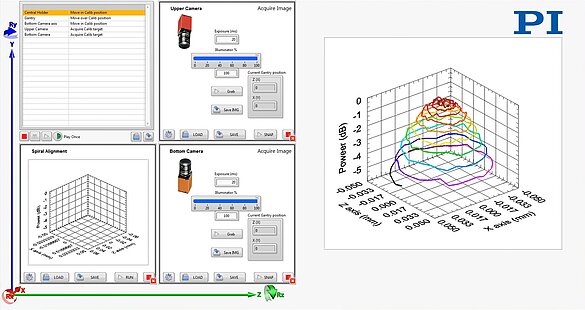

Nanopositioning mechanics alone are not enough to master the challenge of industrial scale photonics packaging automation. New algorithms and advanced software need to work seamlessly together for success.

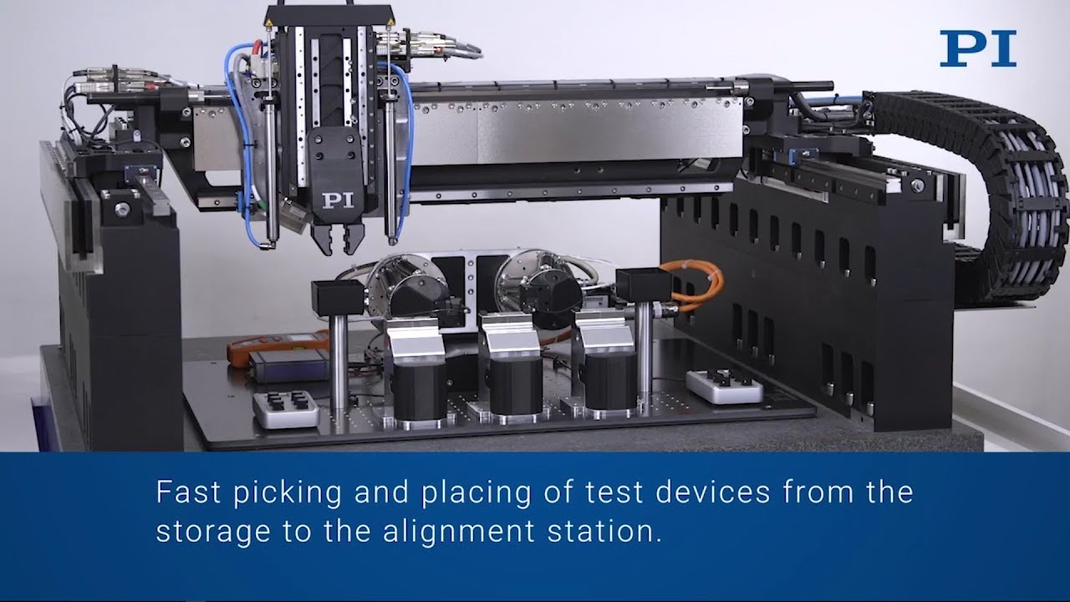

Adding vision guided robots for pick-and-place further improves throughput in automation. Combinations of XYZ gantry robots and hexapod 6-axis robots with grippers have been suggested to enhance the scope.

Downloads

Alignment for Optics and Silicon Photonics

Fast Multi-Channel Photonic System

Silicon Photonics Set the Pace on the Data Highway

Automated Packaging As Complete Solution

Digital Brochure: Fast, Industrial, All-Digital Optical Alignment Subsystems

Unique capabilities address technical and economic requirements for test and packaging of silicon photonics and fiber optic devices