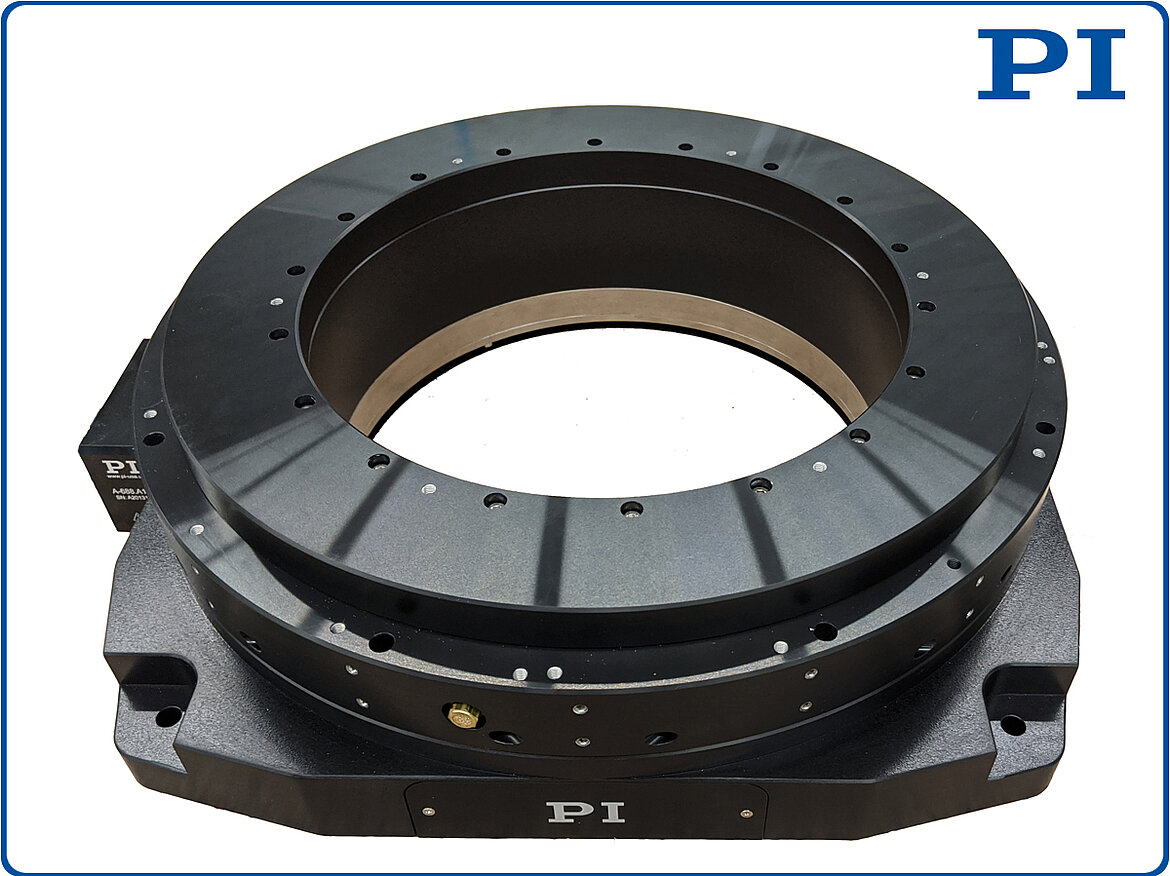

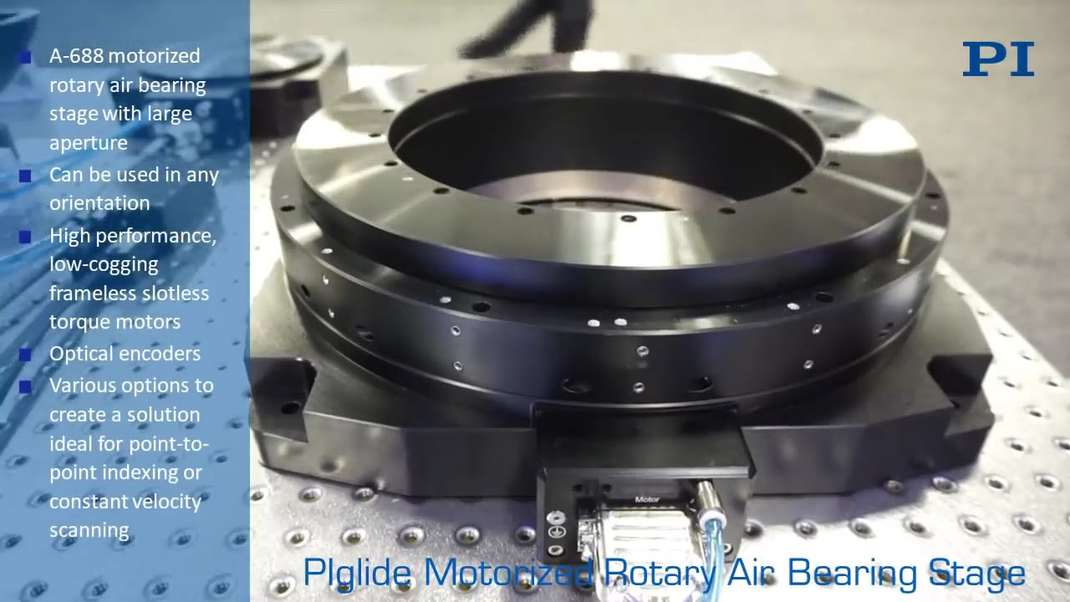

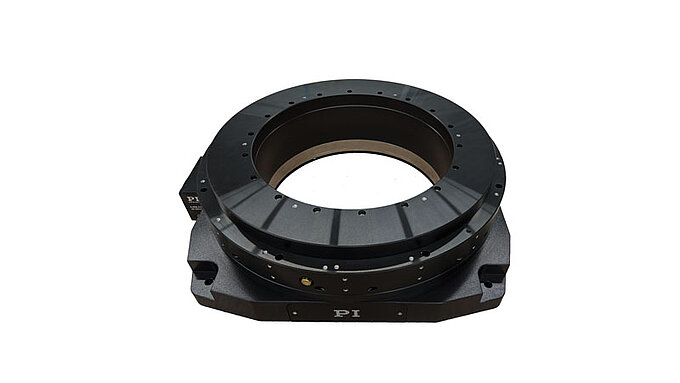

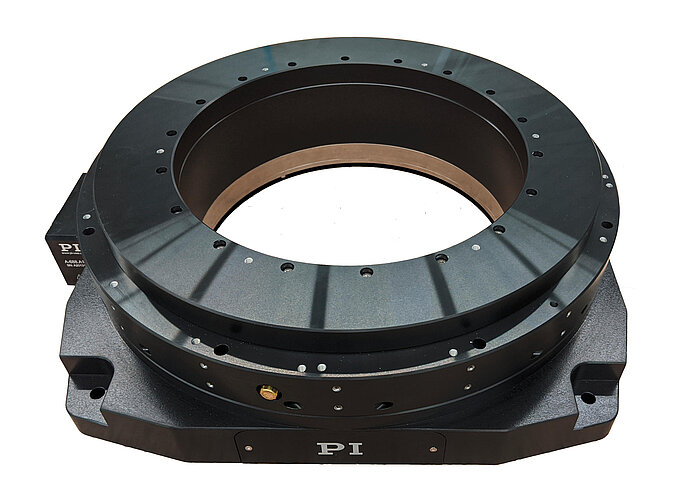

Precision Rotary Table with Direct Drive, Air Bearings and Large Aperture for Test, Metrology, and Precision Manufacturing

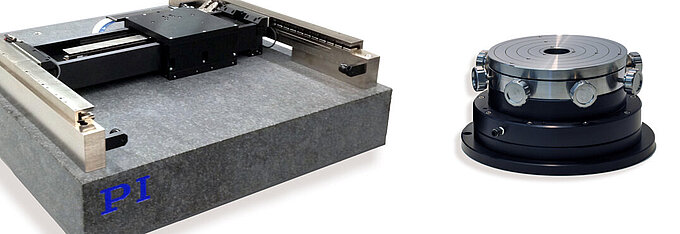

PI’s Direct Drive Air Bearing Rotary Tables (spindles) provide superior positioning and geometric performance, with absolute measuring feedback encoders for closed loop position control. The A-688 air bearing spindle offers a large ⌀260mm aperture for optical alignment, metrology, inspection, calibration, and scanning applications.

High Speed, High Precision, Maintenance-Free Nanopositioning Performance

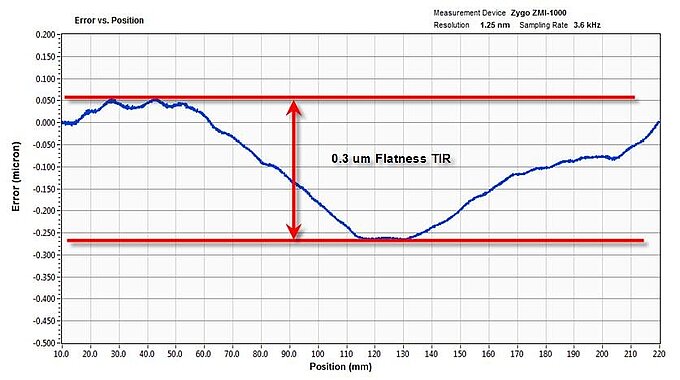

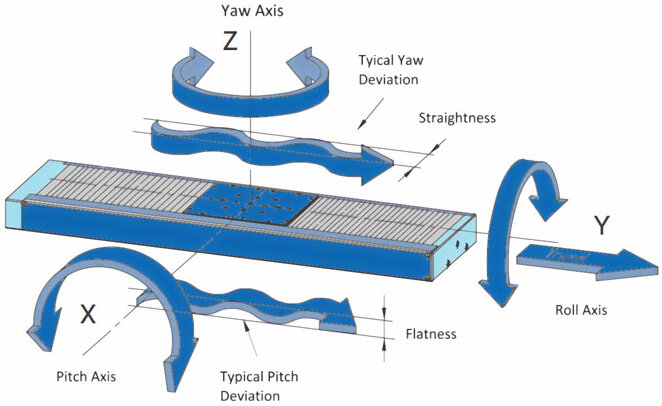

The A-688 direct drive rotary table with air bearings provides extremely high resolution and geometric performance. The angular resolution of this high precision air bearing spindle is 0.0015µrad (0.00003 arcsec), and flatness and eccentricity are specified better than 175nm and 300nm, respectively. This is made possible by high resolution, absolute measuring feedback encoders, and low-cogging frameless and slotless torque motors. The A-688 rotary table can be used in any orientation. Air bearing spindles guarantee a virtually unlimited service life with no wear, and zero required maintenance. As with all PI air bearings tables, the A-688 spindle is clean room compatible and requires no lubrication.

Closed-Loop Controller

PI uses EtherCat based, high performance motion controllers ideally suited for closed-loop control of the rotation tables. Advanced algorithms are available to deal with changing load conditions and to suppress external disturbances.

Features & Advantages

- High resolution: to 0.0015µrad

- High precision: Flatness / Eccentricity <175/300nm

- Minimized wobble: < 1 µrad

- Large aperture: ⌀260mm

- High load capacity: 77kg

- High velocity: to 500 RPM

- Direct drive for zero play

Why Use Rotary Air Bearing Spindles over Mechanical Rotation Stages?

Air-bearings have no traditional mechanical elements that can wear and deliver frictionless, non-contact motion, resulting in negligible reversal error, better flatness, and minimal wobble and eccentricity. All these are ideal prerequisites for applications such as inspection and metrology, calibration, and scanning of high-end parts (i.e., infrared and precision optics, turbine blades, shafts and bearings) in industries like aerospace, aircraft, automotive, semiconductors, and photonics. We also manufacture low profile precision rotary tables with air bearings.

Substantial Design and Manufacturing Experience, Standard and Custom Systems

PI designs and manufactures all air bearing products in the USA. PI’s engineering team has hundreds of man years of air bearing design and manufacturing experience. In addition to customized systems for OEMs, PI offers a substantial standard product line of air bearing stages that includes motorized and non-motorized, linear, rotary, spherical, X/XY, voice coil, compact, and large scale systems, as a complement to its existing comprehensive range of piezo nano positioning stages, traditional motorized positioners, and hexapod 6-axis parallel positioning systems. The extreme depth and breadth of motion technologies puts PI in the unique position to cover the whole motion range from finger-tip sized nano-positioners to large scale stages with long travel ranges, through a plethora of different drives and guiding systems that can be tailored to meet the needs of an OEM or customer.

Working with You

PI’s in-house engineered systems and components have enabled customers around the world to increase their productivity and technological advantage for 5 decades. With a large basis of standard precision motion products and proven methodologies, PI can quickly modify existing designs or provide a fully customized OEM solution to fit the exact requirements of the application.