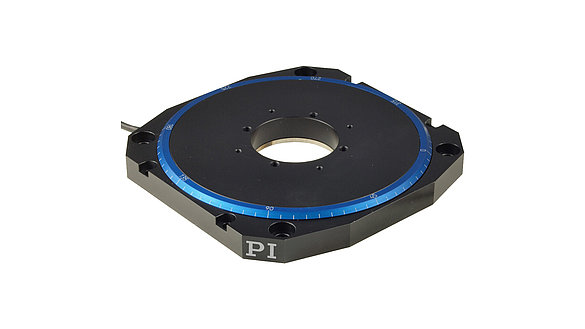

The ultra-low profile (0.6”) rotation stage is direct-driven, with a high-speed ceramic motor. It is based on PI’s proprietary PILine® ultrasonic motor technology.

Fast, Self Locking, Direct Drive, Direct Encoder

The M-660 precision rotation stage reaches top speeds of 720 degrees/sec. and resolution to 4 µrad. Its self-locking ceramic motor holds the position steady at rest, with no energy consumption and heat generation. A directly coupled precision optical encoder provides phase lag-free, backlash-free feedback to the servo controller.

Features & Advantages

- Max. Velocity 720 °/s, Unlimited Travel Range

- Low Profile: Only 15 mm (0.6”)

- Self-Locking Ceramic Direct Drive Motor: Energy Saving & High Position Stability

- Direct Metrology Precision Encoder, 4 µrad Resolution

- PILine® Drive: Non-Magnetic, Vacuum-Compatible Working Principle

- Compact Combinations with Linear Stages Available

Ceramic Drive used in the latest Generation Optical Instruments

The compact design with minimized mass and inertia provides high precision bidirectional speed and position control, as well as high speed motion contouring. The M-660 is based on the new U-641 Piezo Motor and outperforms the stability, acceleration and settling speed of traditional direct drive servo motors and gear-driven mechanisms. The innovative motor was also chosen by Leica Geosystems AG’s in their surveying instruments for geodesy, because it can provide significantly higher speeds, shorter positioning times and a very high positioning accuracy when moving the measuring optics.

Motion Controller / Software Support

A newly designed piezo motor motion controller is available to take advantage of the specific motion characteristics of ultrasonic ceramic motors. USB interfacing and a solid software and driver package for seamless integration are included.

Datasheets & Additional Information