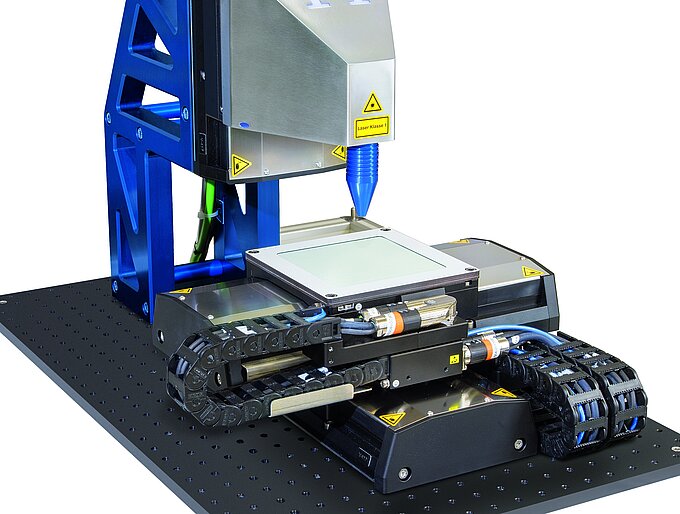

Low-profile, integrated 2-Axis linear stages provide high precision motion for industrial applications.

November 21, 2019: The V-700 and L-700 family of linear XY stages complements PI’s planar, ultra-high-precision air bearing XY stages. These integrated XY translation stages with mechanical bearings are engineered for higher loads or higher holding forces. They are offered with 3-phase linear direct-drive motors (smoother motion, higher speed and precision) and ball screws (higher push/pull forces and holding forces), respectively. Available with high accuracy linear encoders, these motorized XY linear stages are well-suited for applications in industrial automation, surface metrology, life-sciences, laser processing, and flat panel display testing.

Integrated Design

The integrated mechanical design allows for a lower profile and improved geometric performance, when compared to modular XY-stage assemblies of two single axis translation stages bolted together. Due to the improved support, planar XY tables are stiffer and flex less compared to XY-combinations of single axis linear stages, especially when the individual axes are moved to their extreme positions.

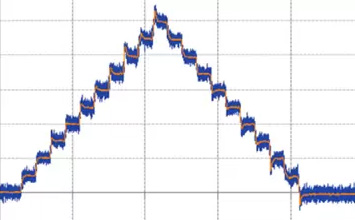

The ball-screw variants – L-731, L-738, and L-741 – can be powered by stepper motors and servo motors, respectively. The direct-drive, linear-motor variants – V-731, V-738, and V-741 – are driven by an ironless 3-phase motor for cogging-free ultra-smooth motion, for highest demands on precision. Ironless motors allow smoother, vibration-free running over a wide velocity range. Both 3 stage families provide sensor resolution from 0.1µm to 0.001µm, with mechanical position repeatability to 0.05µm.