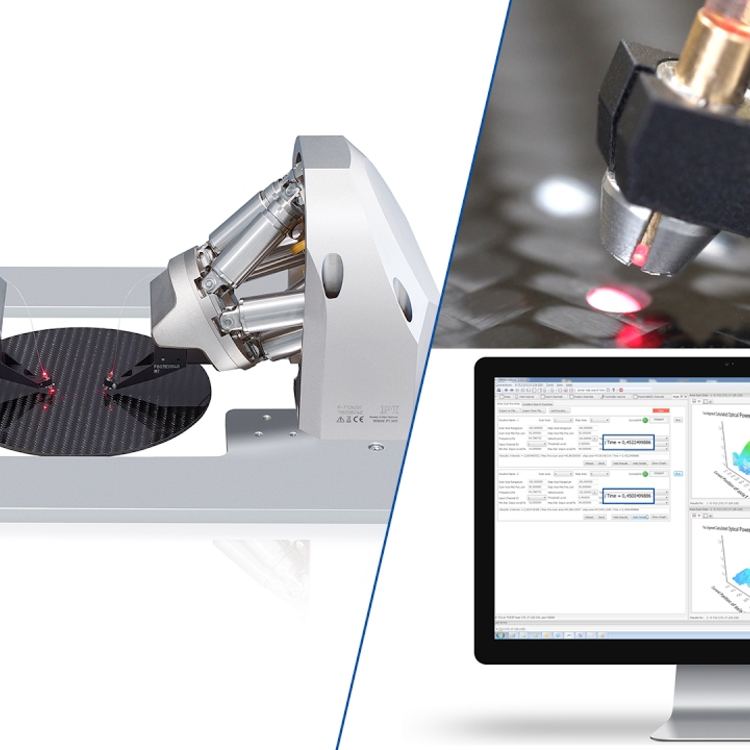

Single-sided photonics alignment system consisting of stacked XYZ linear positioners and NanoCube® nanopositioner; E-713 digital controller with 4 analog inputs; firmware routines for high-speed alignment tasks; software package

F-713.MAx Compact, High-Speed XYZ Photonics Alignment Systems

Single-Sided and Double-Sided, Fully Automated

- Integrated scan/align routines for fibers and photonic devices

- Fast, simultaneous optical performance optimization across multiple device I/Os and degrees of freedom

- Broad and deep software support for rapid process development, including support for popular languages such as C#, Python, LabVIEW, and MATLAB on Windows and Linux

- Automatic alignment in typically <0.5 s

- Responsive application and product support from PI worldwide

Problem solved

PI's Fast Multichannel Photonics Alignment (FMPA) solutions combine application-optimized, fab-ready, highly dynamic alignment stages with sophisticated controllers that integrate the world's most advanced and effective first-light search, profile, and power optimization alignment algorithms.

Reduction of alignment time by 99%

This award-winning technology addresses the number one cost driver for photonics test and assembly: the precise alignment required for each element and channel. Legacy alignment technologies date back to the 1980s and can take minutes to complete. PI's fast optical alignment solutions reduce the time required by typically 99%, routinely completing the task in less than one second. Studies show that up to 80% of the cost of a photonic device is attributable to alignment, without FMPA. If this 80% share of costs is reduced by 99%, the benefits to the manufacturing industry are obvious. And with projections of three orders of magnitude escalation in demand for photonic devices in the near future, as new applications and devices emerge, FMPA is a true enabler.

Compact solution for XYZ alignment challenges

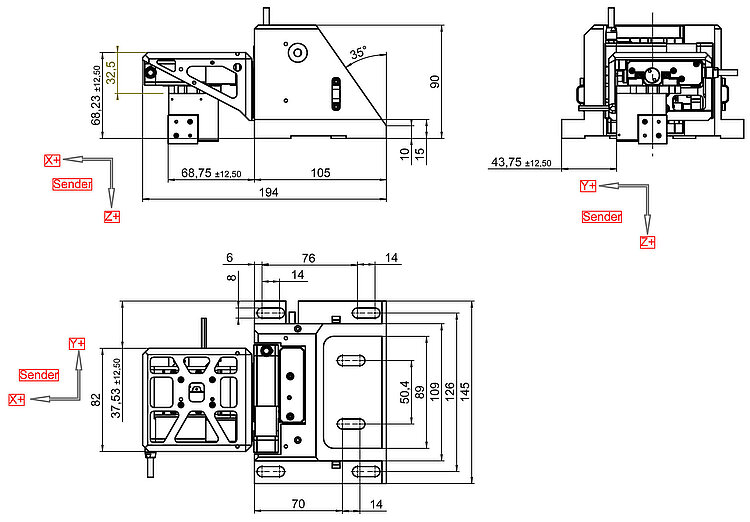

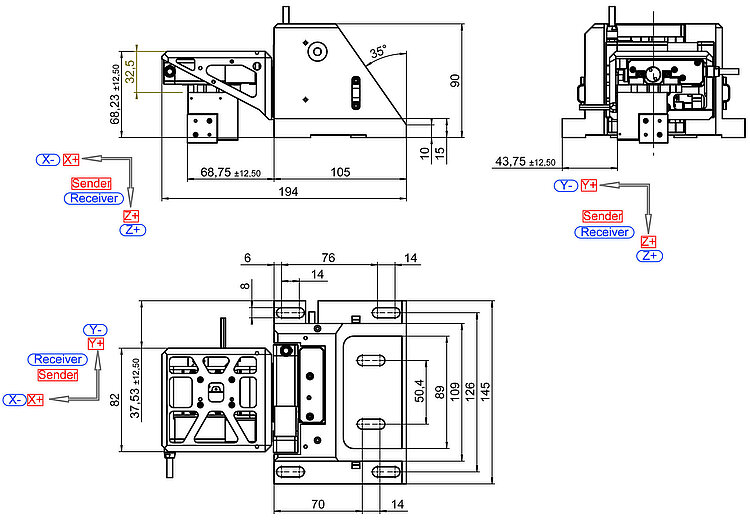

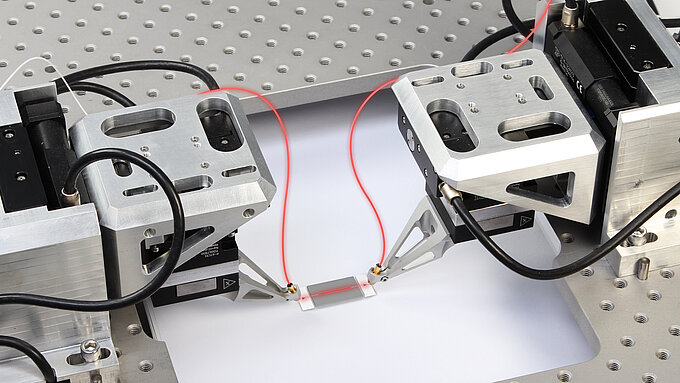

This compact solution integrates a high-precision XYZ stage (based on model M-122) for generous travel with an XYZ piezo nanopositioner of extraordinary speed and resolution (based on model P-616). A single controller manages all axes in single-sided and double-sided configurations: F-713.MA1 and F-713.MA2. Four high-resolution analog inputs provide connectivity to power meters, such as PI’s F-712.PM1 high-bandwidth optical power meter, for optimization and profiling, enabling efficient and fast automated fiber alignment. Soft limits are supported to ensure process safety. Starting with these sophisticated platforms, it is easy to configure automated alignment solutions of unprecedented speed that support functionalities such as submicron-sensitive wafer proximity automation.

Application fields

PIC production; photonics alignment; alignment of optical components or lenses; silicon photonics wafer probing; testing, assembly, and packaging of photonics and fiber optics

Specifications

Specifications

| Motion and positioning | F-713.MA1 | F-713.MA2 | Tolerance |

|---|---|---|---|

| Number of active axes | 6 | 12 | |

| Active axes, rough positioning | X ǀ Y ǀ Z | X ǀ Y ǀ Z | |

| Travel range in X, rough positioning | 25 mm | 25 mm | |

| Travel range in Y, rough positioning | 25 mm | 25 mm | |

| Travel range in Z, rough positioning | 25 mm | 25 mm | |

| Minimum incremental motion in X, rough positioning | 3 µm | 3 µm | |

| Minimum incremental motion in Y, rough positioning | 3 µm | 3 µm | |

| Minimum incremental motion in Z, rough positioning | 3 µm | 3 µm | |

| Maximum velocity in X, rough positioning, unloaded | 20 mm/s | 20 mm/s | |

| Maximum velocity in Y, rough positioning, unloaded | 20 mm/s | 20 mm/s | |

| Maximum velocity in Z, rough positioning, unloaded | 20 mm/s | 20 mm/s | |

| Drive type, rough positioning | DC motor | DC motor | |

| Guide | Crossed roller guide | Crossed roller guide | |

| Sensor type, rough positioning | Rotary encoder | Rotary encoder | |

| Active axes, fine positioning | X ǀ Y ǀ Z | X ǀ Y ǀ Z | |

| Travel range in X, fine positioning | 100 µm | 100 µm | |

| Travel range in Y, fine positioning | 100 µm | 100 µm | |

| Travel range in Z, fine positioning | 100 µm | 100 µm | |

| Minimum incremental motion in X, open-loop, fine positioning | 0.3 nm | 0.3 nm | |

| Minimum incremental motion in Y, open-loop, fine positioning | 0.3 nm | 0.3 nm | |

| Minimum incremental motion in Z, open-loop, fine positioning | 0.3 nm | 0.3 nm | |

| Minimum incremental motion in X, closed-loop, fine positioning | 2.5 nm | 2.5 nm | |

| Minimum incremental motion in Y, closed-loop, fine positioning | 2.5 nm | 2.5 nm | |

| Minimum incremental motion in Z, closed-loop, fine positioning | 2.5 nm | 2.5 nm | |

| Linearity error in the nominal measuring range | 2 % | — | max. |

| Bidirectional repeatability in X, 10 % travel range | 2 nm | 2 nm | typ. |

| Bidirectional repeatability in Y, 10 % travel range | 2 nm | 2 nm | typ. |

| Bidirectional repeatability in Z, 10 % travel range | 2 nm | 2 nm | typ. |

| Drive type, fine positioning | PICMA® | PICMA® | |

| Sensor type fine positioning | Incremental linear encoder | Incremental linear encoder | |

| Adjustment | F-713.MA1 | F-713.MA2 | Tolerance |

| Scanning time of spiraled area scan 10 µm Ø | < 0.2 s | < 0.5 s | typ. |

| Scanning time of spiraled area scan 100 µm Ø | < 0.3 s | < 1 s | typ. |

| Scanning time of spiraled area scan 500 µm Ø | < 3 s | < 6 s | typ. |

| Signal optimization with gradient search, randomized with ±5 μm (repeatability < 0.01 dB) | 0.3 s | 0.3 s | |

| Requirements for the optical power meter | F-713.MA1 | F-713.MA2 | Tolerance |

| Output signal | Analog output, ideally converted from linear to logarithmic | Analog output, ideally converted from linear to logarithmic | |

| Maximum output voltage range | -5 to 5 V | -5 to 5 V | max. |

| Minimum bandwidth | 1 kHz | 1 kHz | min. |

| Maximum noise level | -60 dBm | -60 dBm | max. |

Note on linearity error: no polynomial linearization

Scanning time: typical time span for scanning the entire area and moving to the highest intensity

Signal optimization with gradient search: reaching the global maximum after first light has been found

Note on operating temperature range: specification applies to mechanics; operating temperature range for controller: 5°C to 40°C

Ask about customized versions

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Datasheet

Documentation

User Manual F713T0016

Fast Multi-Channel Photonics Alignment of Silicon Photonics Components with F-713 Alignment Systems and Hexapods from PI. PILightning Option for First Light Search

3D Models

F-713.MAx 3D Model

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Double-sided photonics alignment system consisting of stacked XYZ linear positioners and 2 NanoCube® nanopositioners; E-713 digital controller with 4 analog inputs; firmware routines for high-speed alignment tasks; software package

How to Get a Quote

Questions? - Ask a PI Engineer

Technology

Active Alignment

The need to align devices down to nanoscale accuracy is arising in many fields. Optical components such as the lenses or lens assemblies in small cameras, or even the CCD chip itself, need to be positioned with ever more precision.

Hexapods and SpaceFAB

Hexapods are systems for moving and positioning loads in six degrees of freedom, in three translational and three rotational axes.