PI Ceramic - PI’s ISO 9001 certified subsidiary - fully integrates research, development and manufacturing of

Piezo Components/Transducer Selections

- Piezo Tranducers, Ultrasonic Transducers

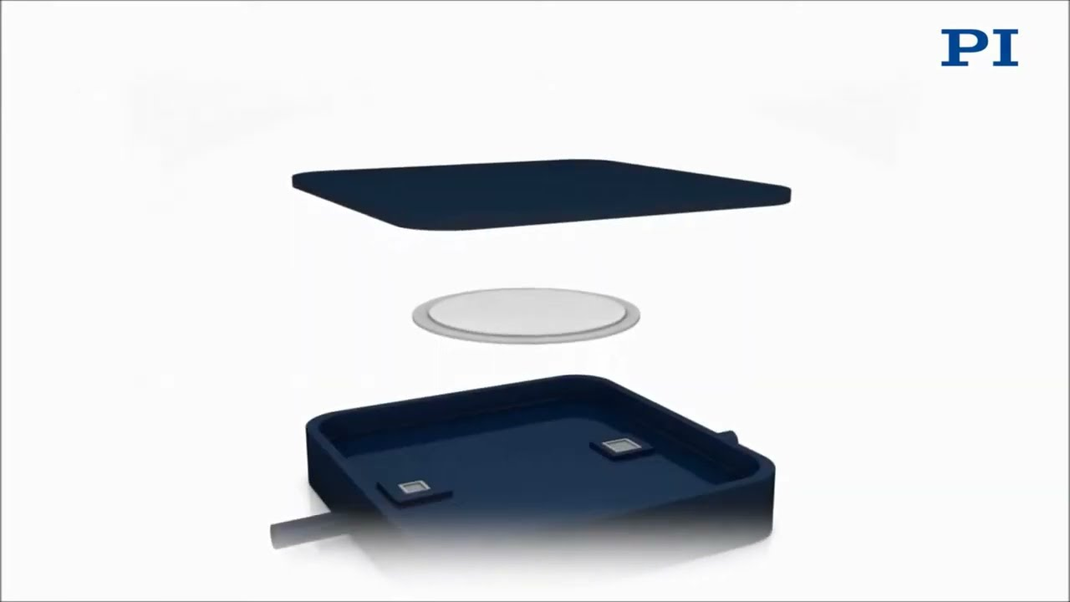

- Piezo Assemblies for Metering

- Piezoelectric and Dielectric Ceramics

- Multilayer Actuators

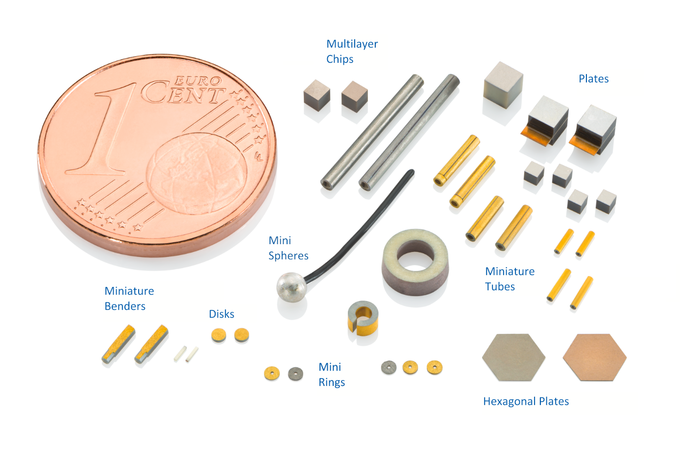

- Piezo Rings, Tubes, Discs and Plates

- Ultrasonic Transducers

- Piezo Motors

State-of-the-Art Fabrication Equipment

- Film Casting

- Ceramic Grinding and Polishing

- Vacuum Coating

- Pressing

- Custom Dimensionss

- Custom Ceramics

- Custom Coatings

- Custom End-Pieces

- Custom Casings

With our in-house ceramics manufacturing capabilities at PI Ceramic we are in a position to offer custom Piezo stack translators, benders, shear actuators and tubes for almost any OEM application. If the right solution is not in this catalog, contact your local PI representative.

Piezoceramic Materials

A wide selection of high quality Lead Zirconate Titanate (Piezo) materials are offered to suit many applications. Discs, Plates, Tubes, Rings and Shear Plates in a variety of standard and custom form factors are available from the following materials (please ask for special data sheets):

PIC 140

PIC 140 piezoceramic material offers high mechanical stability and polarization resistance in combination with a high mechanical Q and high Curie Point. Applications are in the field of power ultrasonics, sound navigation and ranging or medical diagnostics.

PIC 141

PIC 141 piezoceramic material offers high electromechanical coupling factors with reasonable mechanical Q, good mechanical stability, and resistance to high electrical fields.

PIC 151

PIC 151 piezoceramic material offers the highest piezoelectric coupling factor and very high dielectric and piezoelectric constants. It is especially suited for micropositioning components, low-frequency ultrasonic transducers, buzzers and ultrasonic speakers.

PIC 155/PIC 255

PIC 155/PIC 255 piezoceramic material offers a high piezoelectric coupling factor, low mechanical Q and minimal response of the dielectric constants to temperature changes. The material is especially suited for low-frequency ultrasonic transducers in pulse mode, for transmission and reception over a wide temperature range and special actuator applications.

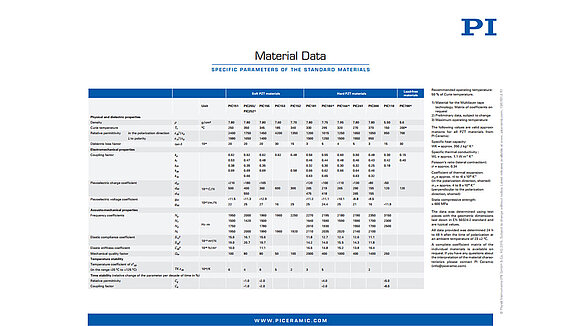

| TECHNICAL DATA: | |||||

Piezo Characteristics | PIC 140 | PIC 141 | PIC 151 | PIC 155 | PIC 255 |

Density [g/cm³] | 7.60 | 7.80 | 7.80 | 7.70 | 7.8 |

Curie Temperature [°C] | 330 | 275 | 250 | 345 | 350 |

Dielectric Constant eT33 / e0 | 1200 | 1300 | 2100 | 1500 | 1750 |

Dielectric Constant eT11 / e0 | 680 | 1500 | 1980 | 1400 | - |

Dielectric Loss (tan d [x 10-3]) | 10 | 5 | 15 | 20 | 15 |

Resistivity [W m] | 1010 | 1010 | 1011 | 1011 | - |

Coupling Factors | |||||

kP | 0.50 | 0.58 | 0.62 | 0.62 | 0.62 |

k33 | 0.60 | 0.66 | 0.69 | 0.69 | 0.35 |

k31 | 0.25 | 0.31 | 0.34 | 0.35 | 0.69 |

Mechanical Q | 350 | 1250 | 120 | 80 | 80 |

Frequency Constants [Hzm] | |||||

NP | 2200 | 2200 | 2100 | 1950 | 2000 |

N1 | 1680 | 1610 | 1500 | 1430 | 1420 |

N3 | 1800 | 1925 | 1680 | - | - |

Nt | 2100 | 2050 | 1950 | 1985 | 2000 |

Charge Constants [x 10-12 m/V] | |||||

d31 | - 60 | - 140 | - 210 | - 165 | -180 |

d33 | 200 | 310 | 450 | 360 | 400 |

d15 | 265 | 475 | 580 | 520 | 560 |

Voltage Constants [x 10-3 Vm/ N] | |||||

g31 | - 8.5 | - 13.1 | - 11.5 | -12.4 | -11.3 |

g33 | 28.2 | 29.0 | 22.8 | 27.0 | 25.1 |

Elastic Constant [x 10-12 m²/N] | |||||

S11E | 11.7 | 12.4 | 15.0 | 15.6 | 16.1 |

S33E | 11.7 | 13.0 | 19.0 | 19.7 | 20.7 |

Aging Rate [% per Time Decade] | |||||

Cf | + 0.3 | + 0.3 | +0.2 | +0.15 | +0.13 |

Ck | |||||

This is a legacy product that may have limited availability or may have been replaced. Ask a PI engineer for an equivalent new model.