For updated product information, see the latest specs and order info.

- ±1mrad θX and θY Tilt Range

- For Mirrors to 50 mm Ø

- Sub-µrad Resolution

- Closed Loop Versions

- Differential Design for Excellent Temperature Stability

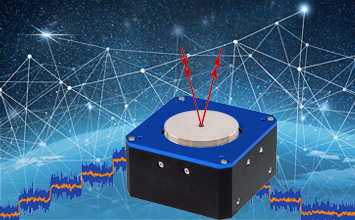

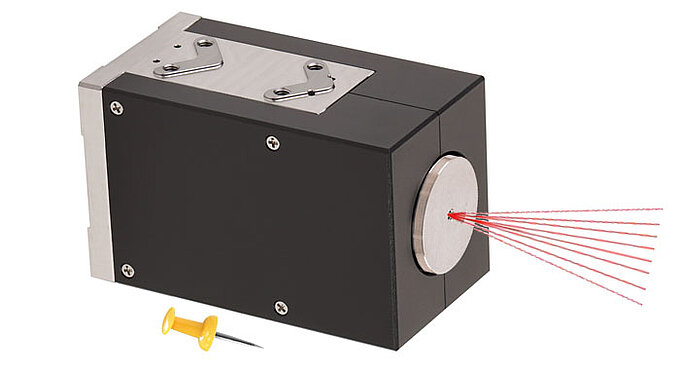

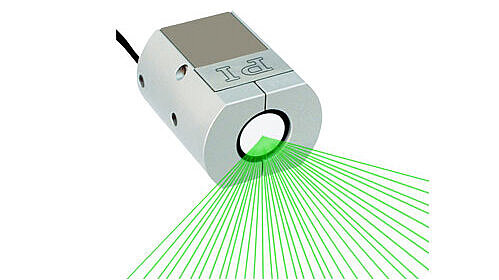

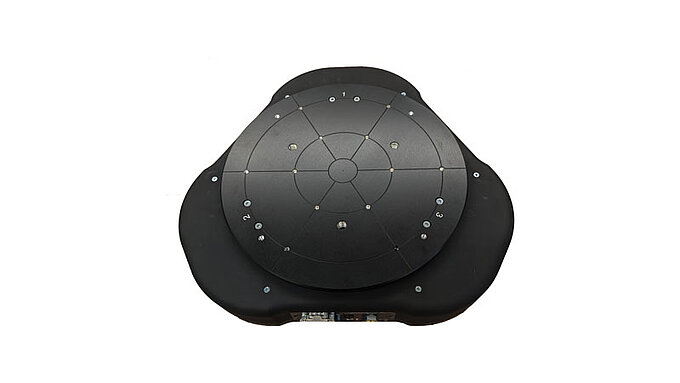

S-330 are ultra-fast, high precision laser beam steering mirror platforms based on high speed piezo drives. These compact tilt stage units provide high resolution, high repeatability, and highly dynamic angular movements of the top platform in two orthogonal axes. The tilt angle range is ±1mrad (each axes) with sub-µrad resolution, longer tilt range models are available. Closed loop servo control feedback versions provide the highest accuracy and repeatability and precision. S-330 laser beam steering systems are designed for laser mirrors up to 50 mm diameter and have outstanding angular stability over a wide temperature range. To match the CTE of Zerodur glass, the high-performance S-330 mirror tilters are available with an Invar top platform.

A) Piezo Driver Electronics for High Speed, High Dynamics Applications

E-500 Chassis with 2 x standard and 1 x specially configured E-505.00 High Voltage Piezo Amplifier Modules, optional specially configured E-509.S3 Position Servo Controller Module.

B) Piezo Driver Electronics for Static and Medium Dynamic Applications

E-500 Chassis with specially configured E-503.00 Amplifier Module, optional specially configured E-509.S3 Position Servo Controller Module (required for closed loop operation, see "Piezo Control Electronics" section for details).

Application examples:

Free space optical laser communication, Image stabilization, laser beam stabilization, precision optical dithering, adaptive optics systems, laser beam steering & scanning, correction of polygon scanner errors.

For larger tip/tilt angles, voice coil steering mirrors are also available.

Working principle:

S-330 Tilt Platforms are equipped with two pairs of ultra-reliable multilayer piezoelectric linear drives (0 to 100 V) operating in push/pull mode. The stainless steel case is equipped with an integrated, FEA (Finite Element Analysis) modeled circular flexure featuring zero stiction/friction and exceptional guiding precision.

In open loop operation, the platform angle roughly corresponds to the drive voltage. The open loop model is ideal for applications where the position is controlled by an external loop based on data provided by a sensor (e.g., quad cell, CCD chip, ...).

The closed loop tip/tilt stage version is equipped with two pairs (one per axis) of Strain Gage sensors operated in a bridge circuit for ultra-high resolution and angular stability. They provide sub-µrad resolution and repeatability (with PI control electronics).

ORDERING INFORMATION:

S-330.10 θX and θ Y Piezo Laser Steering Mirror Tilt Platform ±1 mrad, Strain Gage Sensor

S-330.30 θ X and θ Y Piezo Laser Steering Mirror Tilt Platform ±1 mrad

| TECHNICAL DATA: | ||||

Models | S-330.30 | S-330.10 | Units | Notes |

Active axes | q X,q Y | q X,q Y | ||

Open loop tilt angle @ 0 to 100 V | ±1 | ±1 | mrad ± 20 % | A2 |

Closed loop tilt angle ³ | - | ±1 | mrad | A3 |

Integrated feedback sensor | - | 4 x strain gauge | B | |

Closed / open loop ** resolution £ | - / 0.05 | 0.1 / 0.05 | µrad | C1 |

Closed loop linearity (typ.) | - | ± 0.2 | % | |

Full range repeatability (typ.) | - | ± 2 | µrad | C3 |

Electrical capacitance | 3.6 / axis | 3.6 / axis | µF ± 20 % | F1 |

* Dynamic operating current coefficient (DOCC) | 0.22 / axis | 0.22 / axis | µA/(Hz x µrad) | F2 |

Resonant frequency (f0) without mirror | 3.3 | 3.3 | kHz ± 20 % | G2 |

Resonant frequency w/ Æ 25 x 8 mm glass mirror | 2.4 | 2.4 | kHz ± 20 % | G3 |

Distance pivot point to platform surface (T) | 6 | 6 | mm | |

Platform moment of inertia | 1530 | 1530 | gmm² | |

Operating temperature range | - 20 to 80 | - 20 to 80 | ° C | H2 |

Voltage connection | 3 x VL, 2 m cable | 3 x VL, 2 m cable | J1 | |

Sensor connection | - | 1 x L, 2 m cable | J2 | |

Weight (w/o cables) | 200 | 200 | g ± 5 % | |

Material (case / platform) | N-S / I | N-S / I | L | |

* Dynamic Operating Current Coefficient in µA per Hertz and µrad. Example: Sinusoidal scan of 100 µrad at 10 Hz requires approximately 0.22 mA drive current.

** Noise equivalent motion with E-503 amplifier.

For updated product information, see the latest specs and order info.

This is a legacy product that may have limited availability or may have been replaced. Ask a PI engineer for an equivalent new model.