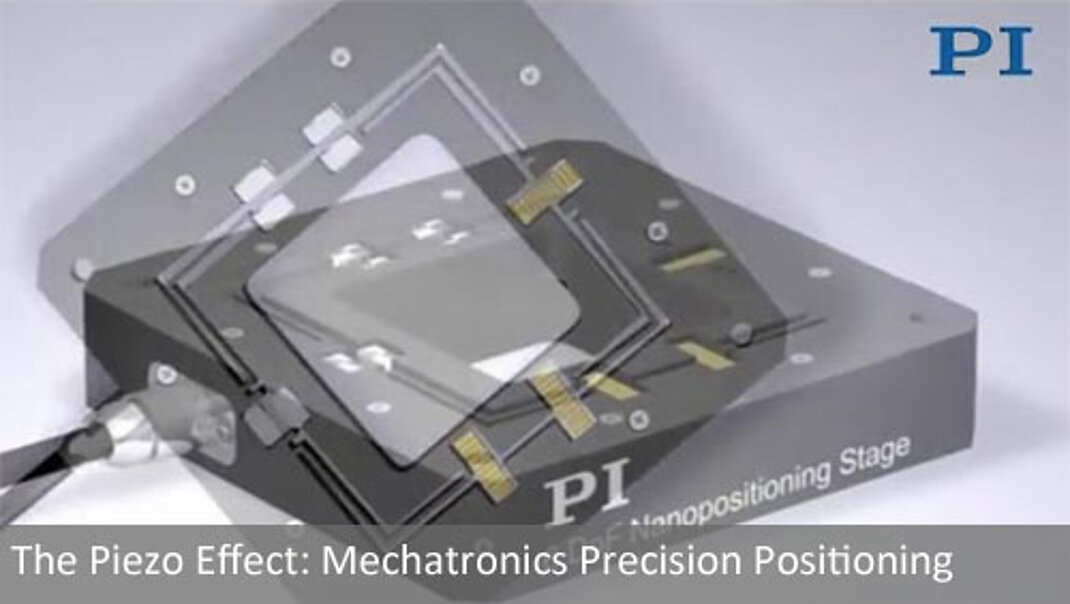

How Does a Piezo Flexure Stage Work - Why use Piezo Nanopositioning Stages?

Nanopositioning Devices with High Dynamics and Precision

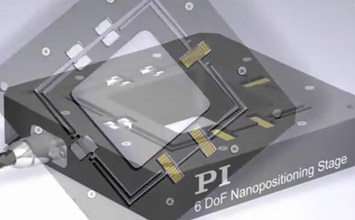

Piezo flexure stages make use of the piezoelectric effect, a mechanical flexural guiding system and often an additional motion amplifier. Piezo stages also called nanopositioners, nanopositioning stages, and piezoelectric flexure. Piezo mechanical devices such as flexure stages were developed for high precision nanopositioning applications in the semiconductor industry, for super-resolution microscopy and photonics alignment applications. The piezo flexure stage integrates a piezoelectric stack actuator as the driving force. Piezo stages are available as in single axis or multi-axis designs, up to 6 six-axis nanopositioning stages.

Feedback Sensors for Closed-Loop Operation

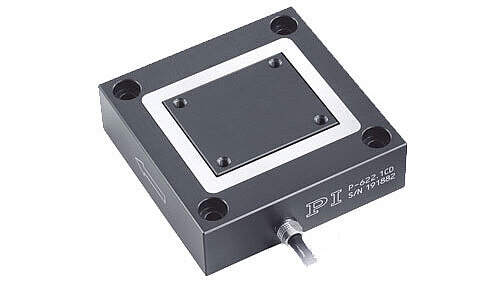

In order to provide smooth and highly repeatable nanopositioning, a nano-precision measuring sensor needs to be integrated in the flexure stage for closed-loop feedback with nanometer accuracy. Short distance nanopositioning applications are best served by piezo stages, due to their extreme precision. For longer travel ranges, air bearing stages are ideal. PI started designing and manufacturing flexure stages with high precision EDM cut hinges back in the 1980s and has delivered hundreds of thousands of standard and custom systems since then. If designed well, the flexure hinges guide the moving platform with exceptional straightness in the nanoradian range. The stages are operated with high performance digital closed-loop feedback controllers and provide very high velocity, rapid step and settle, very high linearity, and nanometer range accuracy and resolution.

Why PI Nanopositioning Stages Provide Higher Performance:

- Several Decades of Experience in Designing Flexure NanoPositioning Stages

- Hundreds of different Standard and Custom Models

- High Quality Piezo Ceramics from PI's own Piezo Ceramics Factory

- Largest Variety of Controllers (Digital, Analog, High Speed, High Power, OEM....)

- State-of-the-Art Metrology Lab: Thermical, Acoustical, Seismical Isolation

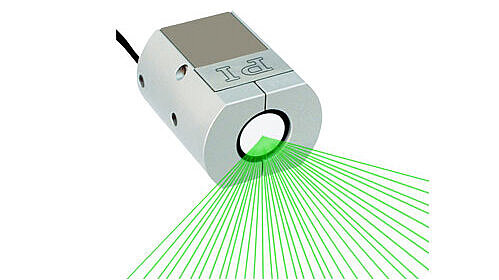

- Own Capacitance Sensor Design & Manufacturing

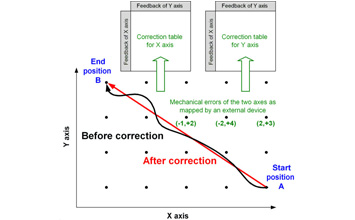

- Active Trajectory Control

- Advanced Control Algorithms for Highest Throughput

PI provides the broadest and deepest portfolio of precision motion technologies and offers the widest selection of single and multi-axis Piezo Flexure Nanopositioning Stages & Scanners world-wide.

In addition to piezo nanopositioning stages, PI also offers air bearing stages and linear motor stages with nanopositioning resolution.

PI Piezo Flexure Stages and NanoPositioners offer the highest precision of all nanopositioning systems on the market. Key features are active and passive precision trajectory control (sub-nanometer, sub-µrad straightness & flatness), sub-nanometer resolution and stability, 1 to 6 degrees of freedom, ultra-responsive mechanics, and control electronics for enhanced throughput.

PI Flexure NanoPositioners are superior to traditional positioners (ball bearings, crossed roller bearings, etc.) in terms of resolution, accuracy, straightness, and flatness. Due to the inherent friction, traditional positioners are limited to applications requiring repeatability on the order of 0.5 to 0.1 µm, while PI Flexure NanoPositioners can easily achieve resolution and repeatability in the nano- meter realm and below.

Application examples of PI Piezo Flexure NanoPositioners are:

- Metrology

- Disk Drive Testing

- Nanopositioning

- Semiconductor Test Equipment

- Lithography

- Wafer Steppers

- Mask Alignment

- Precision Machining

- (Out-Of-Roundness Turning, Boring, Grinding)

- Scanning Interferometry

- Surface Structure Analysis

- Scanning Microscopy

- Autofocus Systems

- Bio-Technology

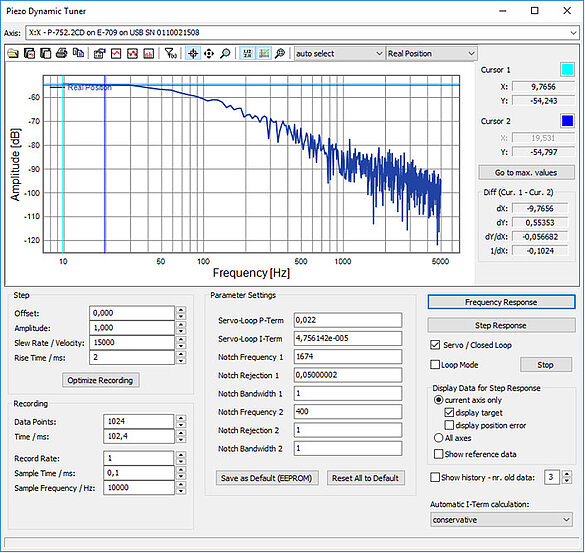

Motion Software for Piezoelectric Nanopositioning Stages

Piezo controllers come with special software for tuning, optimization, and programming of motion paths or patterns in one or more degrees of freedoms. PI nanopositioning stages are delivered with preconfigured operating parameters. The best parameters, found in the factory during the calibration probes, are stored on the controller in an ID chip and are automatically uploaded to the controller when connected.

Modern digital piezo controllers are superior to analog controllers and the latest designs provide digital and analog control inputs, high speed EtherCat, SPI interfaces, and simple analog interfaces for user communication. The closed-loop nanopositioning controller compares the feedback signal of the piezo stage integrated sensor and automatically adjusts the output voltage until the desired position is achieved. This happens in milliseconds. -Closed-loop piezo controllers increase stiffness and eliminated hysteresis effects and creep effects known from open-loop piezo actuators.

Long travel piezo stages can achieve travel to 2mm and piezo motor stages can achieve hundreds of millimeters.

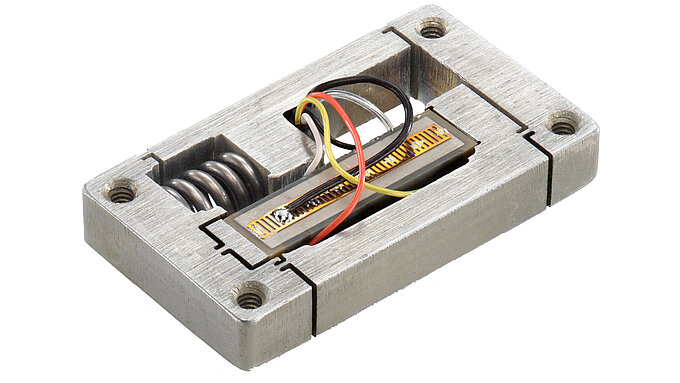

Flexure guided stages often use amplified piezo actuators to provide longer travel than a piezo stack would usually provide. The latest patented PICMA® piezo actuators were tested to last over 100 Billion Cycles for the Mars mission and provide superior reliability in industry and space applications. When flexures are designed with proper experience and Finite Element Analysis (FEA), they can virtually last forever.

PI provides piezo Nanopositioners in hundreds of different sizes and configurations, many shapes and sizes, used in a variety of applications from semiconductor metrology to fast dispensing.