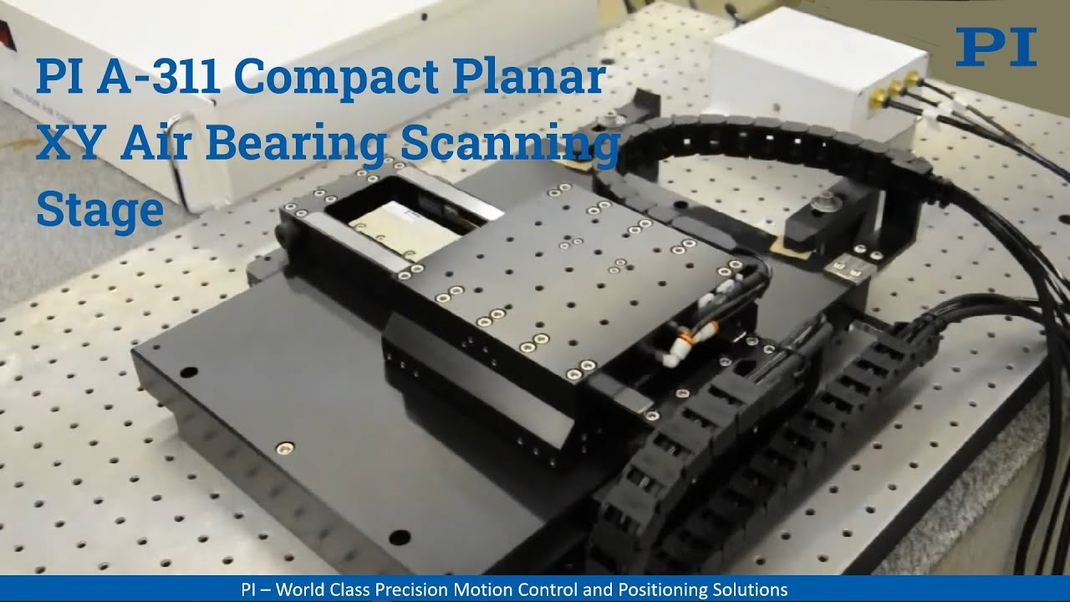

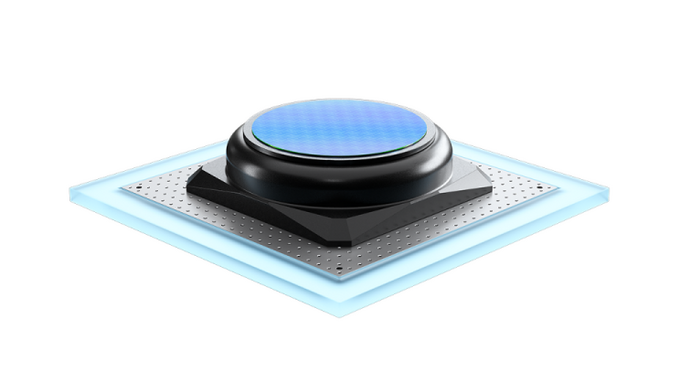

This high performance, XY metrology table was designed for industrial precision applications such as surface metrology where 2-axis precision linear translation is required. Applications for precision motorized XY-stages include surface metrology, materials research, topographical measurements in semiconductor test & inspection, flat-panel manufacturing as well as optical inspection of precision machined parts.

For use in the above mentioned fields, extreme straightness and flatness of motion and high dynamics are essential. During the development, PI miCos focused on combining industrial robustness with very high accuracy and precision as well as a high load bearing capacity. The positioning system can handle loads to 45lbs and still provide resolution as high as 5 nanometers and repeatability of 0.2µm thanks to its novel PIOne interferometric linear encoder. Even 1nm resolution is feasible with reduced maximum speed.

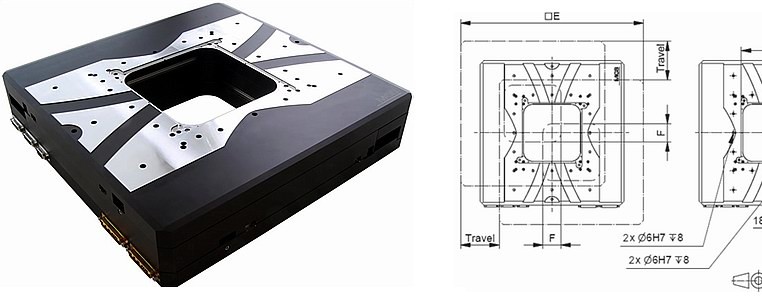

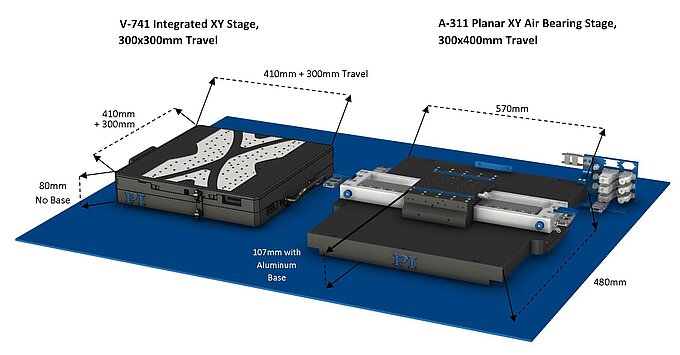

The integrated, low profile XY stage provides 4" travel range in two orthogonal axes and achieves ± 2 µm straightness and flatness of motion and yaw of only ± 20 µrad and pitch of ± 40 µrad. Higher performance is available with planar air bearing XY stages.

Several motor options are available. For applications where closed-loop operation is not required, open-loop stepper motors are offered. Several closed-loop versions are available for higher demands: stepper motors, DC servo motors, and direct drive linear motors.

Several high-performance motion controllers with EtherCat® industrial communication standards are available from PI. The motorized XY precision metrology stage can be combined with rotational stage axes and goniometric axes as well.