Industrial Optical Inspection

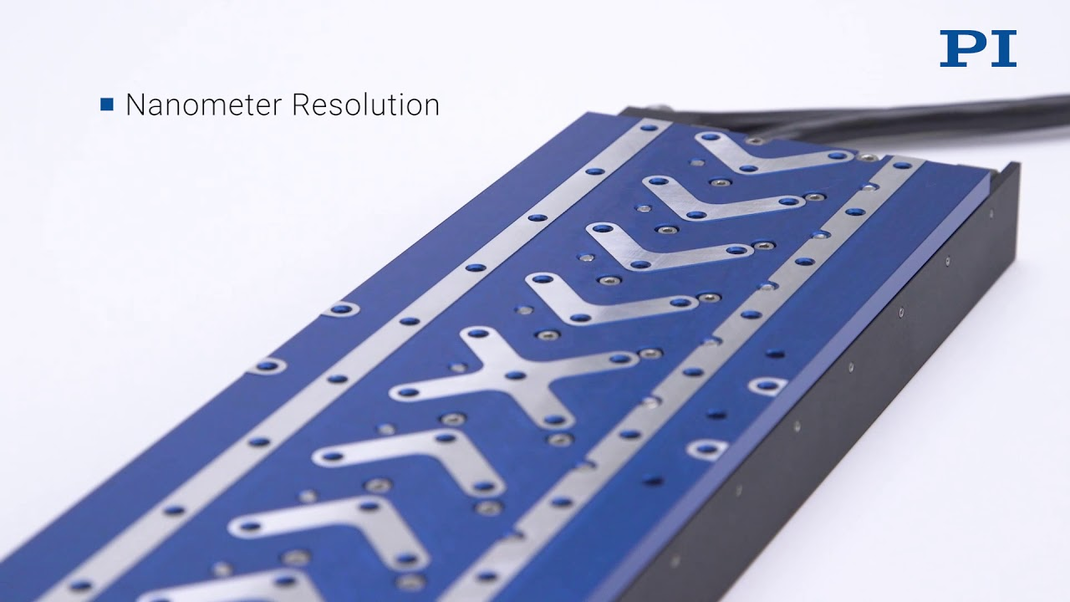

Flexible Configuration – Fast Step- and-Settle – Nanometer Resolution

Optical inspection is an essential process in industrial quality assurance. Optical inspection systems, which are used in industrial environments, should provide reliable and repeatable measurement results and enable high throughput rates. This also applies to the movement of the workpiece, specimen or test specimen, and to the positioning of the imaging optics. The positioning systems used, must be flexible in order to move the sample in the plane along different travel ranges and the optical components in the vertical direction.

Key Features of the Positioning Solution

Flexible Configuration

High repeatability and nanometer precision

High-resolution position sensors

Measuring using auto-focus algorithms

Focusing on different focal planes

Flexible adaptation to the required performance characteristics through PIMag® Motors

Easy integration into the automation environment via industrial EtherCAT® Interface

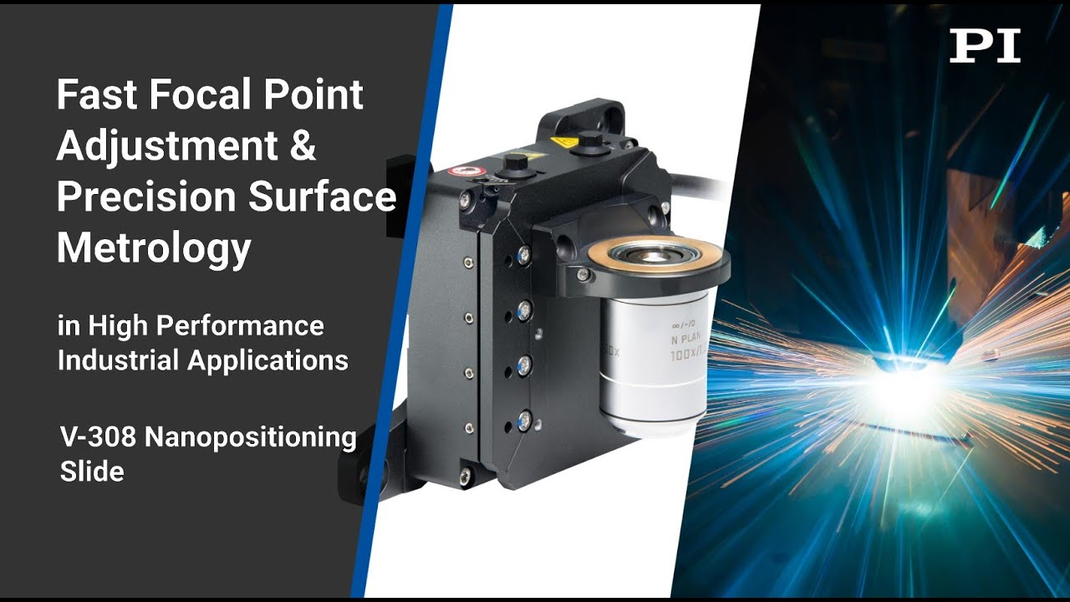

Positioning of the Imaging Optics

- High scanning speed and fast step-and-settle due to magnetic plunger coil drive

- Adjustable weight compensation for flexible lens masses

- High-resolution, direct-measuring position sensors

- Flexible adaptation of drive force and dimensions due to PIMag® voice coil motors

>> V-308 Fast Focus Z-Stage

Sample Positioning

- High scanning speeds due to magnetic linear motors

- Serial axis combinations for flexibly configurable travel ranges on the sample level or integrated XY stages for space-saving design

- Flexible adaptation of drive force and dimensions due to PIMag® linear motors

- High-resolution, direct-measuring position sensors

>> V-508 PIMag® Precision Linear Stage

Motion Control

- Optional industrial EtherCAT® interface

- Digital control with optimized control algorithms for constant scanning speed, high repeatability, and fast step-and-settle

- Fast sensor signal processing for simultaneous high speeds with high resolution

- Optional analog inputs for external control signals