Automation and Microscopy: Faster Test & Measurement, Surface Metrology – Piezo Speed is Enabler for 100% Testing

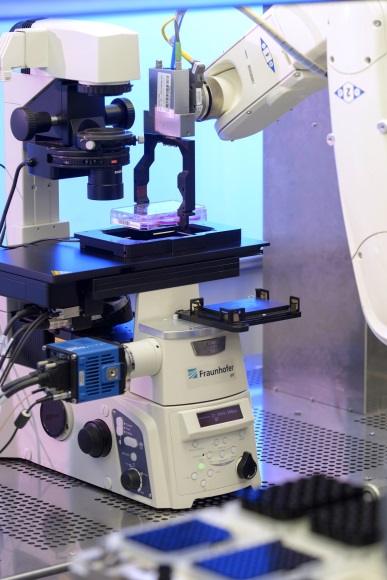

Everybody who commutes by car is familiar with the concept: constant velocity gets you faster to your destination than stop-and-go traffic. This well-known principle from the macro-world is now employed in the nano-world by scientists from the Fraunhofer Institute for Production Technology IPT in Aachen, Germany.

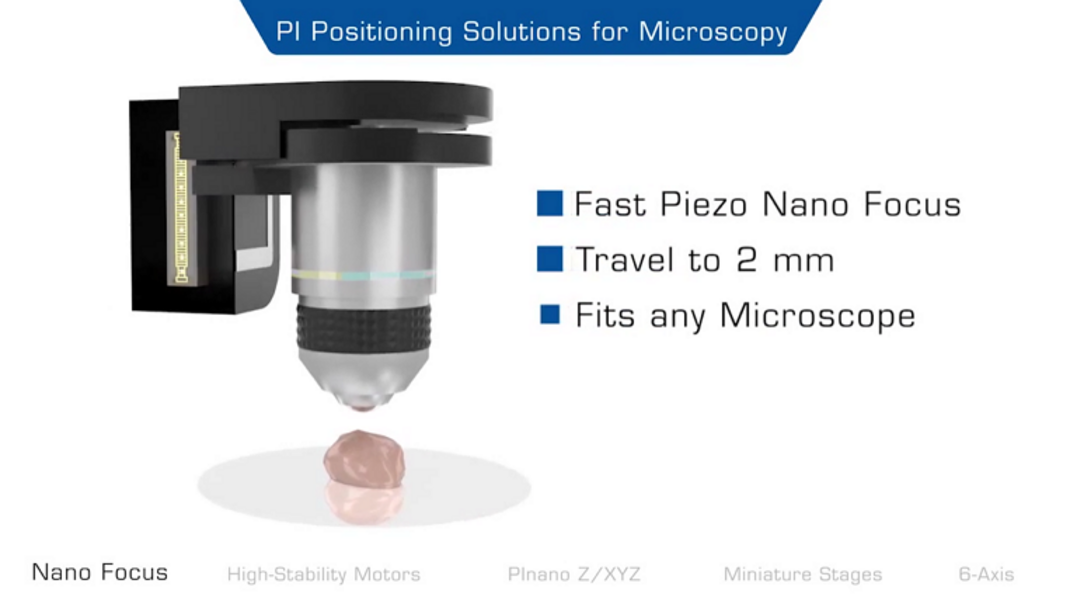

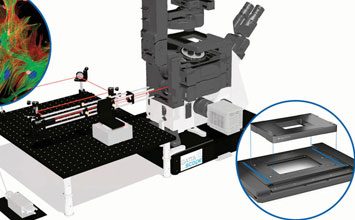

Their solution speeds up microscopic testing of large-surface objects, such as well plates, and enables 100% testing for the first time. A fast nano-focus device based on a piezo-ceramic actuator embedded in a flexure guided lens positioning mechanism from PI (Physik Instrumente) is one of the driving forces for this success.

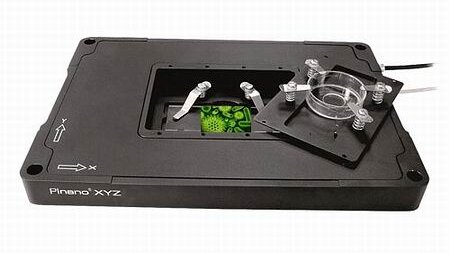

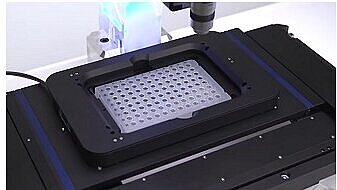

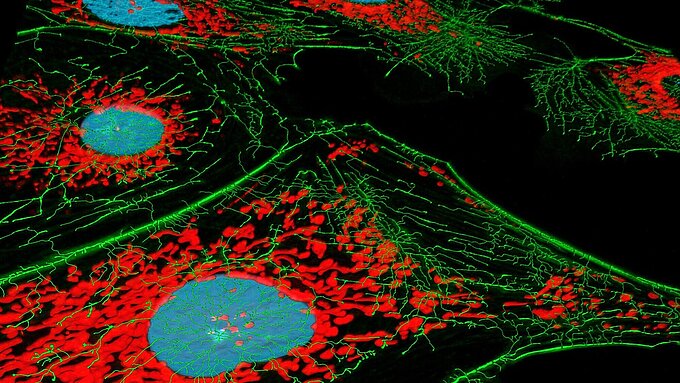

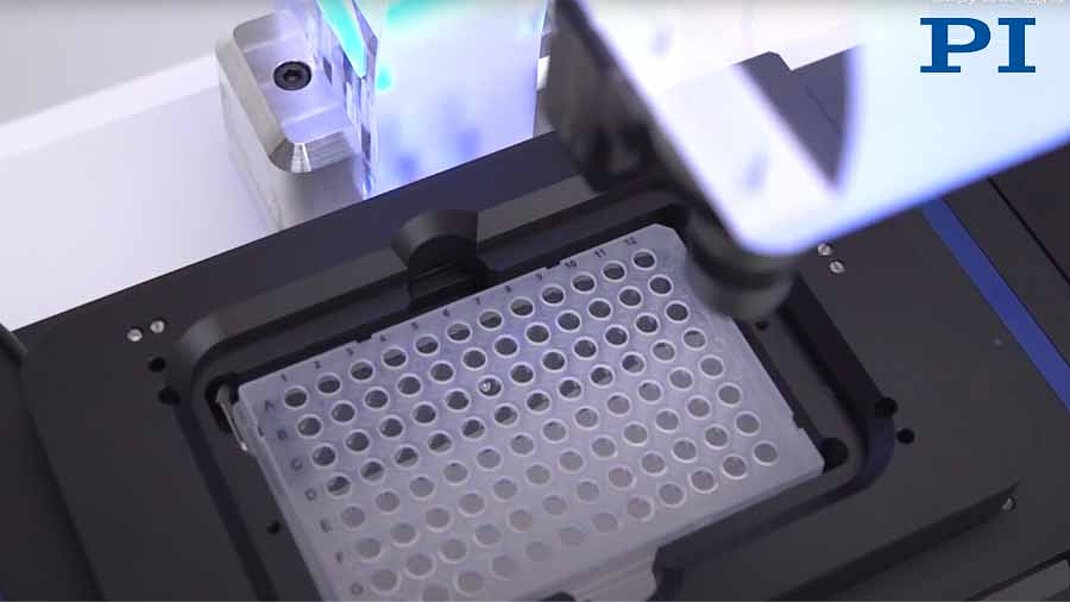

The technique pays big dividends in bio-technology and pharmaceutical applications because it now allows the complete and thorough examination of micro well plates in just seconds. Conventional motion and image analysis processes at high magnification were too slow to achieve 100-percent testing, and randomized testing was the only alternative. What works well for bio-technology is also useful in semiconductor metrology and material science applications.

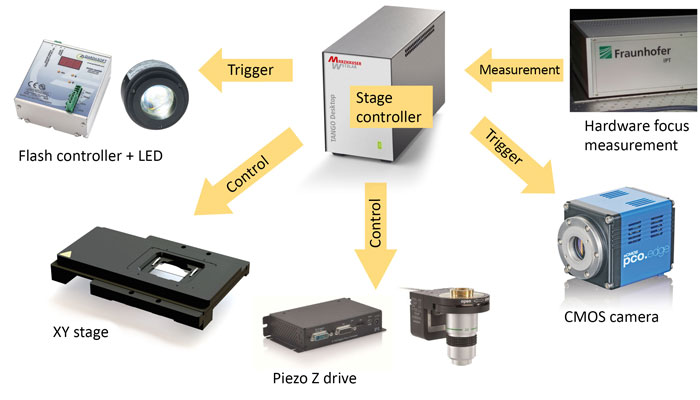

The new approach by the scientists at the IPT keeps the XY scanning stage moving the object to be tested at constant velocity during the image recording process. However, because of the relatively large variations in the surface topology (caused by precision limitations of injection-molded plastic micro well plates), a static fixed microscope objective cannot be used. The height variations would considerably exceed the depth of focus and lead to blurry, useless images.

As a countermeasure, a fast focus drive with an adjustment range of 400 µm and nanometer precision is employed. A real-time autofocus function is necessary for three-dimensional image recording; the focus must be adjusted dynamically in the direction of the optical axis with high precision. This is where the piezo-driven microscope lens scanner comes into play.

Combined with the latest software and hardware for fast data handling and image-processing this precision micro-mechanical device now allows for complex tasks, such as stitching processes, to run virtually in real-time. Individual images can be merged seamlessly into the overall image even while measuring is in progress.

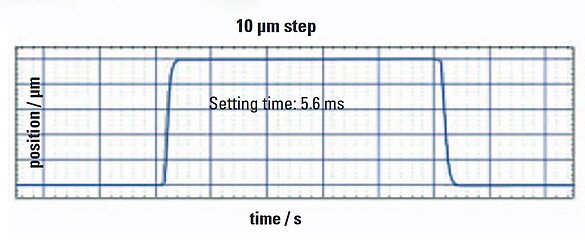

Piezo mechanic drives can respond with a position change within milliseconds of a drive voltage change with precision in the nanometer range or even below. The process is very repeatable, ensuring that the microscope object stays in focus all the time even during high scanning speeds.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy