Electron microscopy allows investigations with extremely high lateral resolution down to a range of less than one nanometer. However, this places great demands on the imaging elements. And, of course, the specimens need to be positioned with the same precision to give meaningful measured results. Drives and positioning systems therefore perform important tasks in electron microscopy.

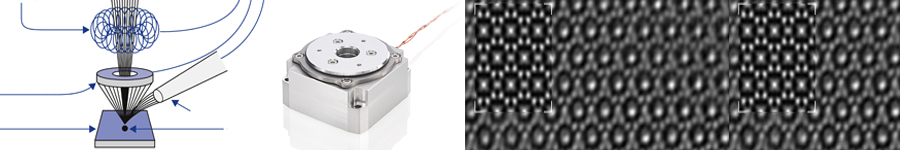

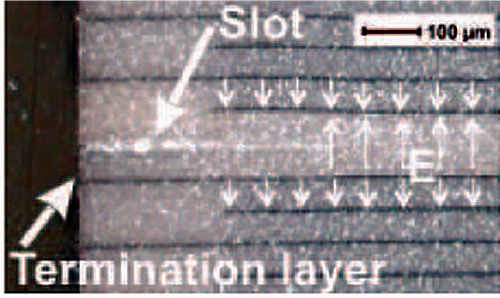

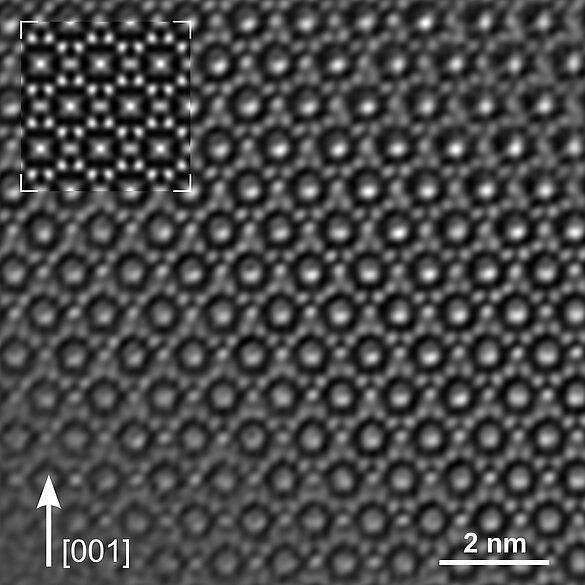

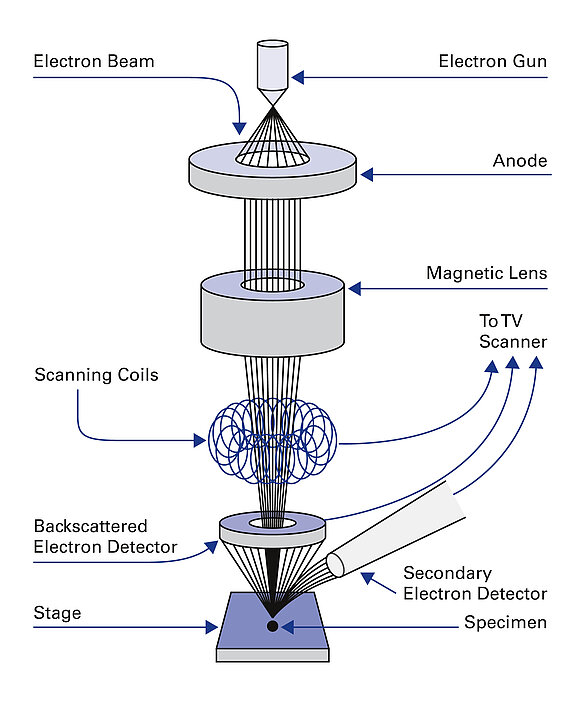

High-resolution, electron-microscopic methods (Figure 1) are employed wherever optical investigation methods no longer suffice in structural investigations and where suitable specimen preparation is possible. Due to their extremely high resolution, it is even possible to detect the distances between individual atoms. Transmission electron microscopes (TEM) achieve resolutions down to 0.1 nm, scanning electron microscopes (SEM) achieve resolutions up to a range of 1 nm, and are thus considerably better than optical methods. Confocal light microscopy generally achieves between 200 to 300 nm, optical super resolution with commercial systems achieves down to 20 nm.

Typical applications for electron microscopy are widespread today, extending well beyond research applications into industrial applications such as surface and structure inspection in semiconductor technology and materials research as well as the field of life sciences. In combination with an ion beam, even three-dimensional investigations are possible, whereby the ion beam removes individual layers of the specimen. In the case of minute structures on semiconductors, this allows determining layer thicknesses by counting the number of superimposed atom layers. In the field of life sciences the smallest cell structures are made visible. The specimens can, among other methods, be prepared with special freezing processes.

Stable Positioning and High Repeatability

And the various applications all have one thing in common: increasingly automated inspection processes require flexible and reliable drive solutions which must operate under conditions of vacuum and ideally be lubrication-free and non-magnetic. In the case of TEM, the specimen needs to be kept as stable as possible. Manipulation of specimens in the nanometer range is obligatory, after all, the viewing field is only 150 nm.

In the case of SEM (Figure 2), resolution is directly dependent on the position of the specimen. If the specimen is moved during the scan, then repeatability and the stability of the positioning stages are crucial for the quality of the images in addition to resolution. Distortion of the images can only be avoided if no drift of the specimen occurs once the target position has been reached. The positioning stages need to meet the highest requirements for smooth motion at velocities of a few nm/s. Only then, moving to exact positions on the sample surface is possible with the highest precision and without any visible jitter when the EM image is monitored directly by the user. Piezo stepping drives are particularly suitable here.

Piezo-Based Drive Solutions

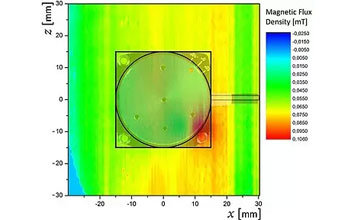

Piezo-based drive solutions can meet all the above requirements of electron microscopy and a large range of drives, actuators and multi-axis positioning systems, all of which are lubrication-free and vacuum-compatible are available. The piezo-based drive concepts developed in-house do not generate magnetic fields and are not influenced by them. This allows positioning systems to be assembled that are completely (including the guiding) or partly (except for the guiding) nonmagnetic.

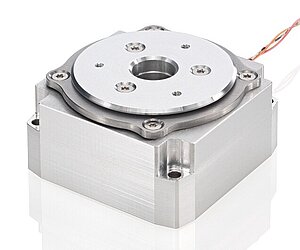

For positioning tasks, simple actuators or drives can, for example, be integrated directly at the electron beam, where they are used for correcting the beam guidance or for aligning apertures (Figure 3). Linear and rotation stages are suitable for positioning of the specimen, either for preparation prior to examination, for rapid scans or for precise alignment in the beam path. These stages can also easily be combined to multi-axis solutions. Rotary positioning of the sample is often required in sample preparation for SEM. Compact rotation stages (Figure 4) allow the specimen to be transported quickly, for example, in dual-beam installations from the electron beam path to FIB analysis and processing. The rotation stages can also be used for generating multi-axis sample scans in SEM or for adjusting the angles in crystallographic investigations (Electron Backscatter Diffraction, EBSD). Linear stages with piezo-based drives (Figure 5) are particularly suited for scanning specimens. In combination with a directly measuring high-resolution encoder, these stages allow very high-precision and repeatable positioning.

Position Stability and High Reliability

What all piezo motor technologies have in common, is stable, drift-free position hold at rest, without further power consumption. Consequently no heat is generated, which is advantageous, especially in a vacuum environment. This makes piezomotors suitable for precise and stable positioning even during long downtimes. At the same time, drives are particularly reliable because they work as direct drives without any additional mechanical transmission components, such as gearheads. This rules out mechanical restrictions such as backlash, making the drive maintenance-free.

For all systems, suitable control electronics and controllers are available which can be seamlessly integrated into existing systems thanks to their analog and digital interfaces and the extensive software support. A number of different piezo-based motor technologies are available as the requirements for drive and positioning solutions can vary considerably in the field of electron microscopy.

Matching Motor Technology to Requirement

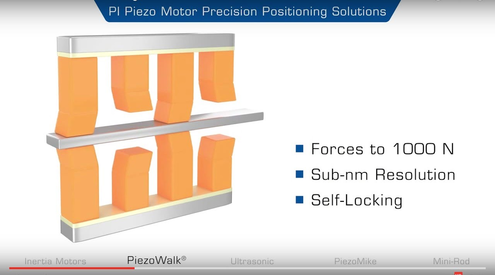

With PiezoWalk® stepping drives, piezo actuators operate in pairs as clamping and feeding elements on a moving runner (Figure 6). Cyclical control thus induces a stepping motion of the actuators on the runner, and the runner is moved forwards and backwards. PiezoWalk®stepping drives offer nanometer resolution and velocities to 10 mm/s.

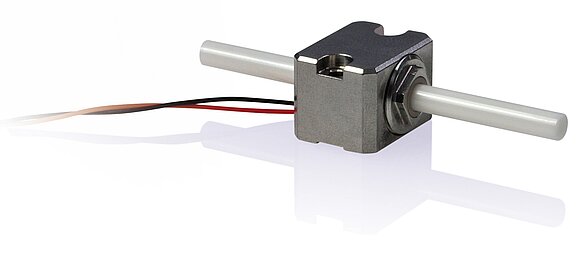

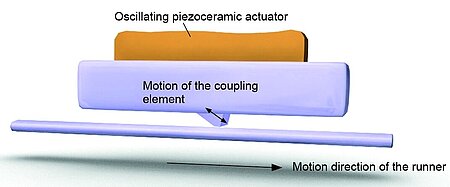

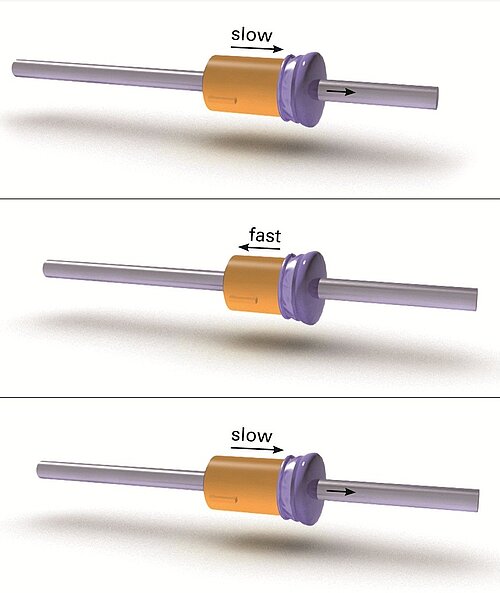

Ultrasonic piezomotors (Figure 7) are suitable for high feeding velocities and positioning tasks in the sub-micrometer range. The piezoceramic actuator is excited to ultrasonic vibrations with a high-frequency AC voltage between 100 and 200 kHz. Deformation of the actuator leads to a periodic diagonal motion of the coupling element, relative to the runner. The high frequencies ensure high velocities of several 100 mm/s. PI’s mini-rod inertia motor drives are also of interest for use in and with electron microscopes (Figure 8). They are based on a single piezo actuator and utilize the stick-slip effect (inertia effect). Here, the piezo element generates cyclic alternation between dynamic and static friction between the actuator and a moving runner. With an operating frequency of more than 20 kHz, this generates a continuous feed of the runner at velocities of more than 10 mm/s at nanometer precision levels. Due to the variety of piezo motor technologies, piezo-based drive and positioning solutions are well suited for all requirements in electron microscopy.

AUTHOR: Dipl.-Phys. Gernot Hamann, Business Development Manager for Microscopy at Physik Instrumente (PI) GmbH & Co. KG

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy