“Developing new concepts, from simulation to prototype in collaboration with our customers: This is how we drive innovation”. Motion control specialists Christopher Mock and Dr. Simon Kapelke give insights into the development process of PI's active damping and vibration compensation solutions.

Since motion and precision are key competences at PI, it's a logical consequence to integrate active vibration compensation into motion systems to achieve higher levels of precision.

Here, compactness and performance gains are key. Talking about active vibration compensation, it is obvious that the basic idea and requirements are not new. There are numerous solutions available on the market serving a variety of different applications. In terms of high precision motion control, typical solutions can look as follows: you take some type of isolating device, a frame that compensates external disturbances, and, on top, you mount your high precision positioning device - or probably a PI system.

In principle, it's always a good idea to collaborate closely with the customer to get a common understanding of the application’s requirements and the solutions we can deliver.

In most cases, this is an iterative process, including for example adaptation of concepts, model refinement or parameter identification. Once we understand the customer’s requirements, we start to build up models and a virtual system to simulate and study the situation. We iterate until the customer is confident that the solution is the best we can achieve.

When you want to achieve nanometer precision, the absence of external disturbances is critical. In real-world applications without vibration control, there are limits that the best nanopositioning systems cannot exceed. Our innovation is the ability to combine motion and active vibration control into one system, enhancing precision to new levels. In this case, we have invented a process to optimize the modal decoupling of the customer’s mechanics. After implementing this technology and seeing for the first time the difference between switching it on and off - the result was groundbreaking.

So, a big team effort was rewarded with a very good solution. This way of collaboration - developing new concepts with customers, running simulations, building first prototypes, and finally bringing ideas to life - is how PI drives innovation.

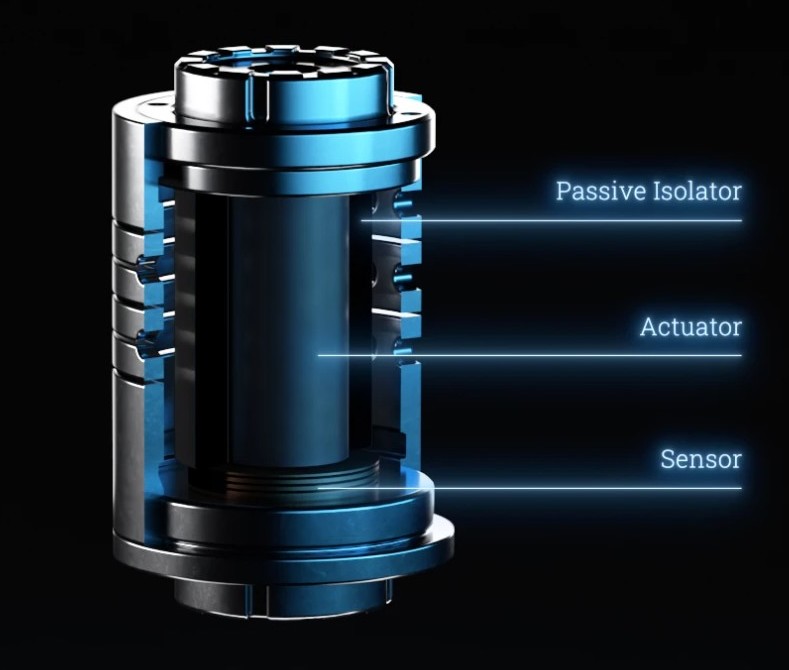

Integrated Motion and Active Vibration Compensation in Brief

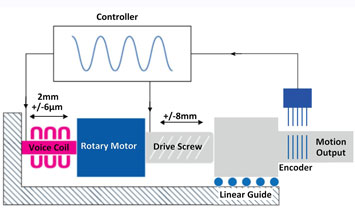

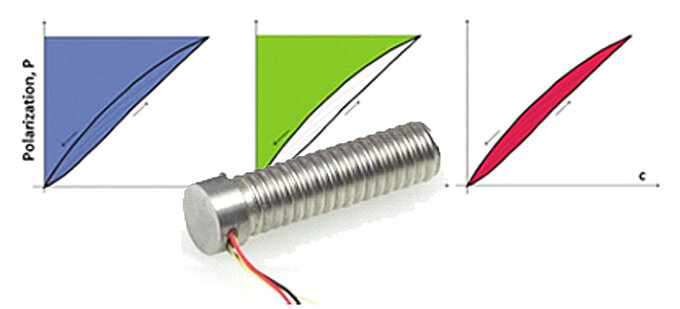

Smart Fusion of Technologies: High-precision actuator and sensor technology is combined with advanced control strategies for active damping and compensation of vibrations.

Dealing with Eigenmode Frequencies: Mechanical structures are amplifying disturbances at eigenmode frequencies due to forces acting on the frame on which the motion device is mounted.

Damping of External Disturbances: To ensure stability and mitigate unfavorable impacts, external disturbances originating from the environment, such as the floor, machine frame, or suspension, are actively dampened.

Suppression of Internal Vibrations: Disturbances caused by the motion of the components located on the tabletop will be actively suppressed.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy