Different Scanning Stage Concepts for Precise Motion Control in Optical Coherence Tomography (OCT) Applications

OCT is an interferometric imaging technique based on broad band infrared light, typically ranging from 0.8µm to 1.4µm to optimize tissue penetration. OCT has long been used in ophthalmology but recently also finds growing application in dermatology, for example to fight skin cancer. In comparison to conventional invasive diagnostic measures, OCT delivers results faster and reduces side-effects and stress on patients.

Precision Motion Systems for Scanning

Since the OCT technique relies on the axial scanning of an optical beam in one of the interferometer arms, highly precise nanopositioning stages are required to provide maximum imaging resolution.

Several drive concepts can be used for to satisfy the requirements of modern OCT systems.

- Piezoelectric Flexure-Guided Nanopositioning Scanners

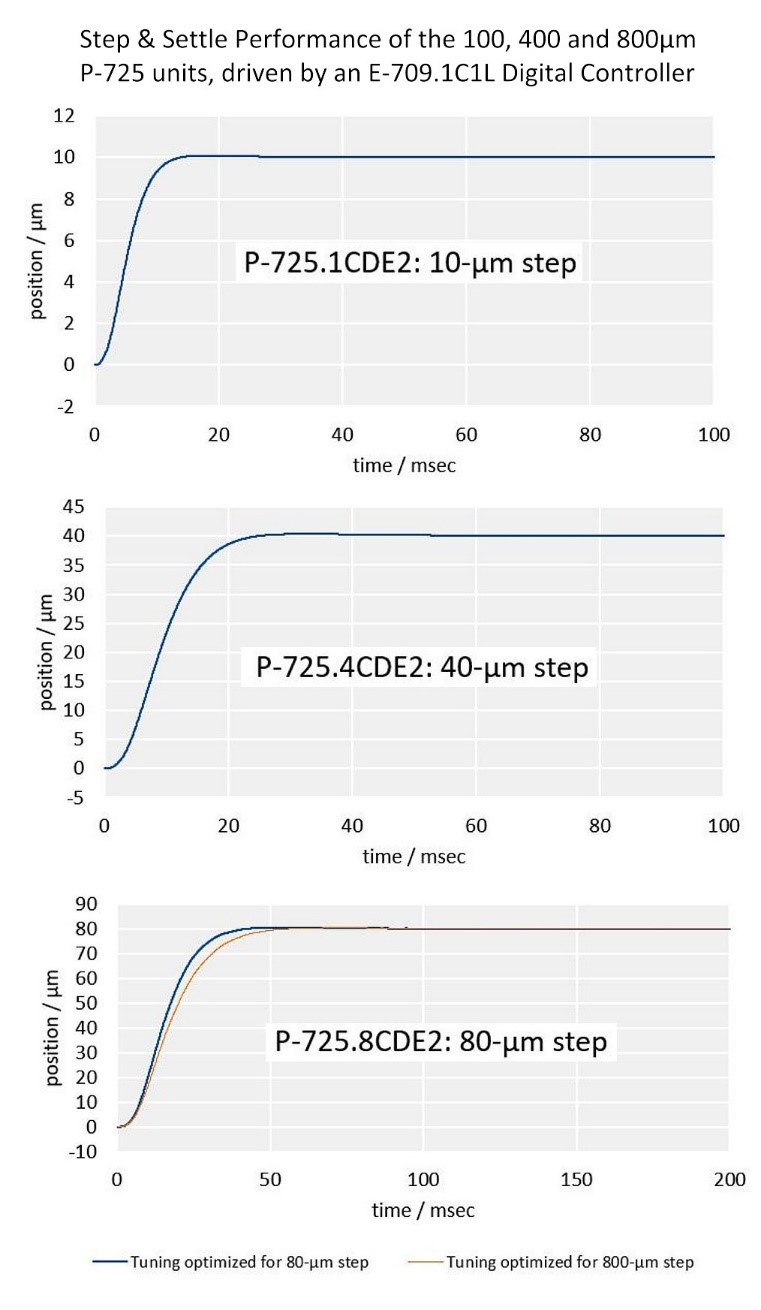

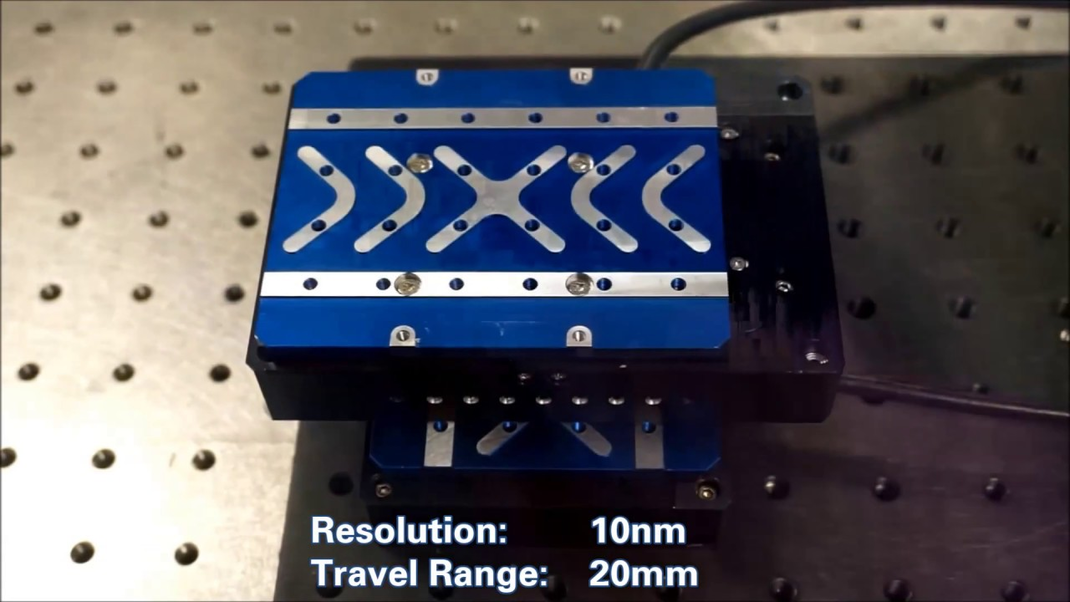

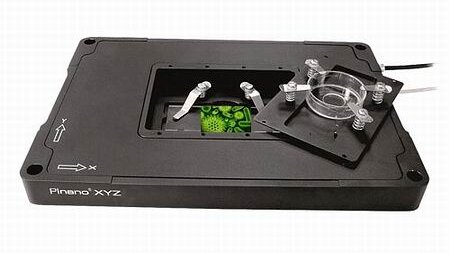

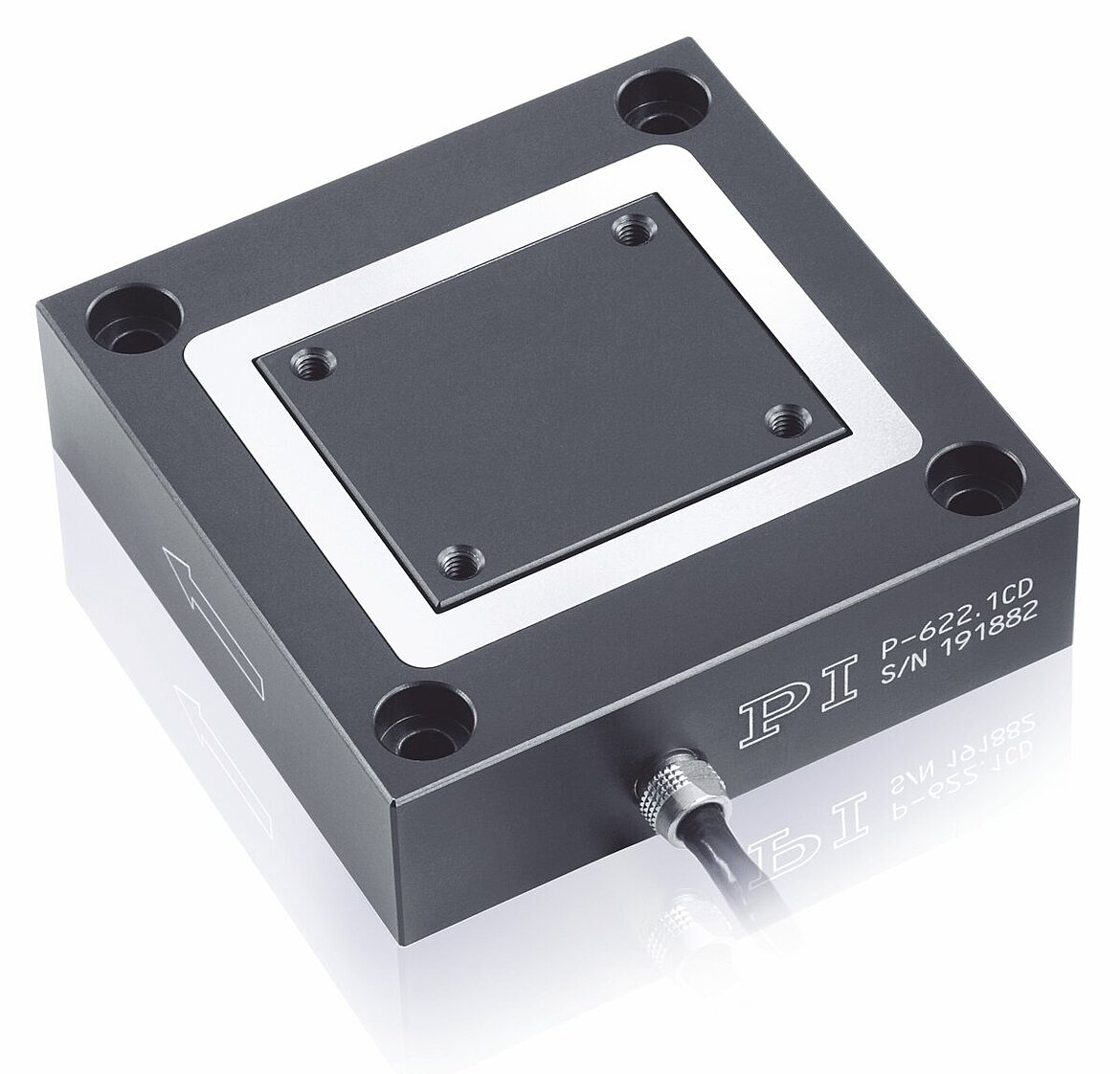

Several piezo-driven motion principles are feasible. The two examples shown below are based on piezoelectric stack actuators driving a flexure-guided stage platform and a microscope objective mount, respectively. Flexure-guided, piezoelectric linear nanopositioning stages provide the highest possible resolution and precision; in addition, they are both friction-free and wear-free and virtually require no power to hold a position.

- Voice Coil Linear Motor-Driven Scanning Stages

Voice coil motors are based on the electromagnetic principle well-known from loudspeakers. They are best suited to motion ranges from ~0.5mm to 25mm (1 inch). Voice-coil motors are frictionless, wear-free, and can provide highly dynamic and precise motion, as every music lover can attest to. When used in scanning and positioning stages, they are often combined with crossed-roller rails to provide high precision guidance. Linear encoders integral to the scanning stages provide feedback to a closed-loop motion controller to allow for precise position and velocity control.

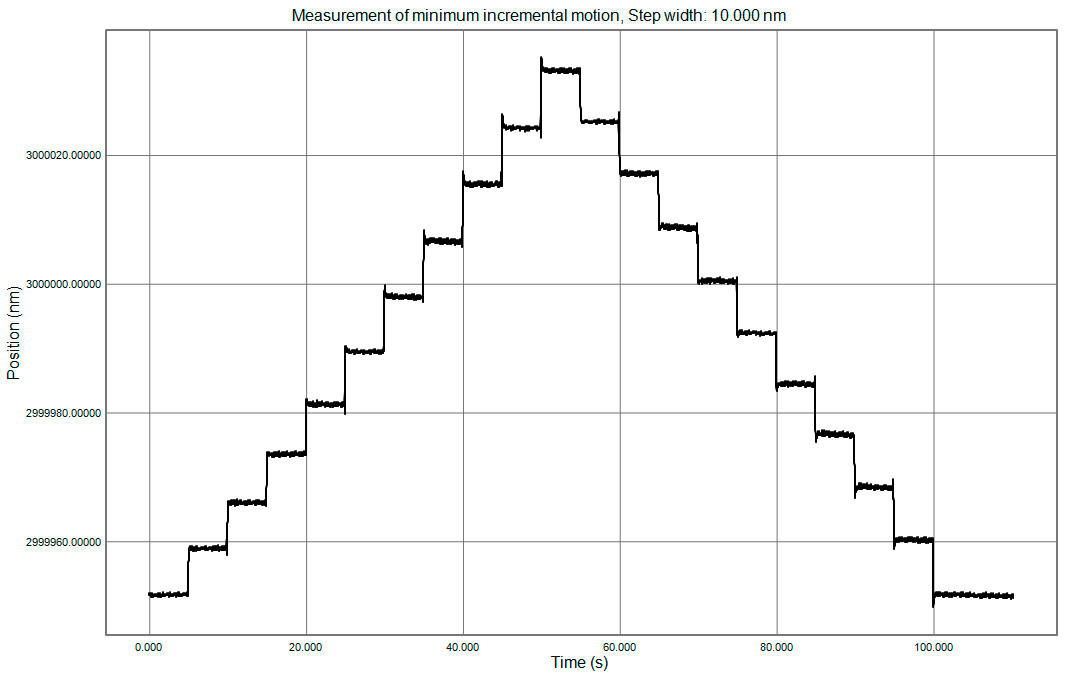

The graphs below show the settling performance of different piezo driven objective scanners (right) and nanometer precise steps of a voice-coil motor driven scanning stage.

- Piezo-Motor Driven Scanning and Positioning Stages

Piezoelectric motion/ positioning stages, based on the ultrasonic-drive principle, are also available. These provide travel ranges typically 10 to 150 millimeters and can be designed to fit in small spaces.

OEM Motion Solutions for OCT

If you have an application in interferometry, OCT, microscopy or surface metrology, email or talk to a PI engineer to discuss your OEM requirements for standard or custom stages and special OEM controllers.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy