Intelligent Motion Control: How Active Alignment Technology Speeds Up Manufacturing of Optical Systems

Over the span of forty years, the field of precision positioning and motion control has vaulted forward in broadly beneficial ways. For example, submicron-resolution linear encoders, once available only in the costliest stages, are now affordably integrated into mechanisms as large as gantries and as small as matchbook-sized nanopositioners. New motor concepts abound, ranging from the familiar DC servo, stepper and linear motors to include novel technologies like high-speed, ultra-stable resonant piezomotors and diminutive stick-slip stages with nanoscale positionability over many millimeters of travel.

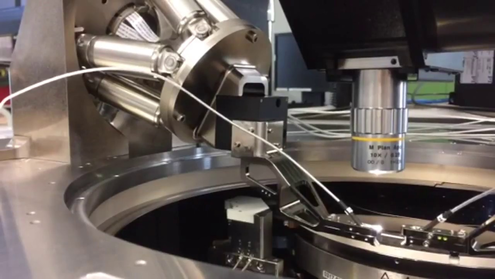

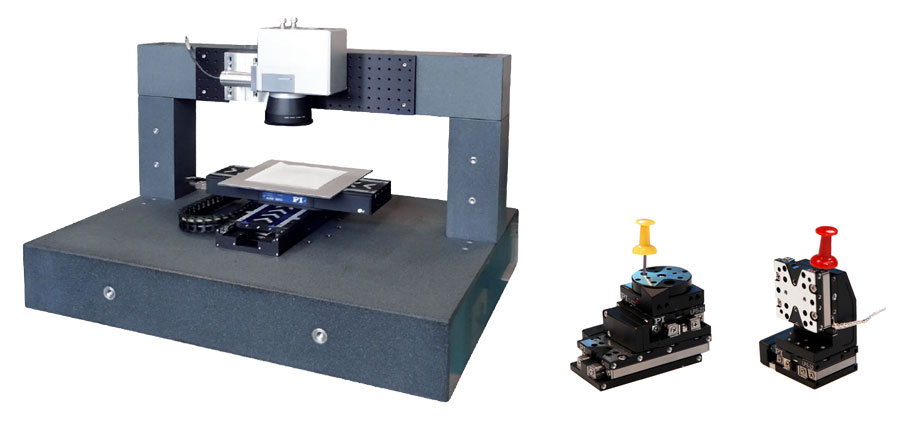

Meanwhile applications as complex as Silicon Photonics packaging automation, micro-optical assembly tooling and nano-robotics all benefit from new combinability of axes and mechanisms of various types. Controls technologies have broadened and specialized but have also adopted extensible interfacing architectures, including both proprietary buses and open approaches like EtherCAT. These provide highly distributed capability where each axis and functionality is optimized for its task, resulting in an assembly with no compromises.

Positioning: Until now, a study in obedience

But as advanced as today’s precision positioning mechanisms and controls have become, they still basically do what they are told. A position is commanded, and achieved. A sequence of motions is specified, interleaved with metrology and other processes, and proceeds according to script. In that strictly operational sense there is little difference from the positioning systems of 1985. Instead, the advancements have come in resolution, speed, compactness and similar physical attributes, and in controller attributes like scriptability, data recording and other features.

Take a high-altitude view, however, and there is another trend beginning to manifest— and one with profound significance for applications. Review the broad tectonics of the positioning field, and it is clear that positioning is suddenly becoming more intelligent as well. Already, specialized systems have become available that not only achieve commanded positions and motion patterns with alacrity but can also determine, on their own, the optimal position and orientation needed for their application.

Intelligent motion systems replace simple positioning systems

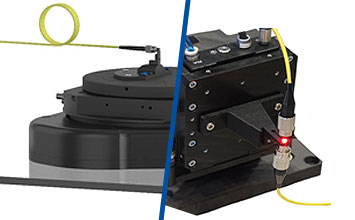

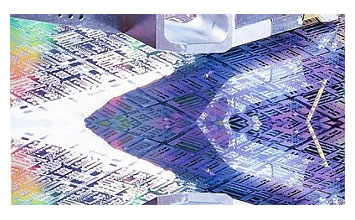

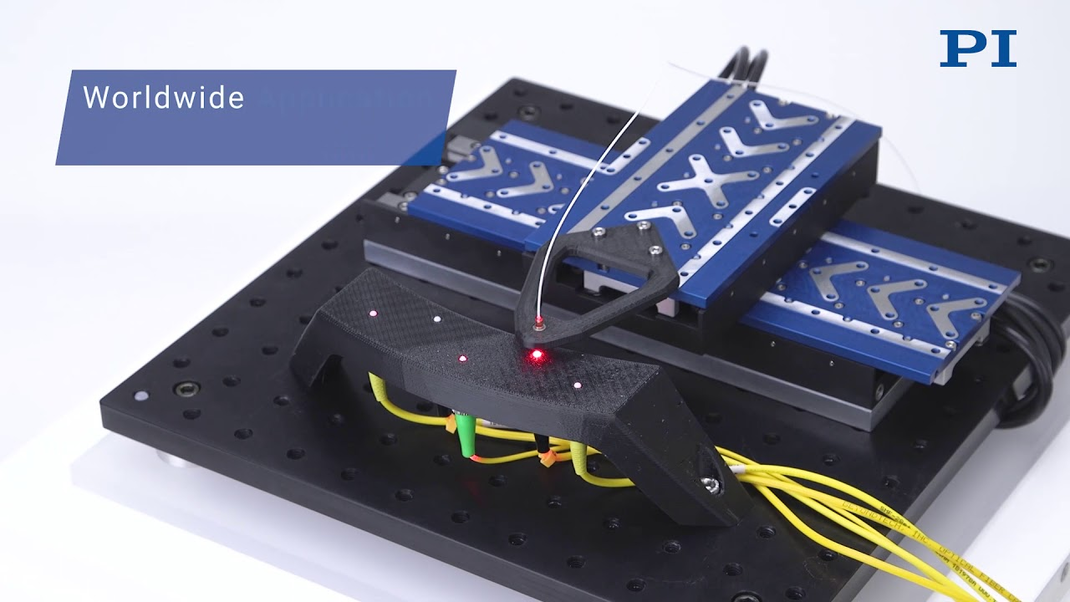

This trend started in the field of photonics process automation. Even in the dawn of the fiber optic field in the late 1980s, there was a need to automatically align elements for test and packaging, accommodating device-to-device variations and fixturing uncertainties that could not be machined-out or detected with even the best machine vision. This optimization was achieved by software. In those early days, computers were used to sequence precise but dumb positioners along with optical-power metrology in ways that could eventually determine and achieve the optimal mutual orientation of photonic elements like the then-novel single-mode fibers and laser diodes. The optimization sequence could be as simple as a brute-force raster-scan of an area of interest to determine the position of a peak, or starting in the early 1990s a digital gradient search could be performed to climb the coupling profile efficiently and even provide tracking of thermal drift and curing stresses.

But the intelligence remained in the computer. The algorithms that performed the optimization resided in the software, and the throughput of the system was crimped by the ability of every positioning axis and metrology subsystem to respond to the computer’s moment-by-moment commands. At the same time the sophistication of the software’s real-time capabilities was limited by the slowness of all the elements being orchestrated. Yet until recently this has remained the state of the art.

A new class of truly intelligent positioning

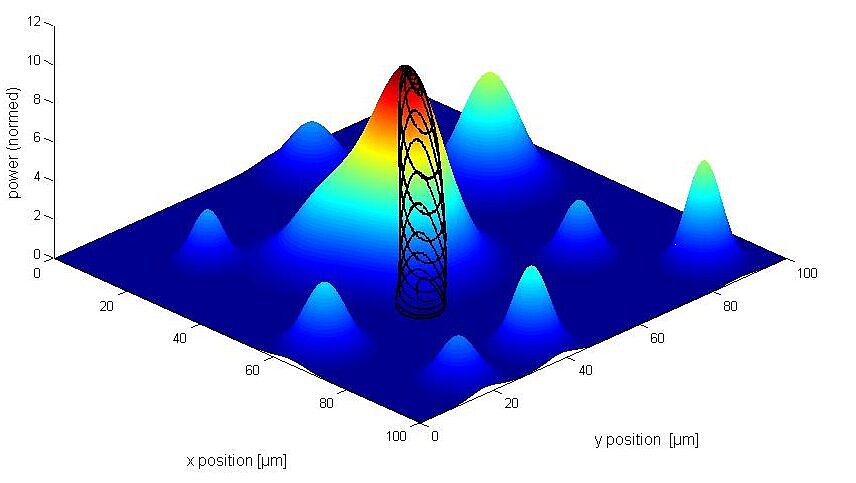

Over time, more and more sophisticated optimization algorithms were developed, for example to allow simultaneous optimization of multiple photonic elements across multiple channels and degrees of freedom. These algorithms use micron- or even nanometer-scale exploratory motions to measure the local gradient of a figure-of-merit such as optical power, and then the systems automatically follow that gradient to the point at which it falls to zero: the peak, the optimum, the desired position and orientation of the elements. This is a definitive and unique condition familiar to students of the Euler-Lagrange equation and—as it turns out—a condition universal to optimization challenges.

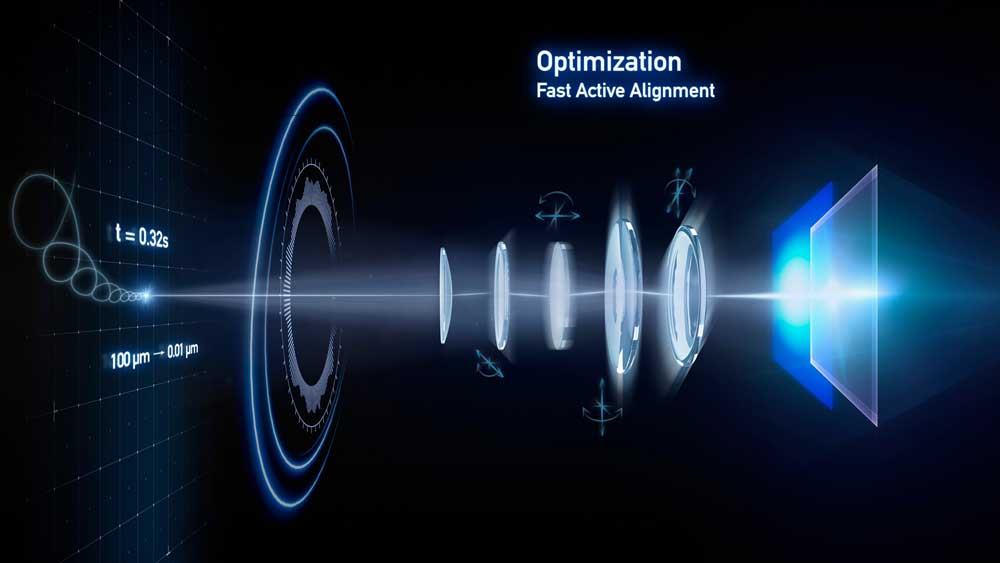

In a groundbreaking advancement, these newly intelligent algorithms have recently deployed in the firmware of specialized controllers whose compute power handily exceeds that of the Cray supercomputers of those early days of photonics. Combined with multi-axis positioners of exquisite precision, these provide micro-robotic functionality that reduces the time required to assemble photonic devices… and not by a small amount; process-time reductions of 99% or more are common. This has proven to be an economic enabler for the industry, and the systems have enjoyed considerable commercial success and not a few awards.

The target: Broadly reducing manufacturing costs

But remember that high-altitude view. It turns out that this new class of intelligent positioning is suitable for many applications outside Silicon Photonics. After all, many industrial deployments of ultra-precision motion control are aimed at peaking up some quantity or another as devices are assembled. The manufacturing of lasers is a good example: the output power of the laser must be optimized. Camera manufacturing is another: in that field, image quality is the metric to be maximized. And so on.

Examples such as these abound. All involve a figure-of-merit which reaches a peak at the desired position and orientation. And similar bounties of process-cost reduction are seen when conventional micro positioning is supplanted by these new intelligent optimization engines combined with high quality industrial multi-axis positioning mechanisms. Furthermore, the pioneering parallelism that benefited Silicon Photonics production economics so dramatically—the ability to simultaneously align multiple photonic elements across multiple channels and through multiple degrees of freedom in one step—also applies broadly to the general case of industrial precision assembly.

Enabling intelligence by enabling parallelism

The key is how the parallel optimization can replace time-consuming loops. For example, a gimbaling optimization of a lens in theta-X and theta-Y formerly needed to periodically halt so that the transverse alignment in XY could be corrected, and then the theta-X/theta-Y optimization could start over again, and on and on in a lengthy loop until a global consensus optimum is achieved. Now, both optimizations can proceed simultaneously, yielding substantially faster global optimization and greatly reducing process costs.

We see now that this is broadly applicable to many manufacturing fields. All that is needed is for the optimization controller to directly receive an adequately fast figure-of-merit, and the optimization can then begin across all the involved channels and degrees-of-freedom. In familiar Silicon Photonics applications, the quantity being optimized is optical throughput, meaning power. So the signal conveyed to the controller is typically the output of a high-bandwidth optical power meter or transimpedance amplifier. That is all the controller needs to intelligently determine the optimal position and orientations of the elements it is positioning.

Returning to the new applications examples cited above, it’s easy to see how this capability maps to these new applications. In the case of a laser cavity, the mutual orientation of reflectors, gratings and other constituents similarly must be optimized, and the figure of merit is optical output. Dependencies between elements and geometrical dependencies for each element can be unwrapped automatically through the parallelized algorithm. In the case of a multi-element camera such as the billions of increasingly sophisticated smartphone cameras assembled each year, the metric of image quality can be a straightforward and fast calculation of image sharpness, such as a 2D FFT or modulation transfer function calculation. When conveyed to the controller at a high rate, this can similarly drive the simultaneous optimization of elements across multiple degrees of freedom, reducing or eliminating the need for those time-consuming process loops.

Optimization is universal

Key to all this is the fact that most figures-of-merit are substantially unimodal peaking functions near optimum, meaning they exhibit a hill-shaped profile that rises and then falls as the orientation of each element is exercised in each of its degrees of freedom. The same internalized mathematical algorithms that achieved the radical capability of simultaneous optimization in Silicon Photonics production applies in these additional applications as well. At the root of this capability is the novel, parallelized digital gradient search, a specialized category of gradient ascent algorithm that itself is a relative of the Euler-Lagrange equation. This is a highly generalized technology, hence its broad applicability. Importantly, a model of the coupling and dependencies need not be known, nor must the application be predictable or tightly reproducible.

Enabling a precipitous decline in production cost

What this means for production economics across these new fields is still unfolding, but the promise is similar to what we have seen in Silicon Photonics process automation. Fields as diverse as LIDAR, lasers, life sciences, data storage, quantum computing—virtually any field where production economics are impacted by lengthy process loops in pursuit of a global consensus optimization—will benefit.

Which brings us back to that high-altitude view. We witness a foundational shift in positioning technology, from its advancing history of positioners ever more precisely doing what they told, to do to a new paradigm of truly intelligent positioning. The era dawns where positioners can now perform autonomous optimization of process quantities, and the consequences for industry will be broad and deep.

Author: Scott Jordan

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy