Motivation

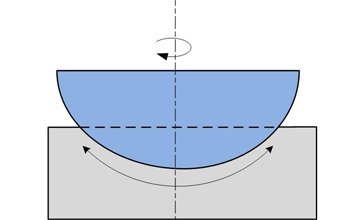

In this post, we present terminology related to the test and metrology of highly accurate rotary stages (spindles) commonly used in the precision motion industry. The aim is to help customers and users from different industries speak the same “language” as our engineers.

Introduction of Terms and Concepts

Below are the terms that are used to define the performance of a spindle. The often requested “repeatability of eccentricity” spec by customers is equivalent to AEM (Asynchronous Error Motion) in the language of our metrology engineers.

ACE | Centering Error of the Artifact |

AEM | Asynchronous Error Motion |

AIE | Inherent Error from the Imperfection of the Artifact |

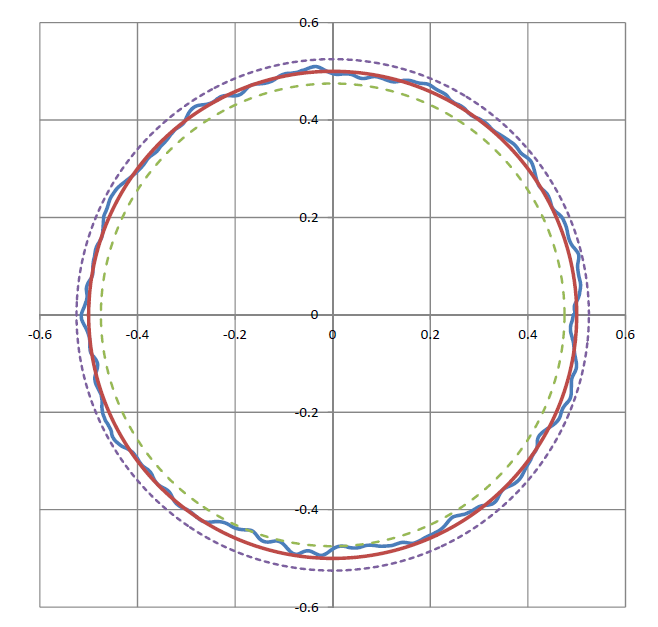

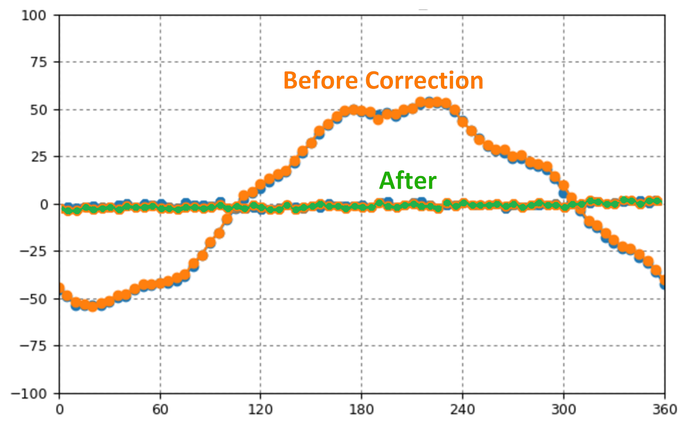

NRRO | Non-Repeatable Run Out It’s the non-repeatable portion of the error motion and it is also called as Asynchronous Error Motion (AEM). In the customer’s terms, this is the repeatability of the eccentricity. The NRRO also contains the noise of the measurement devices and the test setup, so very careful data processing is required to derive the true error motion coming from the spindle. For this reason, the AEM data of any spindle is not published yet. NRRO (AEM) = TIR – RRO NRRO = NRRO (spindle) + Measurement Noise |

RRO | Repeatable Run Out On top of the true spindle error, there are also errors coming from the test setup including the centering error of the artifact (ACE) and the inherent error from the imperfection of the artifact (AIE). The ACE component needs to be taken out during post processing of the data. The AIE can be also taken out during the post processing using rather sophisticated algorithms (such as the Donaldson Reversal Method) but the error is relatively small (often less than 25 nm) and can be ignored. Please note that ACE and the AIE are not the common terms but are used to express in a simple equation as below. RRO = SEM + ACE (+ AIE) |

SEM | Synchronous Error Motion The SEM is the repeatable error coming directly from the performance of the spindle and it can be derived by taking the ACE component out of the RRO. SEM = RRO – ACE (+ AIE) |

TIR | Total Indicated Reading This is the raw data taken with any measurement device. TIR can be categorized as a repeatable portion (RRO) and a non-repeatable portion (NRRO) of the motion error. TIR = RRO + NRRO |

Example of Test Results

The asynchronous error motion (AEM) is derived by taking the average error motion out of the Synchronous Error Motion (SEM) plot (Green Line minus Blue Line, Orange Line minus Blue Line). This is the Non-Repeatable Run Out (NRRO) of the spindle and, as stated above, it also contains the measurement noise coming from the test setup and the devices used, which could contribute significantly in an uncontrolled test environment.

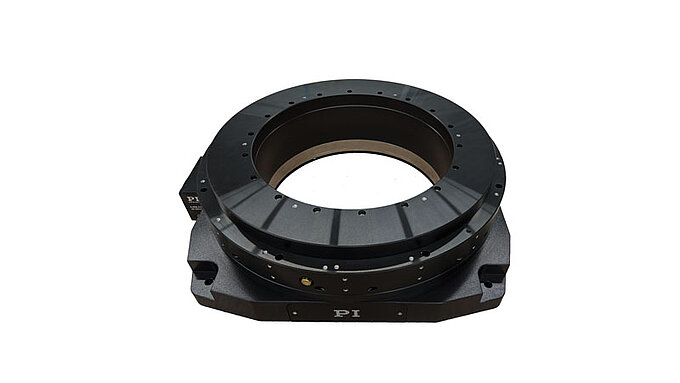

In general, the performance of a rotary stage depends on the bearing type and diameter. Larger diameter stages provide better performance than smaller units, air bearings provide better precision than mechanical bearings. A high performance controller can also improve performance by smoothing out torque ripples of the motor.

Conclusion

To address customer questions regarding the repeatability of eccentricity, it is essential to provide contextual information about rotary stage tests. By doing so, we can gain a deeper understanding of the value associated with eccentricity and the various factors that contribute to it. It is important to note that there are both controllable aspects related to design and assembly, as well as inherent environmental factors that influence the overall error.

Note: For those interested in the actual ANSI/ASME Standard, please refer to ASME B89-3-4 2010. Rev2019. Axes of Rotation: Methods for Specifying and Testing

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy