“Building this modular platform from scratch was essential for the products we want to develop in the future.” Dr. Julien Mintenbeck, our Head of Platform Development Electronics, gives insights into the genesis and current state of PI's modular control platform.

We see new technologies and features such as big data, digitalization or new connectivity options and we see that more and more PI products must be integrated into a heterogeneous landscape with other third-party devices.

In the beginning, we looked at our PI controller portfolio to find all important features we already offer, and on the market side, we looked at the requirements that are needed to build up a concept for the software as well as the hardware architecture to allow integration of PI solutions at a completely new level of technology.

In parallel to the development process on our side, we collaborate continuously with external partners, research institutes, and test customers to get fast feedback during our complete development process.

Future-Proof Modular Platform

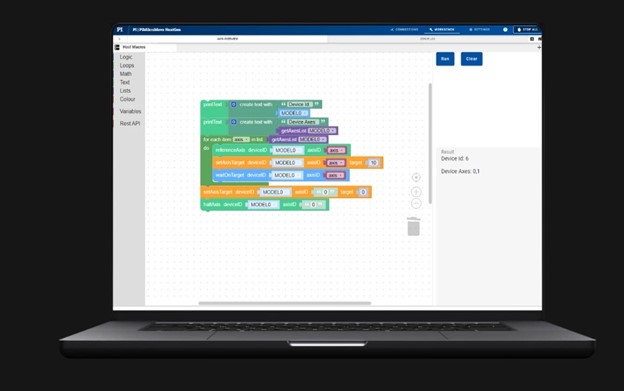

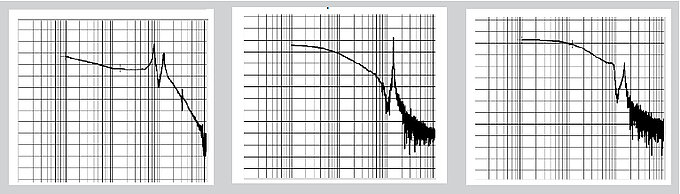

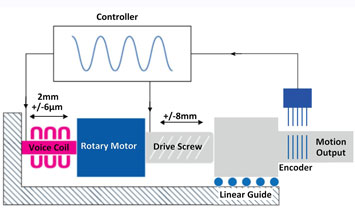

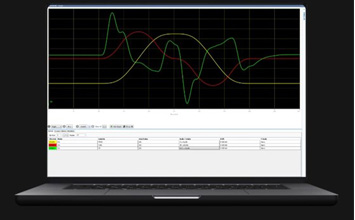

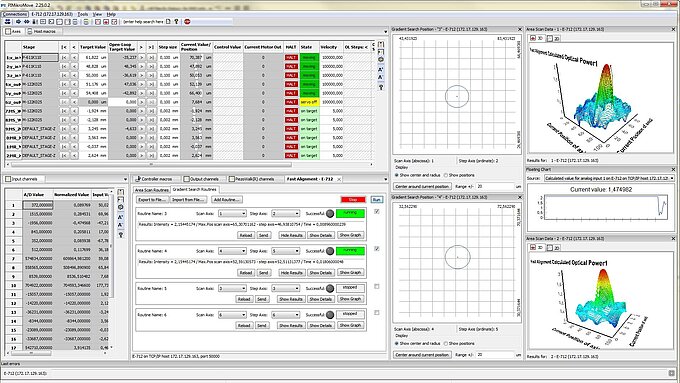

We are designing a completely new modular platform that will satisfy the requirements for the future products and systems we are going to develop in the next five to ten years. The core features and unique features of such a technology are the central platform architecture to handle hybrid systems, piezoelectric and magnetic drive systems. We have up to 16 axes that can handle 100 kilohertz servo cycle, that's cutting-edge technology now, and we have a completely new web-based software ecosystem with no and low code programming options that you can use for PI products as well as for ACS controllers.

For the end customer, there's a significant benefit on the use of such a platform because we enable the user on the application side to build their own application with their own programming capability – starting from a model and converting it into a productive system later on.

You can use the same hard and software from the beginning of your application until the end. With this project, we have very powerful technology and bring that complex technology to the end customer in an intuitive and user-friendly way.

Modular Control Platform in Brief

Modular Architecture: The open and modular controller architecture facilitates seamless integration of different drive and sensor technologies, software solutions, and communication standards.

High-Speed Data Transmission: The operation of 16 axes with high-speed data transmission of 100kHz bandwidth will make high-performance process control possible.

Customizable to Individual Needs: The versatile modular platform will empower the creation of hardware solutions meeting specific application requirements – from standalone control for single-axis drives to high-performance multi-axis control.

Fast Start-up and Easy Programming: The web-based development environment offers the possibility of fast and easy start-up and the implementation of individual applications without in-depth programming knowledge.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy