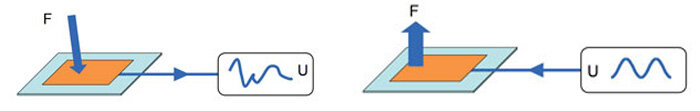

Piezoelectric transducers can turn vibration into electric energy (“the direct piezo effect”) and electric energy into motion (“the inverse piezoelectric effect”). They are used in everyday applications from buzzers to gas igniters and in high-tech markets from medical to semiconductor applications. Typical piezo elements are made of PZT ceramics and the piezoelectric effect responsible for their function is based on frictionless solid state effects. It works extremely fast and direct – no need for gears and traditional power transmission elements.

Windows, tiles or furniture can become loudspeakers

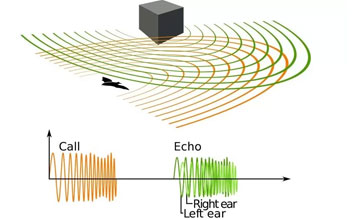

A relatively new and exciting field for piezo applications is vibration acoustics: Imagine turning walls, windows or furniture into speakers or hands-free microphones that control your home electronics – or minimizing road noise in your car.

The Italian start-up company HST srl holds a patent on using piezo elements as both sensors and actuators in alarm systems and provides sound-rendering solutions that turn window panes into loudspeaker membranes. Sound rendering also works with other structures, such as furniture, ceiling surfaces and tiles – allowing underwater sonification in swimming pools.

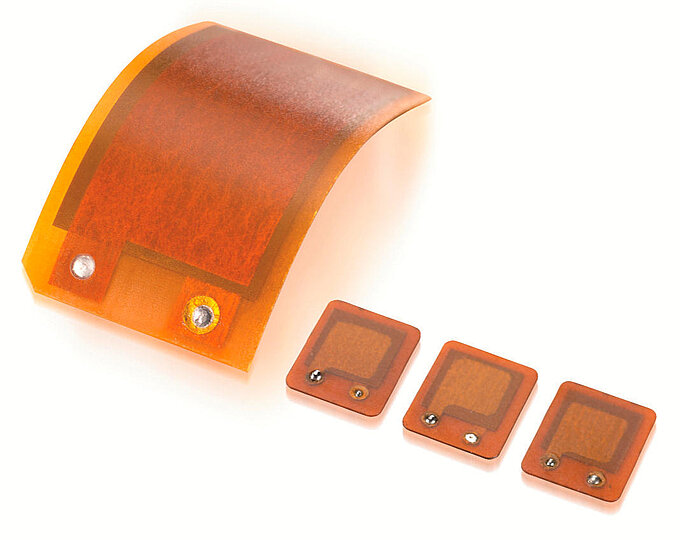

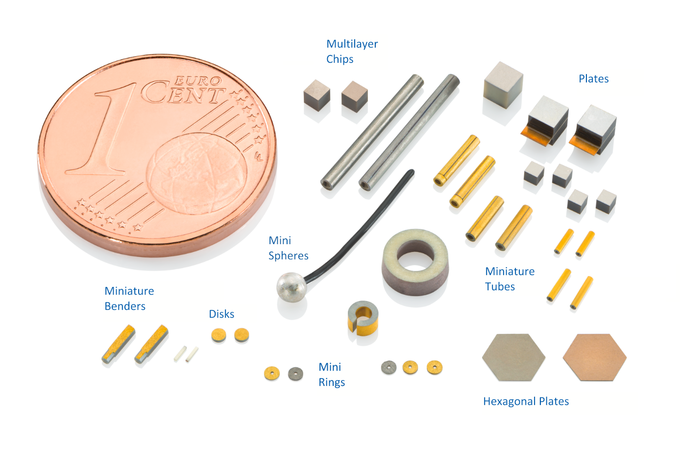

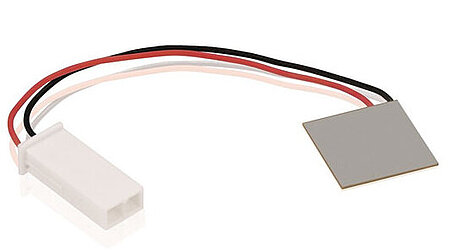

Miniature Piezo Transducers – Easy to Integrate

HST has teamed up with German piezo specialist PI Ceramic (PIC) on several successful projects and uses PIC piezo transducers exclusively for its piezo acoustic systems. The piezo elements used are very compact, only 20x20mm and 0.5mm thick, essentially the size of a postage stamp.

New Surround Sound Experience, Thanks to Piezo Technology

The more structures equipped with piezo elements, the more intensive the sound experience. For background music in a typical living room, an average of one piezo element per 4m² of living space is sufficient. If speech is to be reproduced, an average of two elements per 1m² should be used. For taller rooms or sound systems in conference rooms that require more acoustic performance, two to three elements per 1m² surface area are recommended. Using the direct piezo effect, these elements can replace traditional microphones used in conferencing systems when integrated in tabletops or lampshades.

Powerful Controller for Many Functions

Installing a piezo-based sound system is simple – the transducers are bonded to the structure elements and plugged into an electrical control system providing power for up to 30 elements. The piezo controller connects to cell phones, tablets or a music system via Bluetooth or a phone jack.

The user friendly software provides several innovative options, such as following the occupant from room to room, by reading sensors integrated into the door sill. The same can be used to turn on lights on and off automatically.

Protects James Bond from Eavesdropping and Ordinary People against Burglary

The piezo elements can also be used to sense manipulation of a window, feeding the acoustic signal into an alarm system while the piezo elements installed inside the room can scare off the perpetrator with a shrieking sound. Software that evaluates the vibration spectrum of the windows prevents false alarms by recognizing rattling, wind buffeting etc.

If programmed accordingly, the piezo elements in windows can also be used to actively cancel out street noise and if you are a double–zero agent, you’ll appreciate the anti-eavesdropping option, keeping your secrets from the hands of the enemy.

About HST

HST srl is an Italian start-up company founded by Ph.D. researchers trained at Politecnico di Milano, now at the head of Soluzioni Ingegneria s.r.l, and local industrialists. It concentrates on structural vibration acoustics, where receptors are built into existing architectural structures, such as doors, windows or furniture. Passive structures are then transformed into active systems for sound generation as well as sound and vibration recording, for speech recognition systems, prediction of seismic events, and for active noise cancellation. HST obtained an international patent in 2012 and presented its market products for the first time in 2013.

About PI Ceramic (PIC)

PI Ceramic, a member of the PI Group, is a global leading supplier in high-end piezo ceramic transducers and assemblies for standard and OEM piezoelectric device solutions. The wide range of in-house piezo materials available at PIC and the great manufacturing flexibility allows fast adaptation to the customer’s requirements. PI Ceramic’s material research, design, and manufacturing engineers provide standard and custom transducers for all important high-tech markets, including industrial automation, semiconductor manufacturing, medical engineering, precision machining, automotive engineering, and aeronautics.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy