When selecting a motion controller / driver for a piezo nanopositioning system, a number of questions need to be answered first. Here’s a check list and an example that can help make the best choice. You can also just contact a PI engineer for support.

Before getting started, information needs to be gathered on how the system is going to be used and what performance is expected.

These can be broken down into drive signal related information and mechanical information.

Required Drive Signal Information

- Maximum required stroke / amplitude

- Signal type (sinusoidal, triangular, trapezoidal, steps, …)

- Frequency / duty cycle of the drive signal

- Rise / fall time of steps

- Operation time (Continuous 24/7, a few minutes or seconds at a time, …)

Required Mechanical Information

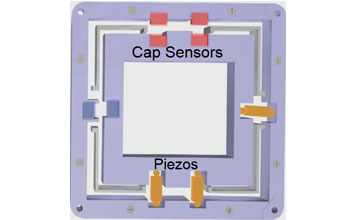

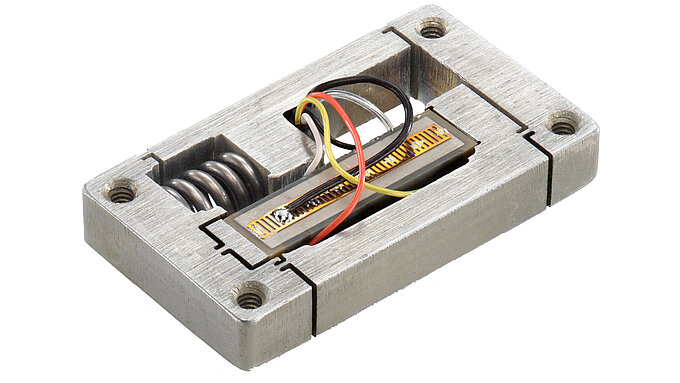

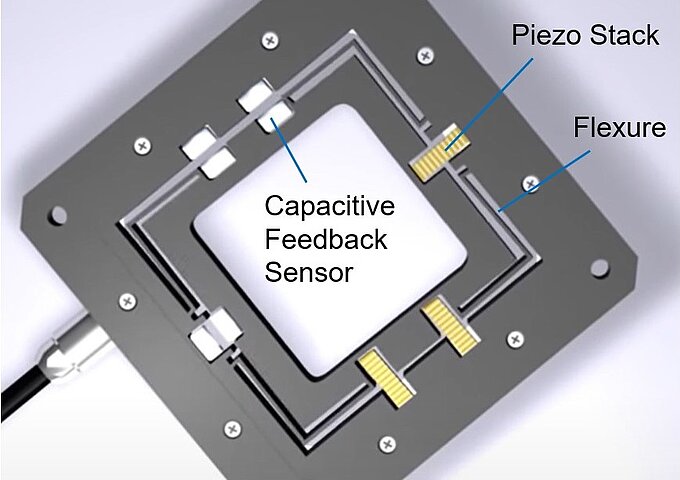

- Number of axes, travel range, stiffness, resolution, external forces (preload)

- Dynamic requirements: step & settle time, operating frequency (ensure it can be met by mechanical system)

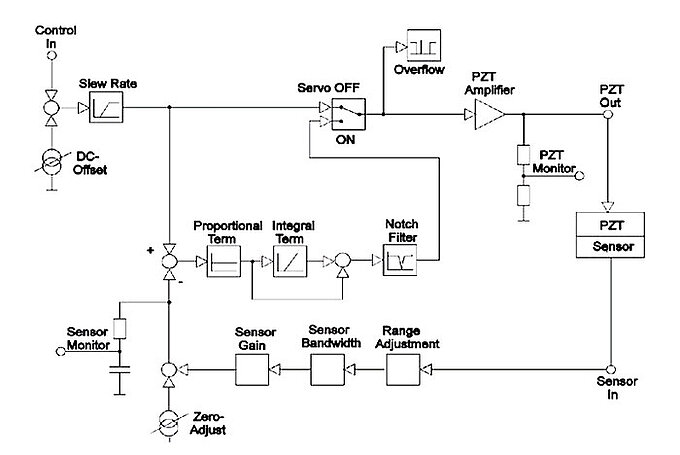

- Closed / open loop operation, sensor technology

- ID-chip option (automatically retrieve the servo parameters from the stage, all digital controllers)

- Thermal requirements: heat generation (in case of continuous high frequency operation)

Once that information is available, follow the steps in our example below.

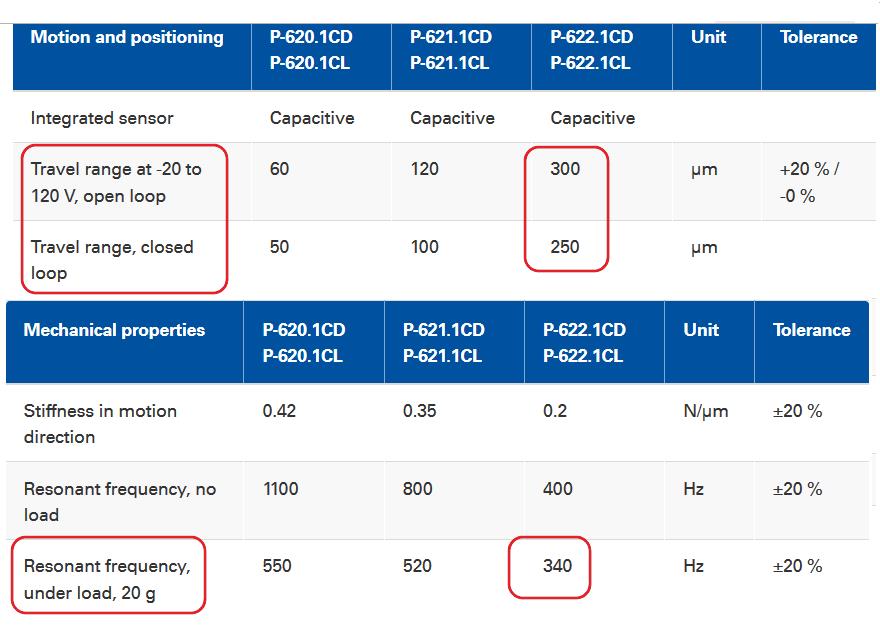

The travel range is sufficient. As a rule of thumb, about 30% of the resonant frequency is available as closed loop operating bandwidth, in our example, 1/3 of 340Hz loaded resonance frequency is close enough to the required 100Hz operating bandwidth. If this number is too low, a stage with a higher resonant frequency has to be selected.

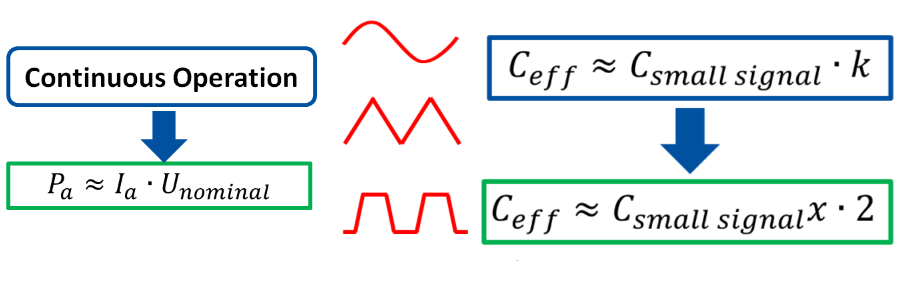

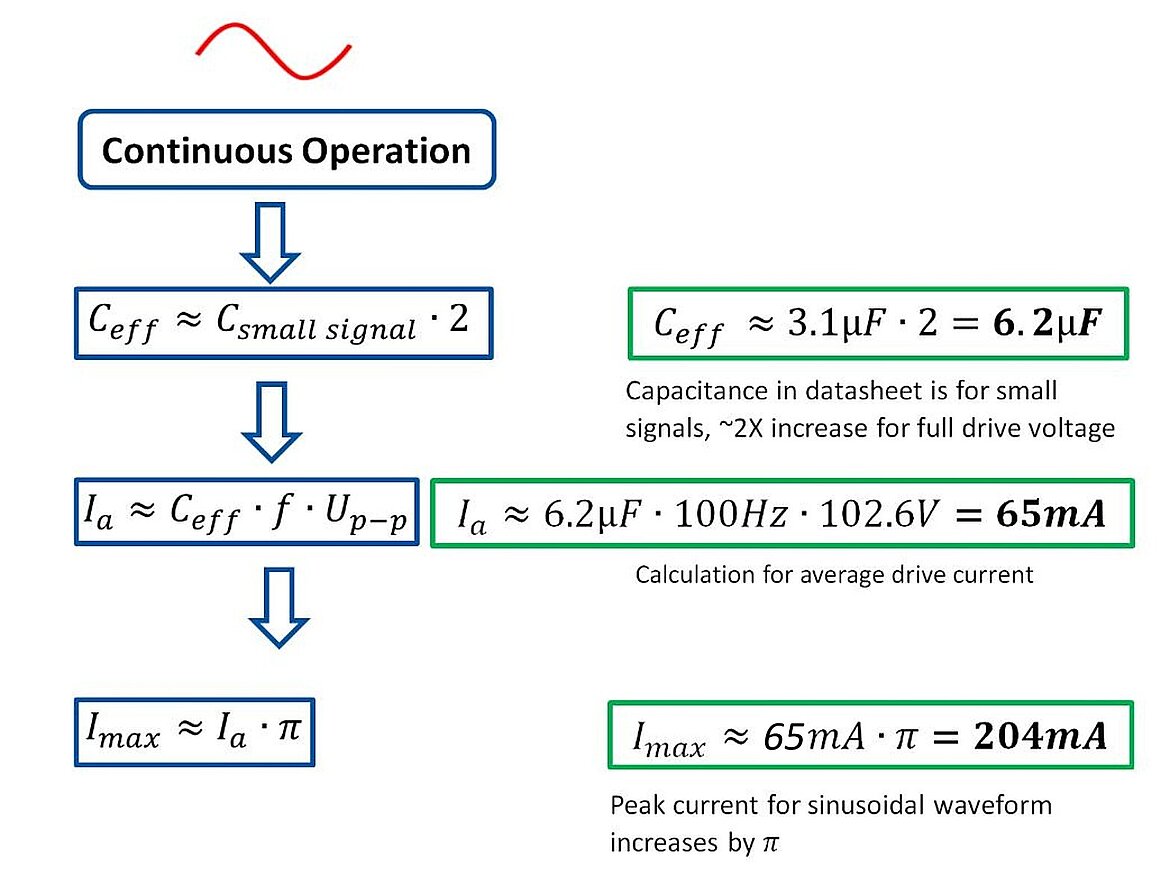

The average output current needs to be supplied by the piezo amplifier during continuous operation.

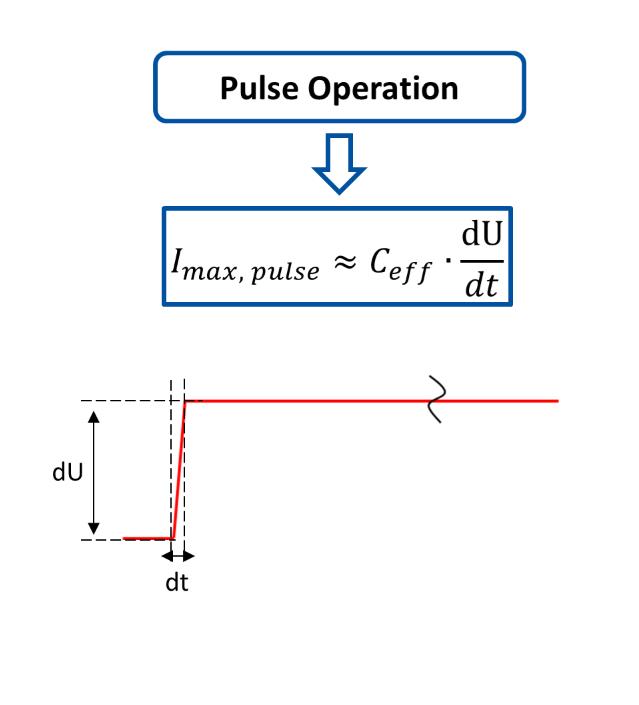

For short periods of time, a higher current can be required (e.g. maximum slope of sinusoidal signal).

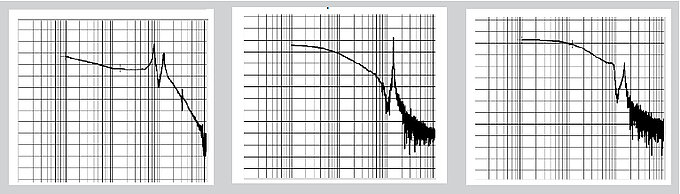

This is approximated by multiplying the average output current by a correction factor which depends on the drive signal type (see graphics).

If the calculated peak current is not well below the specified peak current of the amplifier, the expected amplitude at a given frequency cannot be reached in continuous operation, even if the average output current is in spec (the target signal would be distorted, e.g. sinusoidal would appear triangular).

The higher the required peak current, the longer it takes for the amplifier to recover.

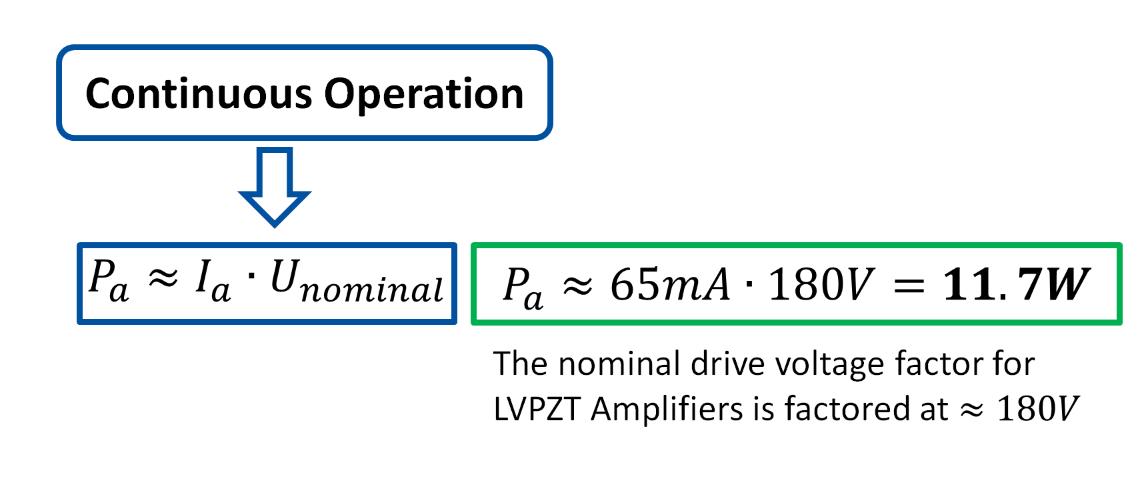

In our example, we calculated the required average drive current as 65mA.

Multiplied by the nominal drive voltage of the amplifier, the required power results, in this example, 11.7W.

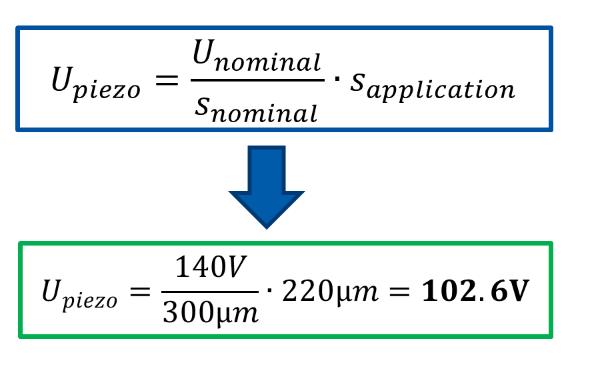

The nominal voltage for an amplifier is derived from the maximum output amplitude plus a small safety margin - in the case of LVPZT Amplifiers, we use 180V.

Pick from the recommended controllers in the datasheet and check which one provides the required current and power: If closed loop is required, pick a closed-loop controller. Digital controllers usually provide better performance than analog controllers. Take a look at the resolution, too. Higher DAC resolution leads to a lower noise and better positioning resolution as well.

Get the operating limits for the respective amplifier from the datasheet.

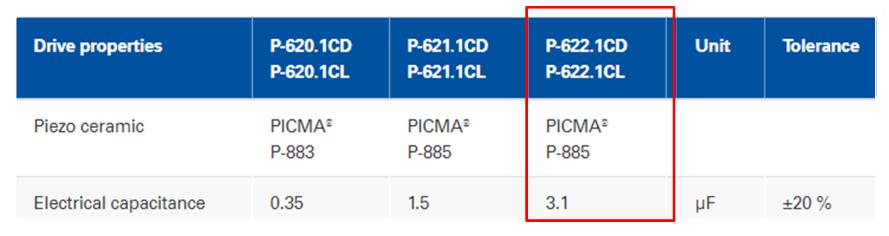

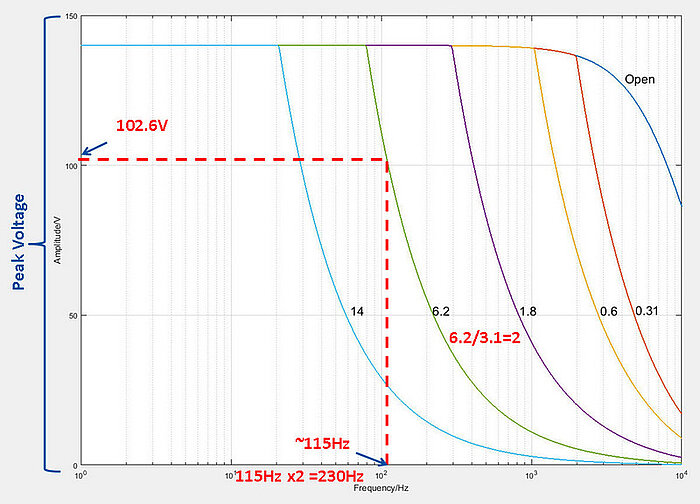

Check the maximum achievable operating frequency for the required peak drive voltage (required to achieve the desired stroke). If the exact capacitance of the respective piezo mechanics (in our example 3.1µF) is not shown, do this: Use the next larger one and multiply the result with the ratio.

In our example, the 6.2µF graph is shown (which is 2X the piezo stage capacitance of 3.1µF).

For 6.2µF at 102.6V, the frequency axis shows ~115Hz; multiplied by 2, 230Hz results, which is significantly above the required 100Hz.

Additional factors (temperature, environment, etc.) may be important, too. Feel free to check with a PI engineer for help.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy