Intensive care is an increasingly important area of hospital patient care, especially in global medical crises like the current COVID-19 pandemic. Viruses and other infections particularly affect people with pre-existing conditions such as renal or cardiovascular diseases. In regard to the treatment and therapy of such illnesses, the demands on the medical devices used are ever increasing as well. Piezo technology offers various possibilities to improve them: Using piezo transducers, for example, makes intensive care devices such as infusion systems smarter and facilitates vital patient monitoring.

Infusion Systems Using Ultrasonic Sensors

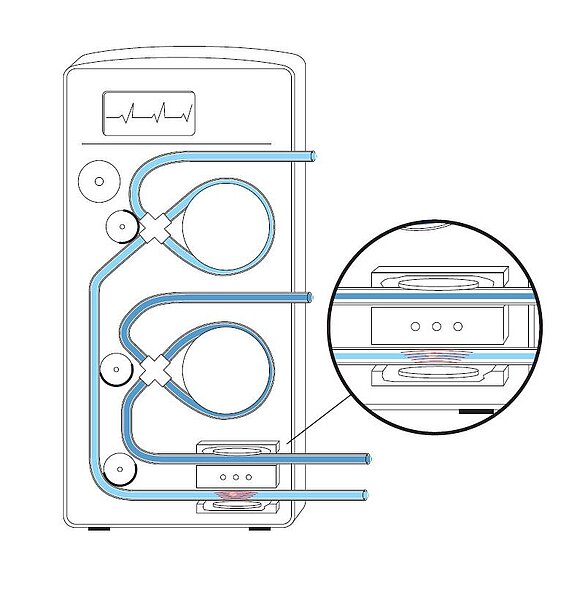

Infusion devices are widely used in intensive care medicine, e.g. in haemodialysis machines for the treatment of chronic renal diseases. These systems clean the patient’s blood in an extracorporeal cycle in a dialyzer. Diffusion occurs between the blood and a dialysis fluid, which are separated by a biocompatible dialysis membrane. This process removes toxins from the blood that would otherwise remain in the bloodstream due to the kidney damage and the consequently impaired detoxification function. After dialysis, the blood is returned into the patient's circulatory system.

In other use cases, infusion systems are applied for blood transfusion or so-called cardiopulmonary bypass which we know as heart-lung machines. During life-saving surgery, e.g. on the open heart, these systems take over the pumping function of the heart and ensure the blood oxygenation that would otherwise be executed by the lungs.

Runtime Measurement with Piezo Components

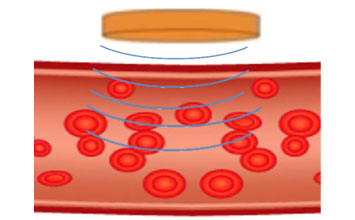

>> Piezo components integrated in an ultrasonic sensor can work simultaneously as transmitter and receiver of ultrasonic waves. The solid state piezoelectric conversion means that there is no friction or wear in the components, which makes maintenance unnecessary. When a voltage is applied to a piezoceramic disc, it operates as an actuator with a dynamic movement and generates ultrasonic waves (inverse piezoelectric effect). Using the direct piezoelectric effect, the piezoceramic is able to detect sound waves and convert them into electrical signals. When positioned in a sound path oblique to the direction of flow, piezo components measure the sound propagation time in and against the direction of flow. The flow velocity can be determined from the difference in the sound pulse propagation time.

Infusion systems and other medical devices increasingly rely on ultrasonic sensors for measuring the blood flow or detecting lethal air bubbles. This is what piezo components are particularly well suited for – the greatest advantage of these ultrasonic sensors is that they are very compact in size and can be attached from the outside of the tube as a clamp-on sensor. As this process is non-invasive and non-intrusive, contamination of the monitored fluids by the metering system is prevented.

The integrated piezo plates or discs can measure the flow of liquids in a wide variety of tubes, independent of viscosity, density or colour of the fluid or tube. These sensors are also able to detect air bubbles injected into the bloodstream in real time, enabling medical staff to detect them early on and prevent life-threatening air embolisms. Another strong case for piezo-driven metering systems: due to large-scale production, piezo sensors are very cost-effective.

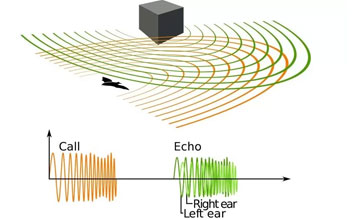

Air bubble detection significantly increases patients’ safety. Infusion systems can contain several air bubble detectors for improved monitoring. They make use of the runtime measurement of the induced sound waves. If sound waves in a tube hit an air bubble, they are reflected at the interface of the bubble, since there is a difference in impedance between the two media. In comparison to the runtime measurement in a tube without bubbles, an air bubble can be detected immediately due to the shortened runtime of the sound waves. If an air bubble is detected in the tube of e.g. a heart-lung machine, the pumping process of the infusion system is interrupted immediately. The blood contaminated with air bubbles is then diverted into a reservoir so that the extracorporeal blood circulation can once again function without interruption.

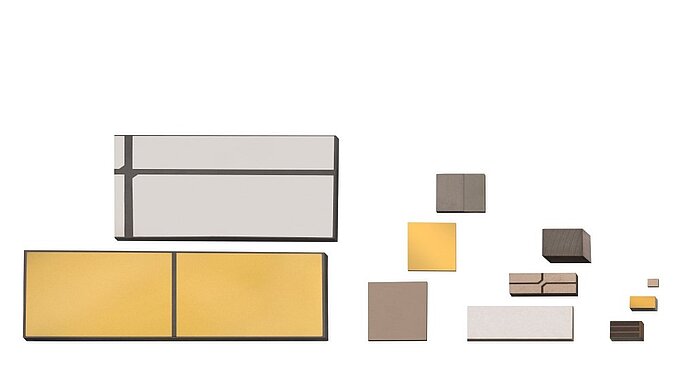

More Than Just Piezo Ceramics: Assembling Technology by PI Ceramic

In addition to various geometries, electrode configurations and flexible production quantities, we also offer to take over further processing steps from you. Whether it is integrating piezos into ultrasonic transducers or gluing piezos to membranes, PI Ceramic can do more for you than just manufacturing piezo elements. With our profound know-how in testing and packaging combined with our clean room environment, we support customers in >> gluing or contacting piezo components, as well as in assembling even entire transducers. Ask our experts!

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy