What is the Difference between a Piezo Actuator and a Programmable Piezo Shim?

New Tools for Design Engineers of Optics and Precision Mechanical Systems

Piezo stack actuators have been used in applications such as photonics alignment, positioning, force generation, and fast valve actuation for several decades. They provide high dynamics, but can also be used for quasi-static applications due to their high-stiffness and stability.

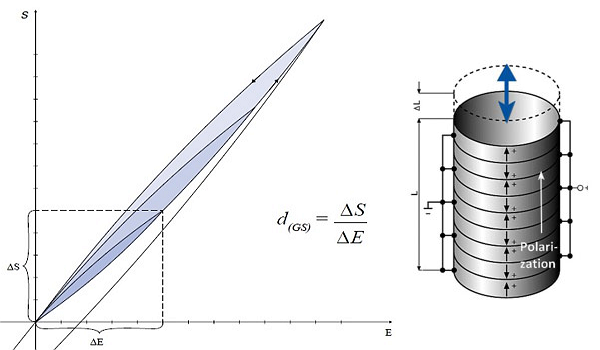

The principle is relatively simple: the extension of the stack changes roughly proportional to the drive voltage, with typical strain on the order of 0.1% of the stack’s length available. Charging and discharging of a piezo actuator is related to charging and discharging an electric capacitor.

Quasi-Static Applications

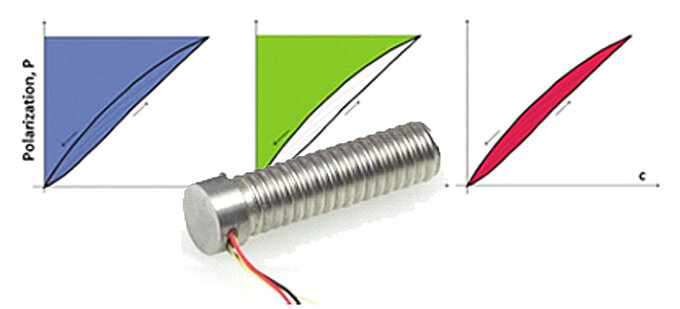

When static applications are concerned, i.e. several parts are to be aligned and held in place, piezo actuators work well, and their atomic-level resolution is welcome in many optics, laser and semiconductor related applications. However, each actuator will require a driver to maintain the required position. When the voltage source is removed, the piezo stack will slowly discharge and whatever dimensional change was affected by charging it will disappear.

Programmable Shims

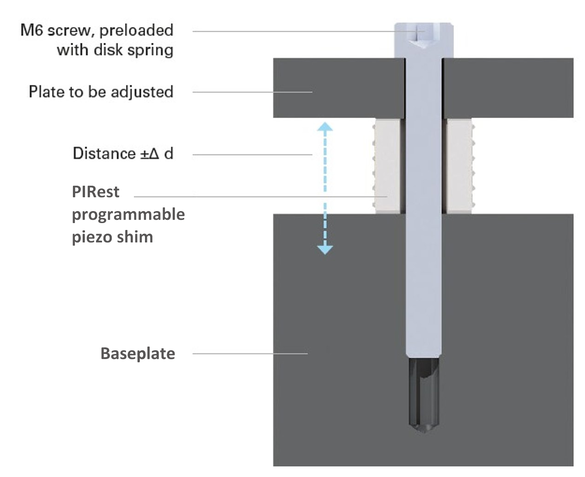

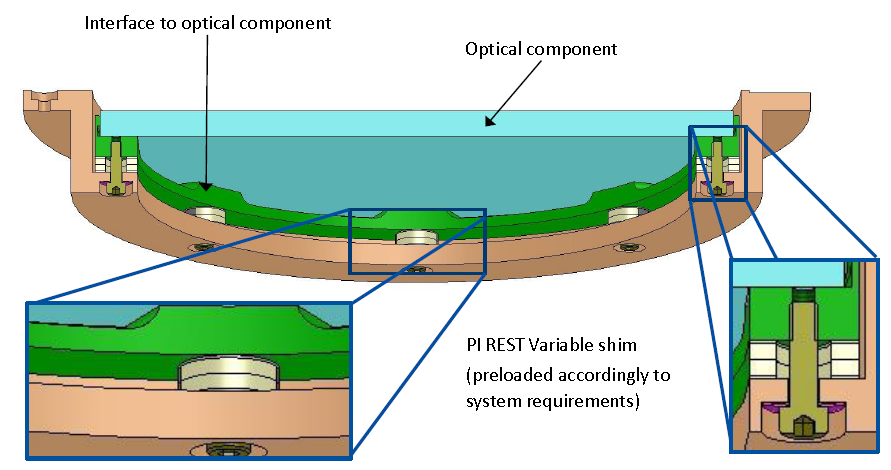

A new technology, also based on the piezo effect, can be utilized in situations where high resolution and stability are crucial, but a continuous drive voltage is unwanted and accessibility for manual adjustment is not possible.

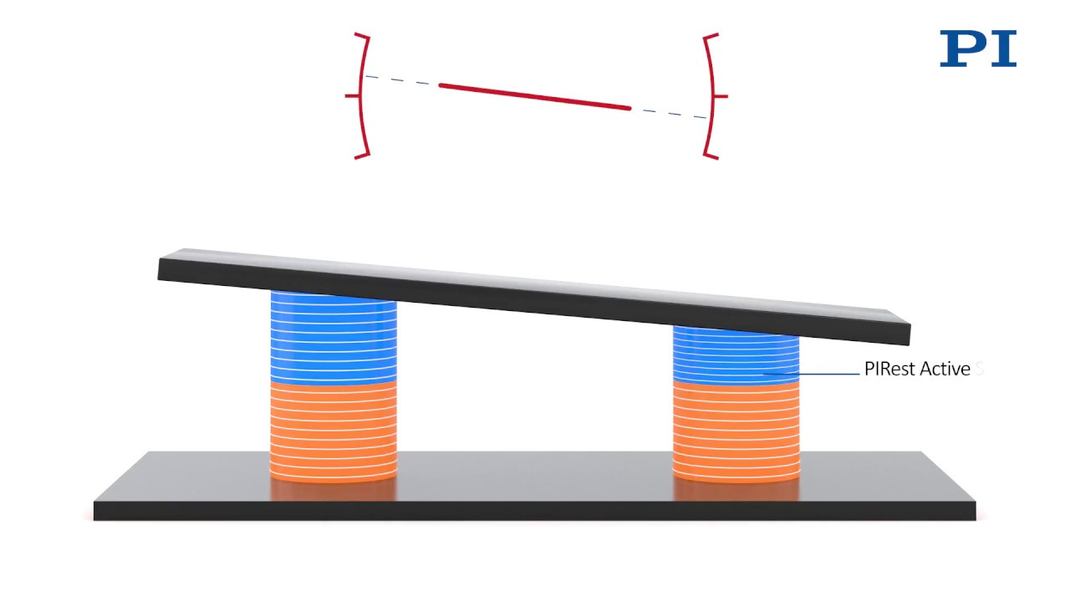

Applications for programmable (semi-active) shims can be found where the alignment between two or more subassemblies is critical and realignment may be required at some point due to environmental changes, creep or settling processes, etc.

Examples:

- Precision mechanical engineering

- High-end optical assemblies for astronomy and semiconductor manufacturing

- Material research test systems in synchrotrons

PIRest Technology

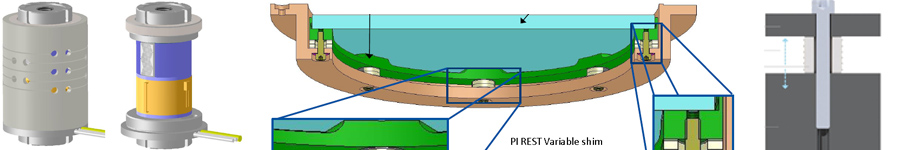

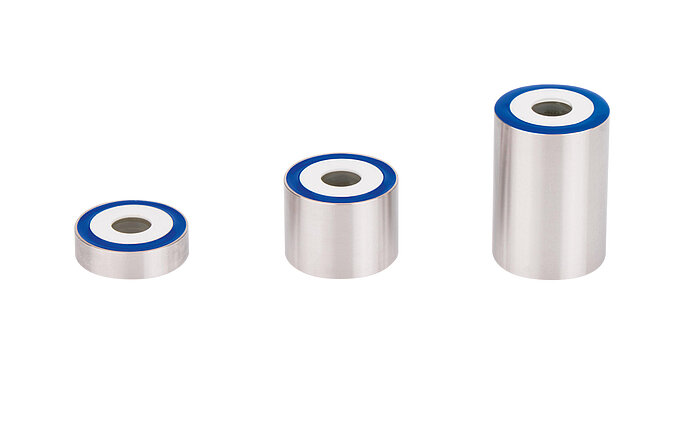

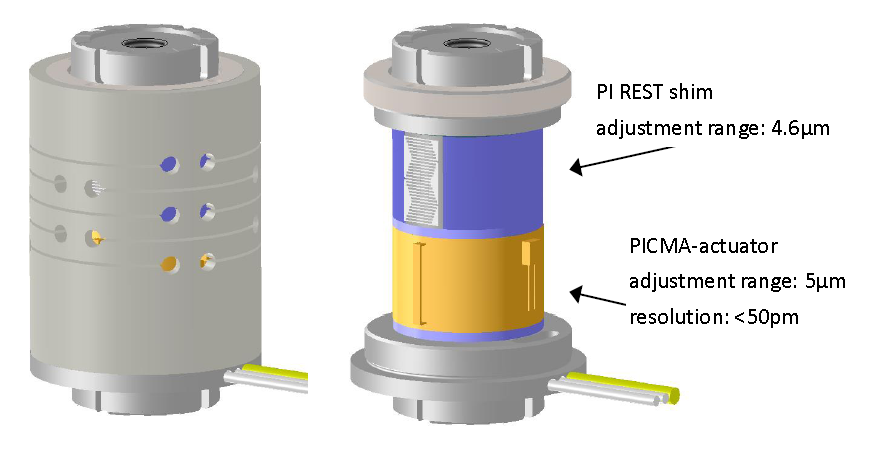

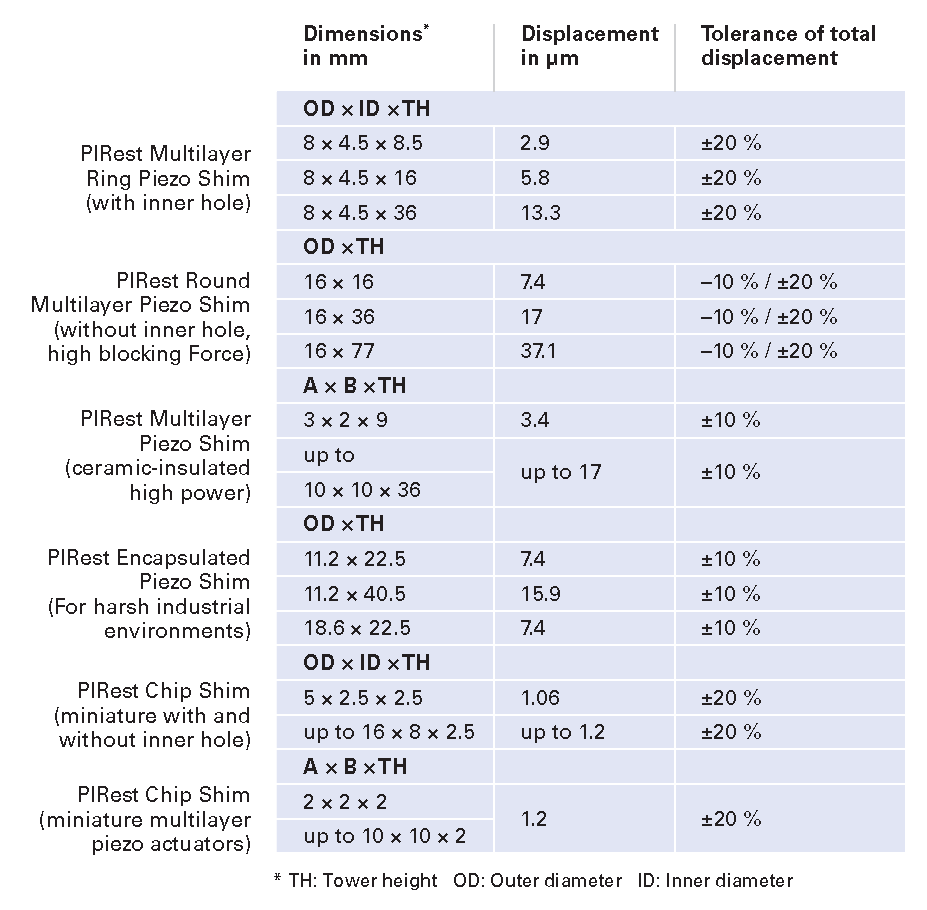

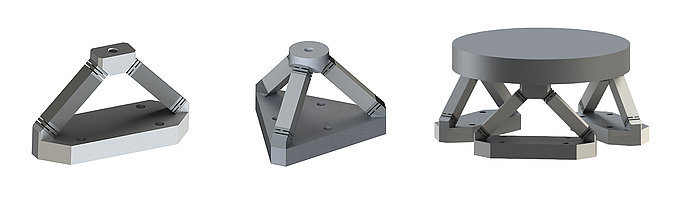

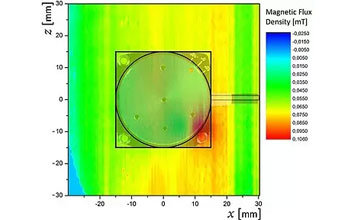

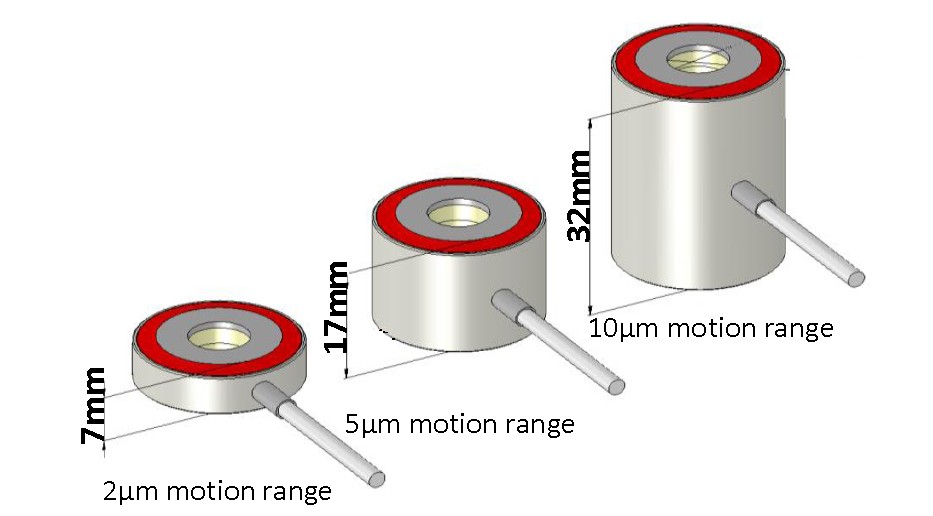

PIRest active shim technology is based on piezo ceramics and uses a hand-held programmer to change the displacement within seconds. Once a new position is programmed, the position is held stable to within nanometers over many days. These programmable shims can be made in virtually any shape and size such as plates or rings. Hybrid combinations with traditional piezo actuators for dynamic applications (e.g. vibration cancellation, precision motion control, etc.) are also feasible.

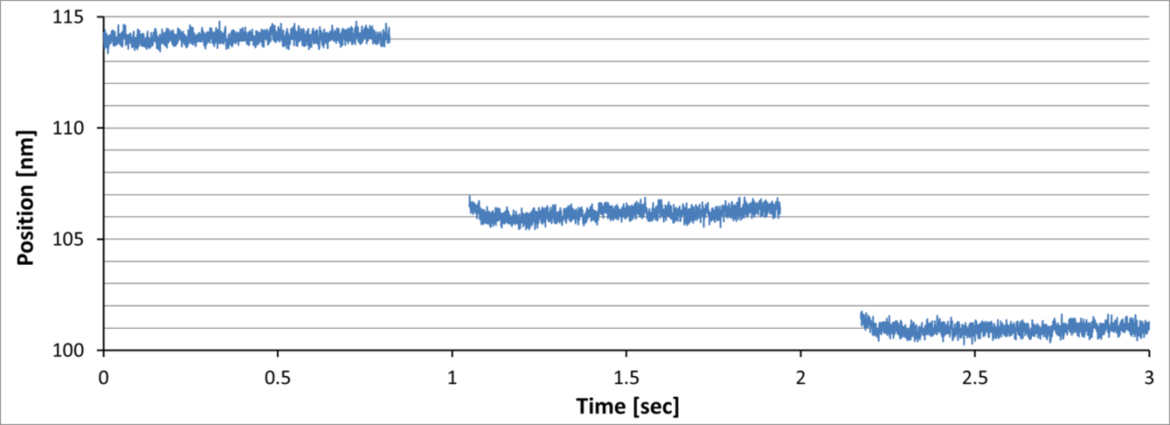

Nanometer Resolution

Since the piezoeffect allows for virtually unlimited resolution (which is why atomic force microscopes rely on piezo actuators), programmable dimensional changes in the nanometer range are feasible with the piezo shims.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy