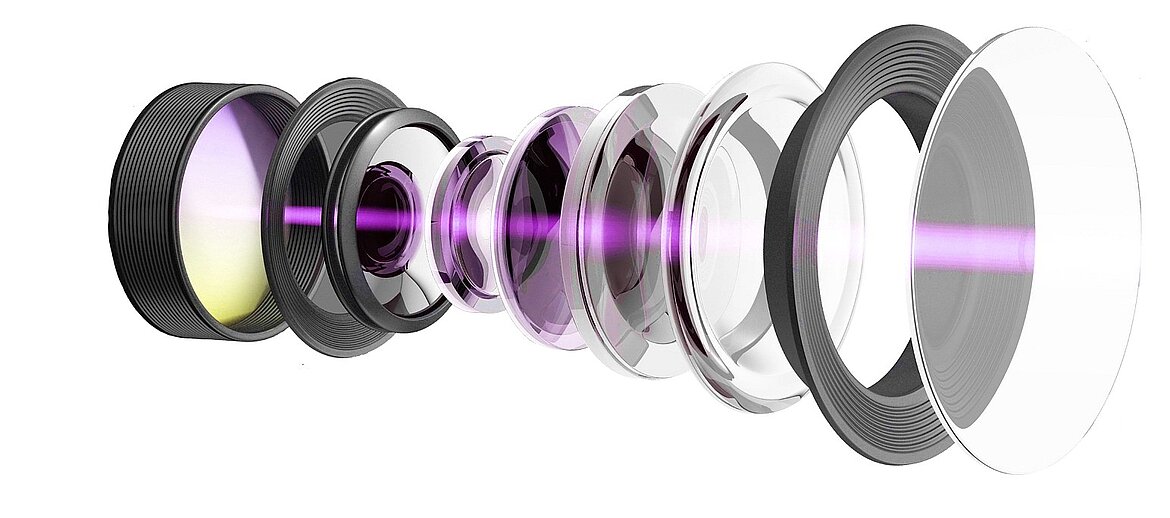

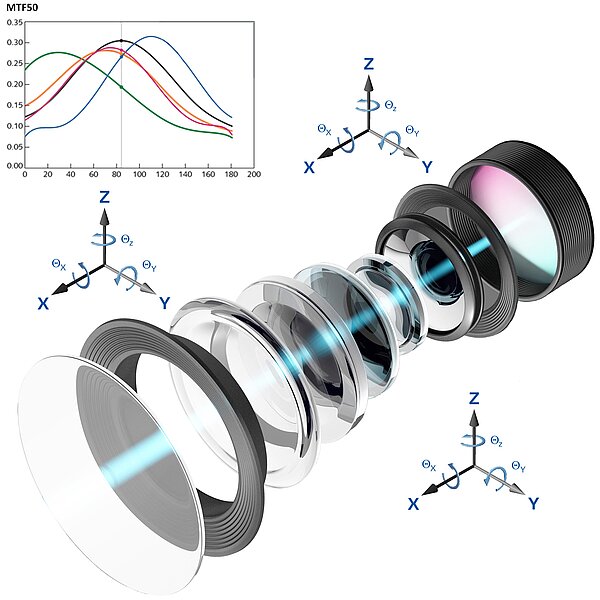

Optical alignment and micro-optic positioning are challenging, time-consuming processes. Tiny positional variations in photonic and optical manufacturing can mean the difference between success and failure. Nanoscale misalignments between the elements or inputs and outputs of an optical or photonic assembly can significantly impact its performance. This issue pervades numerous advanced opto-electronic manufacturing markets, from lenses in high-performance cameras and objectives, to lasers, to LIDAR assemblies, to silicon photonic wafers in semiconductor manufacturing.

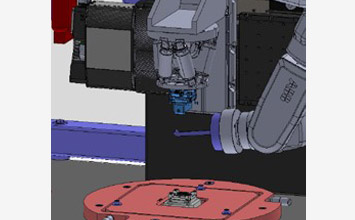

Active alignment is a technology that improves the performance, profitability and yield in manufacturing advanced optics and photonics components for the modern era. Conventionally, distinct elements within an optical system are aligned in a serial fashion through a series of time-consuming loops. This was to ensure the alignment was optimized across multiple degrees of freedom and that dependencies between elements were mitigated.

Despite a storied history of innovation in optical alignment, multi-channel active alignment is the first true leap forward in terms of manufacturing technology in three decades. While there have been numerous advancements in the field, each of these has conformed to the same basic principles: an alignment of one element or DOF is performed, then a small improvement in another element or DOF is attempted, requiring a re-optimization of the first item. This loop is then repeated, often dozens or hundreds of time— a very time-consuming and therefore, costly process. PI’s Fast Multi-channel Photonic Alignment technology leapfrogs this legacy approach by deploying intelligent parallel alignment algorithms within the firmware of the motion controllers. Upon command, these algorithms perform precision and often nanoscale motions to measure the contribution of each element’s misalignment in each DOF simultaneously and in parallel. The controllers autonomously adjust the elements until they reach the optimal position and orientation. Thus, one-step parallel optimization can replace the time-consuming loop formerly required.

There are myriad benefits to multi-channel optical active alignment.

Rapid & Reliable Positioning

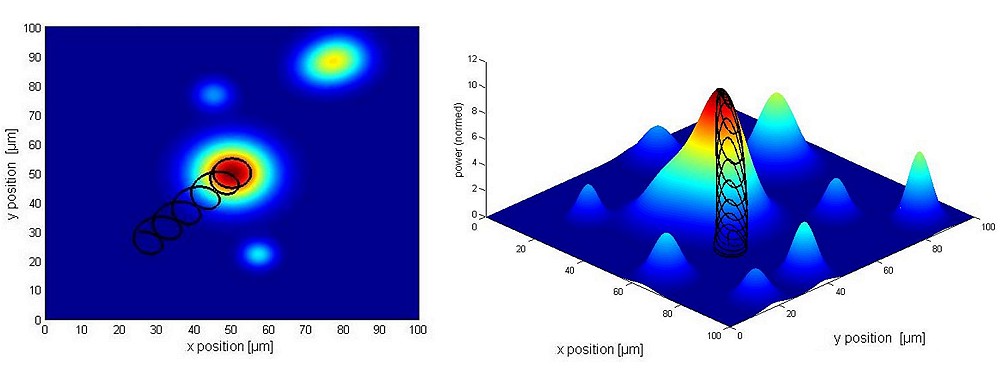

The breakthrough advantage of multi-channel active alignment is its ability to conduct parallel, or simultaneous, adjustments of multiple elements in multiple DOFs. Unique control algorithms in the controller firmware communicate with metrological and positional equipment to make autonomous adjustments to each element simultaneously. Within a single operation, the optimal position of each element is determined to achieve a global optimization for best overall performance. The subsequent speed increase for optical manufacturing is extraordinary.

Cost-Effective and Space Saving

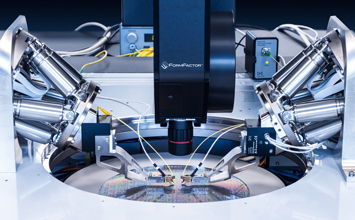

Parallelism in alignment is not only improving speed but also cutting cost and real estate required to run a manufacturing operation. With optical devices becoming more complex with each new generation, yet consumers expecting reduced costs, the speed and accuracy of parallel active alignment technology has the potential for reducing operating costs without compromising device quality. It plays a key role in advanced silicon photonics test and manufacturing procedures and can now be deployed in laser manufacturing and optical assembly.

Ultra-Precision Alignment

The exploratory motions of a multi-channel active alignment system can be programmed for micro- and nanoscale adjustments, with integrated parallel gradient search technology enabling the optimization of signal peaks within typically a single second. The system is especially beneficial in complex alignment situations, e.g. with arrays or multiple sequential components where interdependencies can cause overall signal degradation even when one path or component seems perfectly aligned.

Higher Yield Manufacturing

Automated assembly is a key target area for manufacturers looking to improve returns on investment (ROIs) by reducing operating expenses and increasing manufacturing yields. With parallel, active alignment technology, complex optimizations of multiple optical elements can often be consolidated into a single step. There is no need to sequentially improve the performance in a trial-and-error or looping fashion as was the case in legacy systems. This guarantees cost reductions and quality improvements by eliminating wasted time and compromises in performance.

The cost benefits of this are self-evident. The more complex the optical elements to be aligned, the higher the yield increase of the manufacturing process.

Active Alignment with PI

PI is a world leader in optical active alignment technology, pioneering Fast, Multi-Channel Photonics Alignment (FMPA) technology in numerous areas of application. We have recognized the potential for active alignment outside the photonics sector and have already applied the commercial benefits of this groundbreaking technology for optical cables, smartphone cameras, laser manufacturing, and much more.

If you would like to learn more about how active alignment technology speeds up manufacturing of optical systems, please do not hesitate to contact us directly.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy