In vitro diagnostics (IVD) opens up numerous possibilities to diagnose and detect diseases and other conditions at an early stage. Tests are performed using samples of blood, saliva, urine or tissue that have been taken from the body of humans or animals. In the fight against virus pandemics like the one we are experiencing at the moment with COVID-19, IVD testing is becoming increasingly important: fast, easy and widely accessible testing methods open up the possibility to adapt therapeutic interventions in terms of personalized medicine to help cure, treat, and prevent diseases.

What Methods of IVD Testing Are There?

Some IVD tests are designed to be used in laboratory settings while portable point-of-care devices can be used just about anywhere. Various analytical methods in the “Omics” such as whole genome sequencing and PCR (Polymerase Chain Reaction), but also molecular diagnostics tests like ELISA (Enzyme-linked Immunosorbent Assay) can be used for this purpose. Other techniques including cytometry, cell isolation, cell-line engineering, printing of microarrays and lab-on-a-chip systems also emerge in the context of IVD methods.

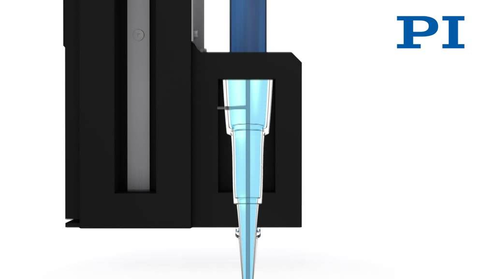

Not an Easy Task: Liquid Handling for IVD

The requirements of fluid handling in IVD devices are extremely demanding: very small volumes of liquids with different characteristics have to be dosed or moved with high precision. The technology used must be able to implement shock-free dosing, fast mixing or separation of fluids and particles as well as the generation of perfect droplets, taking into account the viscosity and surface tension of the media and the dosing speed. Mixing or sorting tasks are often executed contactlessly to avoid contamination of the samples.

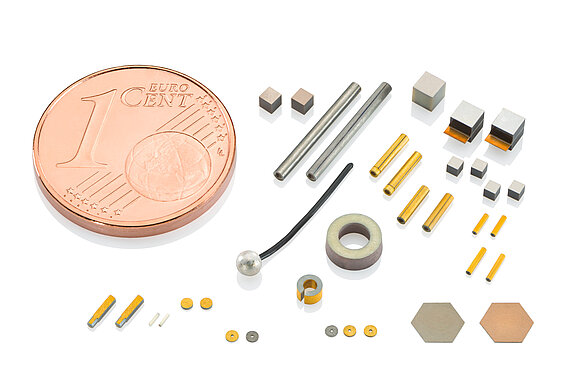

The actuators used for nanoliter or picoliter liquid handling devices must work at high operating frequencies of up to several kHz while at the same time producing the kinetic energy required to generate small fluid flows or tiny droplets. Piezoelectric components and actuators are suitable products for these challenging demands: the piezoelectric effect is based on the generation of charges through the application of force by a crystal and vice versa, therefore piezo components work with instantaneous displacement by admitting a voltage. These components mostly operate with low power consumption suitable for battery-driven devices and exhibit durability as well as reliability, making them suitable to be employed in point-of-care applications as well as large lab automation devices.

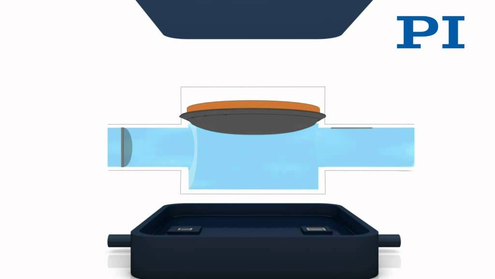

Piezoceramic Components for Micro Pumps

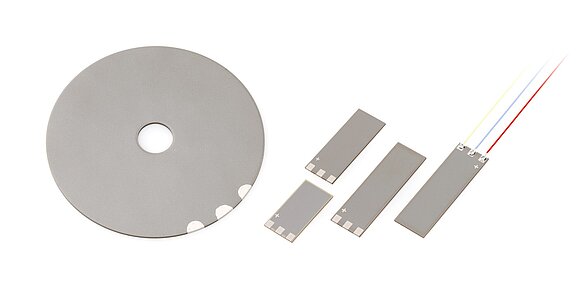

Piezoelectric microfluidic devices are used for distribution tasks whenever small volumes in the milliliter to picoliter range have to be controlled. >> Piezo components such as plates and discs are suitable products for microfluidic devices requiring shock-free pumping of small fluid volumes over a certain period of time. To transfer their bending displacement to fluid chambers moving liquids, the piezo components can be glued on substrates. Miniaturized plates work as actuators in light-weight micro pumps with dimensions of less than one millimeter, which can be integrated in portable point-of-care-devices.

Energy-Efficient Piezo Valves

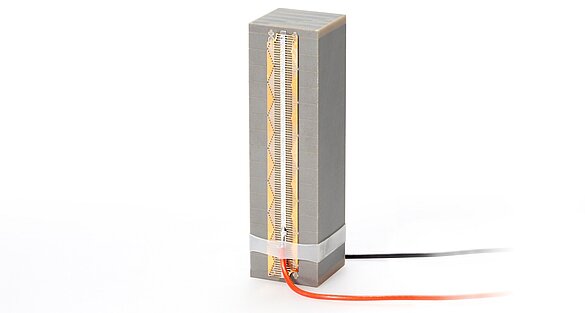

Besides pumps, valves are often used in IVD microfluidic devices. Piezo valves are highly suitable for these applications: The piezo actuators switch the valve directly, and are able to work against a closing spring or a flexible tube for volume displacement. Even with very low power, the piezo valve will maintain its current position – energy is only needed when the shape of the piezo element has to be changed. Piezoelectric valves can be designed with >> PICMA® Multilayer Bending Actuators exhibiting displacement of up to a few millimeters depending on their design. Due to the low layer thickness in these actuators, their low energy consumption makes piezo benders ideal for battery-operated point-of-care devices. The piezo actuators ensure very low flow rates that can be controlled by the driving voltage of the piezo using proportional technology.

Mixing Fluids with the Power of the Piezo

Piezoelectric components enable active mixing of fluids in a small space. To this end, >> miniaturized piezo discs or plates with dimensions of less than one millimeter are placed on top of microfluidic channels. As the piezo operates, acoustic waves are formed, allowing for several media to be mixed. The mechanical forces of the waves induce turbulences that lead to mixing even in thin capillaries usually only permitting laminar flow.

Using piezo components made of hard piezoelectric materials, it is possible to generate cavitation in the liquid with power ultrasound. The resulting cavitation bubbles also lead to turbulences and mixing effects in microfluidic devices.

Another technique of active mixing is induced by >> piezoelectric discs working in a bending mode: With upward and downward motion similar to that of membrane pumps, these tiny actuators create vortexes in microfluidic chambers.

Ultrafast Actuators for Sorting Tasks

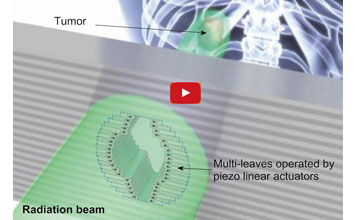

The sorting or separation of cells and nanoparticles in fluids is a major task in many IVD devices. Piezoelectric multilayer actuators such as >> PICMA® Stacks manage it with ultrahigh accelerations and low driving voltages. Due to their displacement with nanometer precision and reaction time of microseconds, fluid or gas interfaces are manipulated very fast so that cells can be selected and separated from others.

Piezoelectric discs can also be used for acoustofluidic sorting methods. Similar to the mixing mode, the mechanical force of ultrasonic waves is used to manipulate small particles such as cells and microorganisms. Here, surface or bulk acoustic waves originating from piezoelectric components can be used.

A Thousand Droplets per Second

>> Piezoelectric tubes can be used for sorting tasks with precise droplet generation. By placing a glass capillary inside such a piezo tube, the ink-jet principle can be used to dispense droplets down to picoliter volume. Single cell isolation is achieved with the appropriate dosage of the droplets.

PICMA® Stack piezo actuators offer an alternative to piezo tubes: By placing them in a printing head, micro assays can be produced in a very high speed with high accuracy.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy